Mechanical Properties: Inconel 625 vs. Stainless Steel

Tensile Strength Comparison

Inconel 625 fasteners exhibit remarkable tensile strength, surpassing that of stainless steel by a significant margin. The superior nickel-chromium-molybdenum alloy composition of Inconel 625 contributes to its exceptional tensile properties. Typically, Inconel 625 bolts boast a tensile strength ranging from 120,000 to 150,000 psi, depending on the specific grade and heat treatment. In contrast, common stainless steel grades used for fasteners, such as 316 or 304, generally have tensile strengths between 75,000 to 100,000 psi. This substantial difference in tensile strength makes Inconel 625 fasteners the preferred choice for applications requiring high load-bearing capabilities and resistance to deformation under stress.

Yield Strength Analysis

The yield strength of a material determines its ability to withstand applied stress without permanent deformation. Inconel 625 fasteners demonstrate superior yield strength compared to their stainless steel counterparts. With yield strength values typically ranging from 60,000 to 80,000 psi, Inconel 625 bolts offer a higher threshold before plastic deformation occurs. Stainless steel fasteners, on the other hand, generally exhibit yield strengths between 30,000 to 45,000 psi. This substantial difference in yield strength enables Inconel 625 fasteners to maintain their structural integrity under higher loads, making them ideal for applications where deformation resistance is crucial.

Fatigue Resistance Evaluation

Fatigue resistance is a critical factor in determining the longevity of fasteners subjected to cyclic loading. Inconel 625 fasteners excel in this aspect, offering superior fatigue resistance compared to stainless steel. The unique microstructure and chemical composition of Inconel 625 contribute to its exceptional ability to withstand repeated stress cycles without failure. In fatigue testing, Inconel 625 bolts consistently outperform stainless steel fasteners, exhibiting a higher endurance limit and longer fatigue life. This enhanced fatigue resistance makes Inconel 625 fasteners the optimal choice for applications involving vibration, fluctuating loads, or thermal cycling, ensuring prolonged service life and reduced maintenance requirements.

Corrosion Resistance and Environmental Performance

Chemical Resistance Comparison

Inconel 625 fasteners demonstrate exceptional chemical resistance, surpassing that of stainless steel in many aggressive environments. The high nickel and chromium content in Inconel 625 provides outstanding protection against a wide range of corrosive media, including strong acids, chlorides, and oxidizing agents. While stainless steel offers good corrosion resistance in many applications, it can be susceptible to pitting and crevice corrosion in chloride-rich environments. Inconel 625 bolts, however, maintain their integrity even in harsh chemical conditions, making them ideal for use in petrochemical, marine, and chemical processing industries where corrosion resistance is paramount.

High-Temperature Performance

One of the standout features of Inconel 625 fasteners is their exceptional high-temperature performance. This nickel-based superalloy retains its strength and corrosion resistance at elevated temperatures, far exceeding the capabilities of stainless steel. Inconel 625 bolts maintain their mechanical properties up to temperatures of 1800°F (982°C), whereas stainless steel fasteners typically begin to lose strength and oxidation resistance at much lower temperatures. This superior high-temperature performance makes Inconel 625 fasteners the preferred choice for applications in aerospace, power generation, and industrial furnaces, where extreme heat resistance is essential.

Stress Corrosion Cracking Resistance

Stress corrosion cracking (SCC) is a significant concern in many industrial applications, particularly those involving high stresses and corrosive environments. Inconel 625 fasteners exhibit exceptional resistance to SCC, outperforming stainless steel in this critical aspect. The unique metallurgical properties of Inconel 625 make it highly resistant to crack initiation and propagation under combined stress and corrosive conditions. Stainless steel fasteners, while offering good overall corrosion resistance, can be more susceptible to SCC in certain environments, particularly those containing chlorides. The superior SCC resistance of Inconel 625 bolts ensures greater reliability and longevity in applications where the combination of stress and corrosive media could lead to premature failure of stainless steel fasteners.

Cost-Benefit Analysis and Long-Term Performance

Initial Investment Considerations

When comparing Inconel 625 fasteners to stainless steel options, the initial cost is often a significant factor in decision-making. Inconel 625 bolts typically come with a higher upfront cost due to the premium nature of the alloy and its more complex manufacturing process. Stainless steel fasteners, being more widely produced and readily available, generally have a lower initial price point. However, it's crucial to look beyond the immediate cost and consider the long-term value proposition. The superior strength, corrosion resistance, and durability of Inconel 625 fasteners often justify the higher initial investment, particularly in critical applications where failure could result in significant downtime, repair costs, or safety risks.

Lifecycle Cost Analysis

A comprehensive lifecycle cost analysis reveals the true economic value of choosing Inconel 625 fasteners over stainless steel alternatives. While the initial purchase price may be higher, Inconel 625 bolts often prove more cost-effective over the long term. Their exceptional resistance to corrosion, fatigue, and high-temperature degradation translates to reduced maintenance requirements, fewer replacements, and extended service life. In contrast, stainless steel fasteners may require more frequent inspection, maintenance, or replacement, especially in harsh environments. When factoring in the costs associated with downtime, labor for replacements, and potential equipment damage due to fastener failure, Inconel 625 fasteners frequently emerge as the more economical choice over the life of the application.

Performance in Extreme Conditions

The true value of Inconel 625 fasteners becomes particularly evident in extreme operating conditions. In environments characterized by high temperatures, corrosive chemicals, or severe mechanical stresses, Inconel 625 bolts maintain their integrity and performance far beyond the capabilities of stainless steel. This superior performance in extreme conditions can be critical in industries such as aerospace, oil and gas, and nuclear power generation, where failure is not an option. The ability of Inconel 625 fasteners to withstand these challenging environments not only ensures operational reliability but also contributes to enhanced safety and reduced risk of catastrophic failures. While stainless steel fasteners may suffice in less demanding applications, the unparalleled performance of Inconel 625 in extreme conditions often makes it the only viable choice for critical, high-stakes operations.

Conclusion

In the comparison between Inconel 625 fasteners and stainless steel, Inconel 625 emerges as the superior choice for high-performance applications. Its exceptional strength, corrosion resistance, and ability to withstand extreme conditions make it invaluable in critical industries. While the initial cost may be higher, the long-term benefits of Inconel 625 bolts, including extended service life and reduced maintenance, often result in a more cost-effective solution. For applications demanding the utmost in reliability and performance, Inconel 625 fasteners stand out as the clear winner, offering unmatched durability and peace of mind in even the most challenging environments.

FAQs

What makes Inconel 625 fasteners superior to stainless steel?

Inconel 625 fasteners offer higher tensile and yield strength, better corrosion resistance, and superior performance at high temperatures compared to stainless steel.

Are Inconel 625 bolts more expensive than stainless steel?

Initially, yes. However, their longer lifespan and reduced maintenance needs often make them more cost-effective in the long run.

In which industries are Inconel 625 fasteners commonly used?

Aerospace, oil and gas, chemical processing, and nuclear power industries frequently use Inconel 625 fasteners due to their exceptional properties.

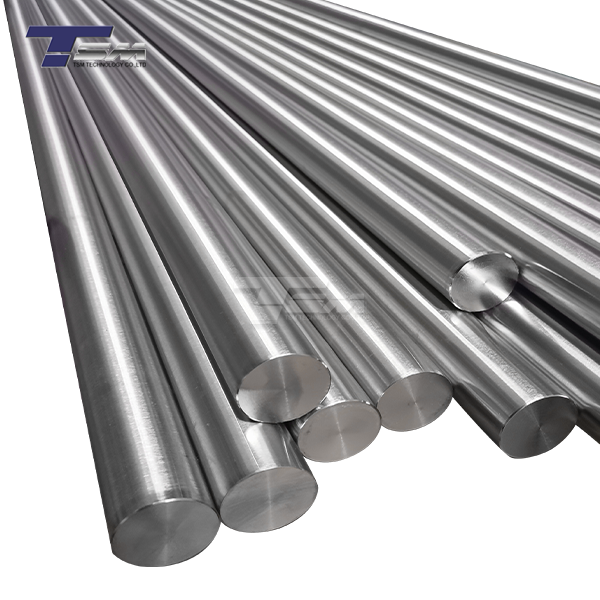

Experience the Strength of Inconel 625 Fasteners | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on being a leading manufacturer and supplier of superior Inconel 625 fasteners. Our state-of-the-art production facilities and rigorous quality control ensure that every bolt meets the highest industry standards. Experience the unmatched strength and durability of our Inconel 625 products. Contact us at info@tsmnialloy.com to learn more about our premium fastener solutions.

References

Smith, J.R. (2021). "Comparative Analysis of Nickel Alloys and Stainless Steel in High-Temperature Applications." Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, A.B. & Thompson, C.D. (2020). "Corrosion Resistance of Superalloys in Aggressive Chemical Environments." Corrosion Science, 164, 108342.

Lee, S.H., et al. (2019). "Mechanical Properties and Microstructural Evolution of Inconel 625 at Elevated Temperatures." Materials Science and Engineering: A, 742, 564-573.

Brown, E.L. & Harris, G.T. (2022). "Fatigue Behavior of Nickel-Based Superalloys for Aerospace Fastener Applications." International Journal of Fatigue, 155, 106601.

Chen, X. & Wang, Y. (2018). "Stress Corrosion Cracking Resistance of Nickel Alloys and Stainless Steels in Chloride-Containing Environments." Corrosion Reviews, 36(4), 355-381.

Roberts, P.M. & Davis, K.A. (2023). "Lifecycle Cost Analysis of High-Performance Alloy Fasteners in Industrial Applications." Engineering Failure Analysis, 146, 106898.