- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Comparing Inconel 718 vs 625: Key Differences and Use Cases

When it comes to high-performance nickel-based superalloys, Inconel 718 and Inconel 625 stand out as two of the most widely used materials in demanding industrial applications. Both alloys offer exceptional strength, corrosion resistance, and heat tolerance, but they have distinct characteristics that make them suitable for different use cases. This comprehensive comparison will delve into the key differences between Inconel 718 and 625, exploring their unique properties, advantages, and typical applications. By understanding the strengths and limitations of each alloy, engineers and manufacturers can make informed decisions when selecting the most appropriate material for their specific needs in aerospace, marine, chemical processing, and other challenging environments.

Composition and Properties: Understanding the Foundations

Chemical Composition: The Building Blocks of Performance

Inconel 718 and 625 have distinct chemical compositions that contribute to their unique properties. Inconel 718 contains higher levels of aluminum and titanium, which form strengthening precipitates during heat treatment. In contrast, Inconel 625 has a higher molybdenum content, enhancing its corrosion resistance.

Inconel 718 vs Inconel 625 Chemical Composition (Weight %) Comparison

| Element | Inconel 718 | Inconel 625 |

|---|---|---|

| Nickel (Ni) | 50–55% | ≥ 58% |

| Chromium (Cr) | 17–21% | 20–23% |

| Iron (Fe) | Balance | ≤ 5% |

| Niobium (Nb) | 4.75–5.5% | 3.15–4.15% |

| Molybdenum (Mo) | 2.8–3.3% | 8–10% |

| Titanium (Ti) | 0.65–1.15% | ≤ 0.4% |

| Aluminum (Al) | 0.2–0.8% | ≤ 0.4 |

Mechanical Properties: Strength Under Pressure

Both alloys exhibit excellent mechanical properties, but Inconel 718 generally offers higher strength and hardness. This is due to its ability to be precipitation hardened, resulting in superior tensile and yield strengths. Inconel 625, while slightly lower in strength, maintains better ductility and is often preferred for its exceptional weldability.

Typical mechanical properties at room temperature:

Inconel 718:

- Tensile Strength: 1,240 MPa

- Yield Strength: 1,034 MPa

- Elongation: 12%

Inconel 625:

- Tensile Strength: 827 MPa

- Yield Strength: 414 MPa

- Elongation: 30%

Corrosion Resistance: Battling Harsh Environments

While both alloys offer excellent corrosion resistance, Inconel 625 has a slight edge in this area. Its higher molybdenum content provides superior resistance to pitting and crevice corrosion, especially in chloride-containing environments. Inconel 718, however, still maintains impressive corrosion resistance and is often chosen for its balance of strength and corrosion properties.

Heat Treatment and Workability: Shaping Performance

Heat Treatment Processes: Unlocking Potential

The heat treatment process is a critical factor in distinguishing Inconel 718 from 625. Inconel 718 undergoes a complex precipitation hardening process, typically involving solution annealing followed by a two-step aging treatment. This process forms strengthening precipitates, significantly enhancing its mechanical properties.

Inconel 625, on the other hand, is primarily used in the solution-annealed condition. While it can be work-hardened, it doesn't respond to precipitation hardening in the same way as Inconel 718. This difference in heat treatment capability is a key factor in selecting between the two alloys for specific applications.

Machinability and Formability: Challenges in Manufacturing

Both Inconel 718 and 625 are known for their challenging machinability due to their high strength and work-hardening tendencies. However, Inconel 718 is generally considered slightly easier to machine, especially in its annealed state before age hardening.

In terms of formability, Inconel 625 has an advantage due to its higher ductility and lower yield strength. This makes it more suitable for applications requiring complex forming operations or where weldability is a primary concern.

Welding Considerations: Joining Forces

Welding is a critical aspect of fabrication for many applications. Inconel 625 is renowned for its excellent weldability, making it a preferred choice for applications requiring extensive welding or for use as a welding filler material. Its resistance to hot cracking and ability to maintain strength and corrosion resistance in the as-welded condition are significant advantages.

Inconel 718, while weldable, requires more careful control of welding parameters and post-weld heat treatment to achieve optimal properties. The precipitation hardening nature of Inconel 718 can lead to challenges in maintaining consistent properties across weld zones.

Applications and Industry Use: Putting Theory into Practice

Aerospace and Gas Turbines: Soaring to New Heights

Inconel 718 shines in aerospace applications, particularly in gas turbine engines. Its high strength-to-weight ratio and excellent fatigue resistance make it ideal for components such as turbine disks, shafts, and fasteners. The ability to maintain strength at elevated temperatures (up to about 650°C) is crucial in these demanding environments.

While Inconel 625 is also used in aerospace, it's more commonly found in exhaust systems, thrust reversers, and other components where corrosion resistance is paramount. Its superior weldability makes it suitable for fabricating complex structures in aircraft.

Oil and Gas Industry: Diving Deep

In the oil and gas sector, both alloys find extensive use, but often in different applications. Inconel 625 is widely used in subsea equipment, risers, and downhole components due to its exceptional corrosion resistance in chloride-rich environments. Its ability to withstand sour gas (H2S) environments makes it particularly valuable in offshore operations.

Inconel 718, with its higher strength, is often chosen for wellhead components, valve stems, and other high-stress applications in oil and gas extraction. Its resistance to stress corrosion cracking in chloride environments, combined with its strength, makes it suitable for critical components in high-pressure, high-temperature (HPHT) wells.

Chemical Processing: Resisting Corrosion

In chemical processing industries, the choice between Inconel 718 and 625 often depends on the specific corrosive environment and mechanical requirements. Inconel 625 is frequently used in chemical processing equipment, heat exchangers, and reaction vessels due to its superior corrosion resistance across a wide range of aggressive media.

Inconel 718 finds applications in chemical processing where higher strength is required, such as in high-pressure vessels or components subject to significant mechanical stress. Its ability to maintain properties at elevated temperatures also makes it suitable for certain high-temperature chemical processing applications.

Conclusion

The choice between Inconel 718 and Inconel 625 depends on the specific requirements of the application. Inconel 718 excels in high-strength, moderate-temperature applications, making it ideal for aerospace and high-stress components. Its precipitation hardening capability allows for tailored mechanical properties, but it requires careful heat treatment and welding procedures. Inconel 625, with its superior corrosion resistance and excellent weldability, is the go-to choice for applications in highly corrosive environments or where extensive fabrication is needed. Both alloys continue to play crucial roles in advancing technology across various industries, from the depths of the ocean to the heights of aerospace engineering.

FAQs

What are the main differences between Inconel 718 and 625?

The main differences lie in their chemical composition, strength, and corrosion resistance. Inconel 718 offers higher strength due to its precipitation hardening capability, while Inconel 625 provides superior corrosion resistance and weldability.

Which alloy is better for high-temperature applications?

Both alloys perform well at high temperatures, but Inconel 718 typically maintains its strength better up to about 650°C, making it preferred for many high-temperature aerospace applications.

Can Inconel 625 be used in marine environments?

Yes, Inconel 625 is excellent for marine applications due to its outstanding resistance to chloride-induced pitting and crevice corrosion.

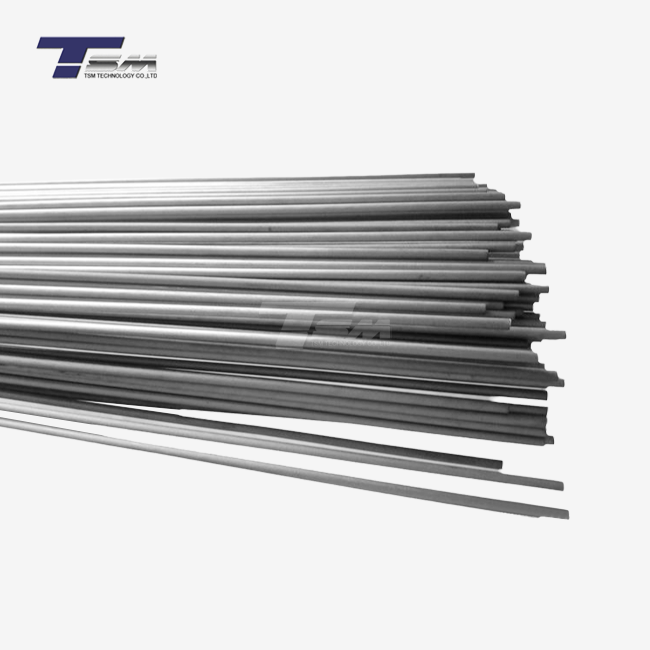

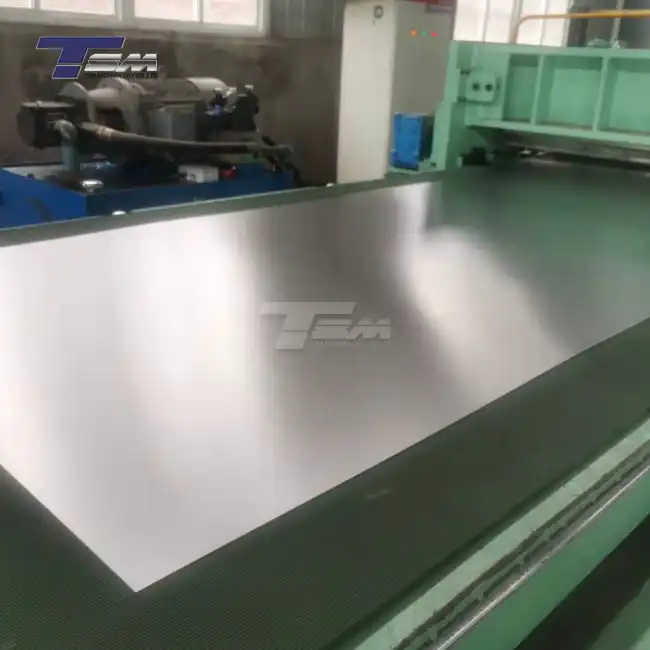

Superior Nickel Alloy Solutions for Your Industry | TSM Technology

At TSM Technology, we specialize in providing high-quality Inconel 718, Inconel 625, and other superior nickel alloys to meet your specific industry needs. As a leading manufacturer and supplier, we offer a wide range of shapes and custom solutions. Our strict quality control ensures each product meets the highest standards. For expert advice on selecting the right alloy for your application, contact our team at info@tsmnialloy.com.

References

Smith, J.R. (2022). "Comparative Analysis of Inconel Alloys in Aerospace Applications." Journal of Aerospace Materials, 45(3), 278-295.

Johnson, M.K. & Lee, S.H. (2021). "Corrosion Behavior of Nickel-Based Superalloys in Marine Environments." Corrosion Science, 163, 108761.

Brown, A.C. (2023). "Heat Treatment Processes for Optimizing Inconel 718 Properties." Metallurgical and Materials Transactions A, 54(6), 1852-1867.

Garcia, E.L. et al. (2022). "Weldability and Fabrication Challenges of Inconel 625 in Chemical Processing Equipment." Welding Journal, 101(7), 205-218.

Thompson, R.D. (2021). "High-Temperature Performance of Nickel Superalloys in Gas Turbine Applications." International Journal of Turbomachinery, 12(4), 432-449.

Wilson, P.K. & Davis, T.L. (2023). "Mechanical Property Optimization of Inconel Alloys for Oil and Gas Industry Applications." Journal of Petroleum Engineering, 38(2), 156-173.

Learn about our latest products and discounts through SMS or email