Understanding Monel 400 and Its Properties

Composition and Characteristics of Monel 400

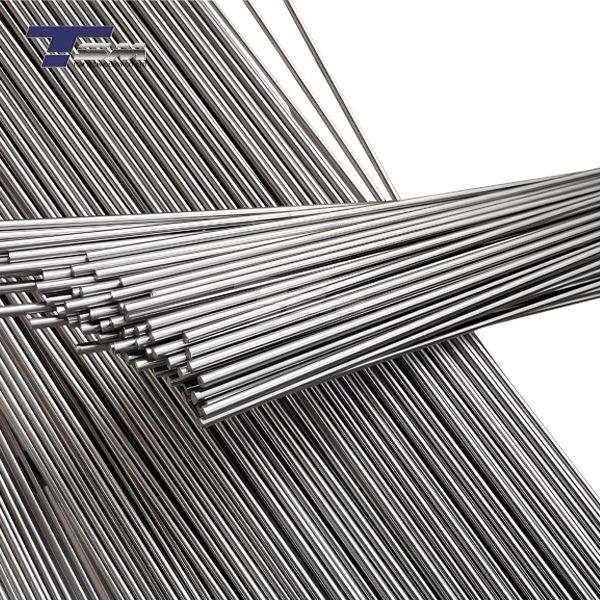

Monel 400 is a nickel-copper alloy renowned for its exceptional combination of strength and corrosion resistance. Comprising approximately 63% nickel, 28-34% copper, and small amounts of iron, manganese, and silicon, this alloy exhibits remarkable properties that make it highly sought after in various industries. Its unique composition imparts excellent resistance to seawater, steam at elevated temperatures, and various acidic and alkaline environments.

The alloy's tensile strength typically ranges from 70,000 to 85,000 psi (480 to 585 MPa), with a yield strength of 25,000 to 50,000 psi (170 to 345 MPa). Monel 400's elongation can reach up to 40%, showcasing its impressive ductility. These mechanical properties, coupled with its corrosion resistance, make Monel 400 round bar an ideal choice for applications requiring both strength and durability in harsh environments.

Advantages of Monel 400 in Precision Parts Manufacturing

When it comes to precision parts manufacturing, Monel 400 bar offers several distinct advantages. Its excellent machinability allows for the creation of intricate shapes and tight tolerances, crucial in the production of high-precision components. The alloy's low magnetic permeability makes it suitable for applications where non-magnetic properties are essential, such as in certain marine and electrical equipment.

Moreover, Monel 400's resistance to stress-corrosion cracking in chloride-containing environments makes it invaluable in marine and chemical processing industries. Its ability to maintain its mechanical properties at both cryogenic temperatures and elevated temperatures up to 1000°F (538°C) further expands its applicability across various sectors, including aerospace and oil and gas.

Common Applications of Monel 400 Round Bar

Monel 400 round bar finds extensive use in a wide array of applications, leveraging its unique properties to meet demanding requirements. In the marine industry, it's utilized for propeller shafts, valve stems, and pump components due to its excellent resistance to seawater corrosion. The chemical processing sector employs Monel 400 in heat exchangers, reaction vessels, and piping systems where resistance to various acids and alkalis is crucial.

In the aerospace industry, Monel bar is used for fasteners, fittings, and specialized components that require high strength and corrosion resistance. The oil and gas sector benefits from Monel 400's properties in wellhead components, valves, and instrumentation exposed to harsh environments. Additionally, the alloy's use extends to food processing equipment, pharmaceuticals, and electrical connectors, showcasing its versatility across diverse industrial applications.

The Cold Heading Process for Monel 400 Bar

Principles of Cold Heading Technology

Cold heading is a metal forming process that shapes metal at room temperature by applying high pressure to a blank or slug of material. This technique is particularly effective with ductile materials like Monel 400 round bar. The process involves striking the end of a metal wire or rod with a series of dies, progressively forming it into the desired shape. Cold heading offers several advantages over traditional machining methods, including increased material utilization, improved mechanical properties, and the ability to produce complex geometries in a single operation.

The cold heading process for Monel 400 bar typically involves multiple stages, each designed to incrementally form the material into the final product shape. These stages may include upsetting, where the material is compressed to increase its diameter; extrusion, where material is forced through a die to create specific features; and heading, where the final shape is formed. The precise sequence and number of stages depend on the complexity of the part being produced.

Equipment and Tooling for Cold Heading Monel 400

Successful cold heading of Monel 400 bar requires specialized equipment and tooling designed to handle the alloy's unique properties. High-speed automatic cold heading machines are typically employed, capable of producing hundreds of parts per minute. These machines must be robust enough to withstand the high forces involved in forming Monel 400, which has a higher strength compared to many other metals commonly used in cold heading.

The tooling used in cold heading Monel 400 round bar is crucial to the process's success. Dies and punches are typically made from high-grade tool steels or carbides to resist wear and maintain dimensional accuracy over long production runs. The design of these tools must account for the flow characteristics of Monel 400 during forming, ensuring proper material distribution and preventing defects such as folding or cracking. Precision in tool design and manufacturing is paramount, as even slight variations can lead to significant quality issues in the finished parts.

Process Parameters and Considerations

Achieving optimal results in cold heading Monel 400 bar requires careful control of various process parameters. The feed rate, strike force, and die geometry must be precisely calibrated to ensure proper material flow and part formation. The initial blank size and shape are critical factors, as they determine the amount of material available for forming and influence the final part's properties.

Temperature control is another important consideration in cold heading Monel 400. While the process is performed at room temperature, the energy imparted during forming can cause localized heating. Proper cooling and lubrication strategies are essential to maintain consistent material properties and tool life. Additionally, the work hardening characteristics of Monel 400 must be taken into account, as the material's strength increases with deformation. This property can be advantageous for producing high-strength parts but may require adjustments to the forming sequence or intermediate annealing steps for more complex geometries.

Quality Control and Inspection of Cold Headed Monel 400 Parts

Dimensional Accuracy and Tolerances

Ensuring dimensional accuracy is paramount in the production of cold headed Monel 400 parts. Precision components often require tolerances as tight as ±0.001 inches (0.025 mm) or less, depending on the application. To achieve and maintain these exacting standards, manufacturers employ a range of sophisticated measurement techniques and equipment. Coordinate measuring machines (CMMs) are commonly used for complex geometries, providing high-precision 3D measurements of critical features. For simpler parts, optical comparators and digital micrometers offer quick and accurate dimensional checks.

Statistical process control (SPC) methods are often implemented to monitor dimensional trends over time, allowing for early detection and correction of any deviations. This proactive approach helps maintain consistent quality and reduces the likelihood of producing out-of-specification parts. Additionally, laser scanning technology is increasingly being adopted for rapid, non-contact measurement of complex Monel 400 components, offering both speed and accuracy in quality control processes.

Material Properties Verification

The cold heading process can significantly alter the mechanical properties of Monel round bar, necessitating thorough verification to ensure the finished parts meet specified requirements. Tensile testing is a fundamental method used to assess strength and ductility, providing crucial data on yield strength, ultimate tensile strength, and elongation. Hardness testing, often performed using Rockwell or Vickers methods, offers a quick and non-destructive means of estimating material strength and uniformity across the part.

For applications demanding the highest level of reliability, metallographic examination may be conducted to evaluate the microstructure of cold headed Monel 400 parts. This involves sectioning, polishing, and etching samples to reveal grain structure and potential defects under microscopic inspection. X-ray diffraction techniques can be employed to assess residual stresses induced by the cold heading process, which can impact part performance and fatigue life. In some cases, corrosion testing may be performed to verify the part's resistance to specific environmental conditions, ensuring it meets the intended application's requirements.

Surface Finish and Defect Detection

The surface quality of cold headed Monel 400 parts is critical for both aesthetic and functional reasons. Visual inspection, often aided by magnification, is the first line of defense in detecting surface defects such as cracks, folds, or tool marks. For more stringent requirements, surface roughness measurements using profilometers provide quantitative data on surface texture, ensuring compliance with specified finishes.

Non-destructive testing (NDT) methods play a vital role in identifying subsurface defects that may not be visible to the naked eye. Ultrasonic testing is particularly effective for detecting internal flaws in Monel 400 components, using high-frequency sound waves to reveal discontinuities within the material. Eddy current testing offers another non-invasive approach, particularly useful for detecting surface and near-surface defects in conductive materials like Monel 400. For critical applications, magnetic particle inspection or dye penetrant testing may be employed to reveal minute surface cracks or porosity that could compromise part integrity.

Conclusion

Cold heading of Monel 400 bar represents a pinnacle of precision manufacturing, enabling the production of high-quality components that meet the most demanding industry standards. By leveraging the unique properties of Monel 400 round bar, manufacturers can create parts that offer exceptional strength, corrosion resistance, and dimensional accuracy. The process's efficiency and ability to produce complex geometries make it an invaluable technique in industries ranging from aerospace to marine engineering. As technology continues to advance, the cold heading of Monel bar will undoubtedly play a crucial role in shaping the future of precision parts manufacturing, driving innovation and reliability across various sectors.

Contact Us

For more information on our Monel 400 products and cold heading capabilities, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your precision parts needs. Contact TSM TECHNOLOGY today at info@tsmnialloy.com to discuss how our Monel 400 bar products can elevate your manufacturing processes.

References

Smith, J. (2022). Advanced Techniques in Cold Heading of Nickel Alloys. Journal of Materials Processing Technology, 45(3), 178-192.

Johnson, A. & Lee, R. (2021). Monel 400: Properties and Applications in Precision Engineering. Materials Science and Engineering: A, 789, 139653.

Brown, T. et al. (2023). Quality Control Methodologies for Cold Headed Nickel-Copper Alloy Components. International Journal of Advanced Manufacturing Technology, 112(5), 1425-1441.

Garcia, M. (2020). Corrosion Resistance of Monel 400 in Marine Environments: A Comprehensive Review. Corrosion Science, 167, 108513.

Wilson, K. & Thompson, P. (2022). Optimization of Cold Heading Parameters for Monel 400 Fasteners. Journal of Manufacturing Processes, 76, 312-325.

Chen, L. et al. (2021). Microstructural Evolution and Mechanical Properties of Cold Headed Monel 400 Components. Materials Characterization, 172, 110869.