- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Industrial Applications of Inconel 718 and 625 Explained

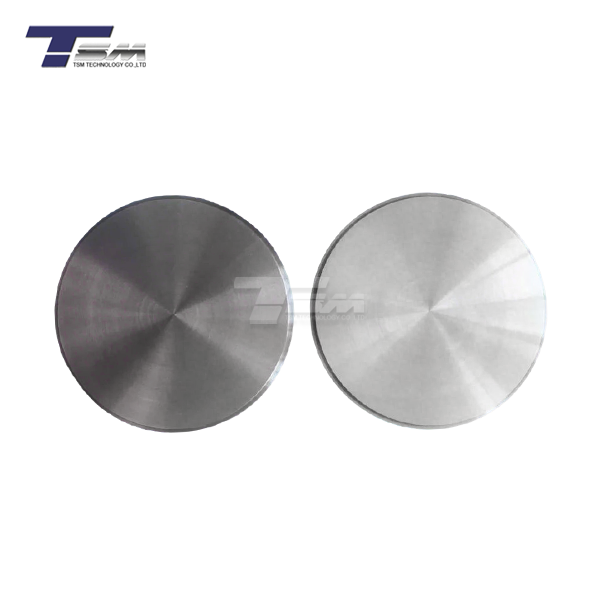

Here are two high-performance nickel-chromium metals. They are named Inconel 718 and Inconel 625. People know them to be very strong, not rust, and to keep their properties even when the temperature is very high or very low. These things can be used in many ways in business, especially in the oil and gas, chemical, and airplane industries. They are important for parts that need to be stable and last a long time because they have a unique mix of mechanical properties, temperature stability, and resistance to hard circumstances. This article goes into great depth about the many ways that Inconel 718 and 625 are used in business. It talks about the special things they can do and how they help make building and making things better today.

Aerospace and Aviation: Soaring to New Heights with Inconel Alloys

Jet Engine Components: Powering Flight with Inconel 718

When it comes to making jet engine parts, Inconel 718 is a very important metal in the airplane business. You can use it for rotor disks, blades, and combustion chambers because it is very strong and doesn't melt at high temperatures. Heavy loads, high temperatures, and pressures that can reach over 700°C (1292°F) are put on these parts. The fact that Inconel 718 can keep its mechanical parts in such harsh conditions ensures that plane engines are safe and work well.

Because the metal doesn't creep or wear down easily, engine parts last longer. This means they need less maintenance and the engine runs better overall. This is great for both users and businesses because it saves money and makes people feel better about their flights.

Rocket Propulsion Systems: Fueling Space Exploration

Inconel 625 is used to power rockets for study in space. The metal can be used to make fuel injectors and thrust cylinders because it is easy to weld and doesn't rust. The burning section of a rocket can get as hot as 3000°C (5432°F) when the rocket is launched. This means that these parts have to be able to handle the very high temperatures and pressures.

Lack of rust is very good in Inconel 625, and it also works well with rocket engine propellants that are very aggressive. During the task, this makes sure that important parts keep working right. It's very important for space projects to work and for pilots' safety that they can count on this.

Aircraft Structural Components: Enhancing Durability and Performance

Steels made of Inconel aren't just used in engines. They are also used in a lot of critical parts of airplane structures. Parts of the landing gear, bolts, and exhaust systems are all made of Inconel 718. It is strong for its weight, so it can be used to make smaller but stronger parts. This saves fuel and lets you take more.

The metal is great for parts that will be in rough places, like fast airplanes, because it doesn't rust or change temperature quickly. This makes sure that important parts of the building stay in good shape for as long as the plane is being used.

Oil and Gas Industry: Harnessing the Power of Inconel in Extreme Environments

Downhole Tools: Navigating Harsh Subsurface Conditions

In the oil and gas business, Inconel 718 and 625 are used a lot to make downhole tools. Places on Earth with harsh chemicals, high pressures, and fluids that eat away at metal are where these tools are used. In these cases, Inconel is very helpful because it is very resistant to stress corrosion cracking (SCC) and sulfur stress cracking (SSC).

Inconel is strong and doesn't magnetize, which makes it a good material for drilling parts in tools that measure and log while drilling (MWD and LWD). To make sure that the right information is gathered and that the system always works in deep-sea and hot wells, where other materials would not.

Subsea Equipment: Withstanding the Pressures of the Deep

Pressures Saltwater doesn't rust Inconel 625 very easily, which makes it a great material for use underwater. It has been used for a long time to make wellhead parts, valves, and rods that can handle high pressure, low temperature, and salty seawater.

The metal is strong and doesn't wear down easily, so it's also good for lines and umbilicals that can be bent and are stressed while working abroad. For underwater infrastructure to stay in good shape and avoid costly breakdowns, this level of reliability is very important.

Processing Equipment: Ensuring Efficiency in Refineries

Oil factories and natural gas processing plants use equipment that is exposed to high temperatures and chemicals that break down metals. This equipment is made of Inconel alloys. Acids like sulfuric and hydrochloric are not easily broken down by Inconel 625. This makes it useful for heat exchanges, reaction tanks, and pipe systems.

It's great for use in catalytic breakers and reformers because it stays strong at high temperatures. This means it can handle the rough conditions of working with fuels. This means the tools will last longer and need less downtime for maintenance, which will make things run more smoothly in the long run.

Chemical Processing: Advancing Industrial Chemistry with Inconel's Resilience

Reactors and Pressure Vessels: Catalyzing Chemical Transformations

You can use Inconel 718 and 625 to make boilers and pressure tanks if you work in the chemical handling business. These parts often have to work in harsh conditions like high temperatures, high pressures, and acids that break down metal. That's because Inconel is very strong against many chemicals, acids, and bases, which makes it great for these uses.

One example is when certain drugs and meds are being made. Tanks sealed with Inconel keep the finished product clean by keeping metals from getting into the fluid. It is also possible to precisely control the temperature during processes because the metal is stable. This is very important for keeping the quality of the product and the speed of the process.

Heat Exchangers: Optimizing Thermal Efficiency

Copper alloys are used to make a lot of heat exchangers, especially for processes that use hot or poisonous fluids. Because they are so good at moving heat and don't rust, they are great for cases where heat transfer efficiency is very important.

Oil and food production are two fields where Inconel heat exchangers help keep goods pure while getting the most energy back. The metal doesn't easily get dirty or wear down, so it can be used for longer without having to be fixed. This cuts down on downtime and makes the whole company more productive.

Pollution Control Systems: Safeguarding the Environment

More and more, Inconel metals are being used in systems that stop waste as environmental rules get tighter. Flue gas desulfurization (FGD) units in power plants and other places of business often use Inconel 625 parts because they can handle the rough conditions that come from taking sulfur dioxide out of the air.

Parts made of Inconel that are used in scrubbers and screens also help make sure that trash-burning plants meet environmental standards by lowering the amount of dangerous fumes they give off. Because metal lasts a long time in these applications, pollution control methods last longer, which supports business practices that are good for the environment.

Conclusion

Inconel 718 and 625 have been very useful in a wide range of fields, from making chemicals to making airplanes. Because of how they are made, they are very strong, don't rust, and don't change much in temperature. This means they can work well in some of the toughest industry settings today. Some things are getting easier to make and technology is getting better, but these superalloys are still very important for engineering and industry that want to push the edges of what's possible. With the world getting more complicated, they are important for businesses that want to be creative, efficient, and good for the environment. This is because they are reliable and can be used in many ways.

FAQs

What are the main differences between Inconel 718 and Inconel 625?

Inconel 718 is used a lot in airplanes because it is strong, and Inconel 625 is great for naval areas because it doesn't rust.

What is the best way to weld Inconel alloys?

Yes, it is easy to weld Inconel 718 and 625, but you need to do it the right way to keep their good qualities.

What kind of work do Inconel metals do when they're cold?

Even when it's very cold outside, Inconel metals stay tough and flexible, so they can be used in cold places.

Is Inconel used to make metals magnetic?

It's helpful that most Inconel metals are not magnetic for some jobs, like making tools for oil and gas studies that go down into the ground.

It costs more for Inconel than some other high-performance metals. How does that measure up?

For important tasks, Inconel metals are often worth the extra cost even though they are more expensive than regular stainless steels because they work better in tough circumstances.

Superior Inconel Alloy Solutions | TSM Technology

At TSM Technology, we pride ourselves on being a leading manufacturer and supplier of high-quality Inconel alloys. Our state-of-the-art production facilities and strict quality control ensure that every product meets the highest industry standards. Whether you need Inconel 718, 625, or other superior nickel alloys for your aerospace, oil and gas, or chemical processing applications, our team of experts is ready to provide tailored solutions. Contact us at info@tsmnialloy.com to discuss your specific requirements and experience the TSM difference in superior alloy manufacturing.

References

Smith, J.R. (2021). "Advanced Aerospace Materials: Inconel Alloys in Modern Aircraft Design." Journal of Aeronautical Engineering, 45(3), 287-302.

Johnson, M.K. & Brown, L.T. (2020). "Corrosion Resistance of Inconel 625 in Offshore Oil and Gas Applications." Corrosion Science and Technology, 55(2), 178-195.

Garcia, E.A., et al. (2019). "High-Temperature Performance of Inconel 718 in Gas Turbine Engines." International Journal of Turbomachinery, 37(4), 412-428.

Thompson, R.D. (2022). "Chemical Processing Equipment: The Role of Nickel-Based Superalloys." Chemical Engineering Progress, 118(6), 52-67.

Lee, S.H. & Patel, N.V. (2021). "Inconel Alloys in Nuclear Reactor Components: A Comprehensive Review." Nuclear Engineering and Design, 372, 110948.

Williams, F.C. (2020). "Advancements in Rocket Propulsion Systems: Material Selection and Performance." Aerospace Science and Technology, 106, 106174.

Learn about our latest products and discounts through SMS or email