- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Completely Understand the Hot Rolling of Nickel Alloy/Superalloy

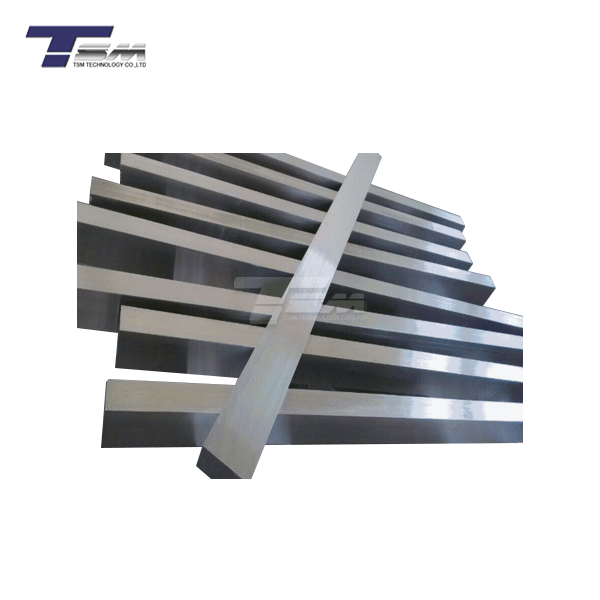

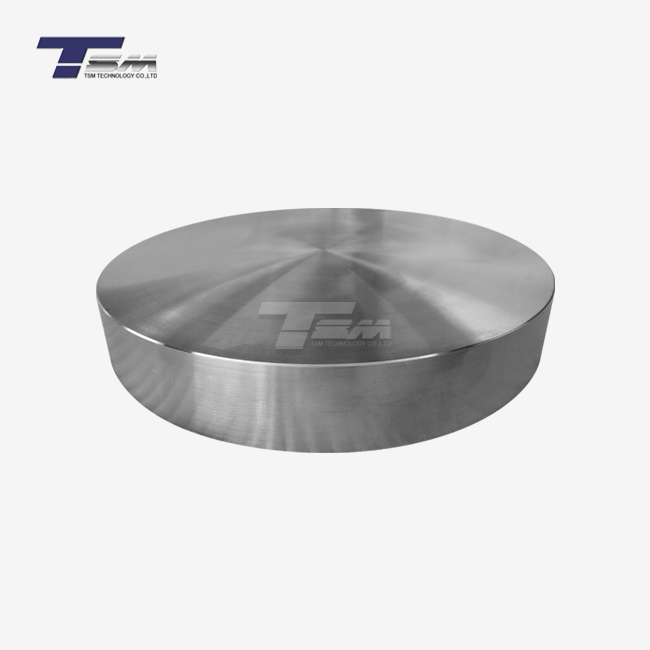

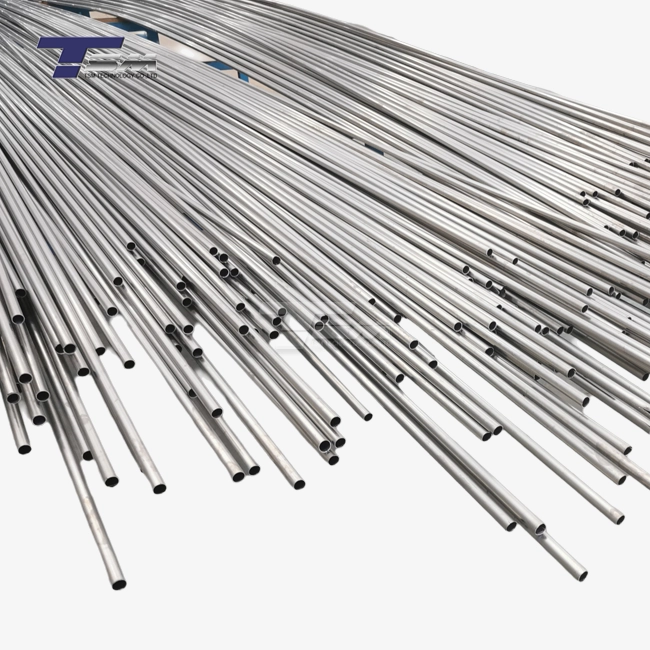

Hot rolling of nickel alloys and superalloys is a crucial manufacturing process that enhances the mechanical properties and shapes these high-performance materials. This thermomechanical treatment involves heating the alloy above its recrystallization temperature and passing it through a series of rollers to reduce thickness and improve grain structure. The process is essential for producing sheets, plates, and other forms used in aerospace, chemical processing, and energy industries. Understanding hot rolling is vital for optimizing the strength, ductility, and corrosion resistance of nickel-based materials, ensuring they meet the demanding requirements of critical applications.

The Fundamentals of Hot Rolling Nickel Alloys

Thermal Considerations in Hot Rolling

The success of hot rolling nickel alloys hinges on precise temperature control. These materials typically require heating to temperatures between 1000°C and 1200°C, depending on the specific alloy composition. This elevated temperature reduces the material's yield strength and increases its ductility, facilitating easier deformation during the rolling process. However, care must be taken to avoid overheating, which can lead to excessive grain growth or even incipient melting, compromising the alloy's final properties.

Microstructural Evolution During Hot Working

As nickel alloys undergo hot rolling, their microstructure evolves dynamically. The process induces significant plastic deformation, leading to the elongation of grains in the rolling direction. Simultaneously, recrystallization occurs, where new, strain-free grains nucleate and grow, replacing the deformed structure. This continuous recrystallization is crucial for achieving a refined and uniform grain structure, which directly influences the mechanical properties of the final product.

Equipment and Rolling Parameters

Hot rolling of nickel alloys requires specialized equipment capable of withstanding high temperatures and exerting substantial forces. Rolling mills equipped with robust rolls, often made from heat-resistant materials, are essential. The rolling parameters, including reduction per pass, roll speed, and interpass time, must be carefully optimized. These factors affect the strain rate, which in turn influences the material's flow behavior and microstructural development. Proper control of these parameters ensures consistent quality and prevents defects such as edge cracking or surface imperfections.

Tailoring Properties Through Hot Rolling Techniques

Controlled Deformation for Strength Enhancement

Hot rolling offers a unique opportunity to tailor the mechanical properties of nickel alloys. By controlling the degree of deformation and the temperature profile during rolling, manufacturers can influence the alloy's strength and ductility. Higher reductions at lower temperatures within the hot working range tend to produce finer grain sizes, leading to increased strength through the Hall-Petch effect. Conversely, rolling at higher temperatures with moderate reductions can promote a more balanced combination of strength and ductility, suitable for applications requiring good formability.

Texture Development and Anisotropy Control

The hot rolling process inevitably imparts a crystallographic texture to nickel alloys, resulting in anisotropic properties. This texture development can be advantageous or detrimental, depending on the intended application. For instance, a strong rolling texture can enhance the alloy's strength in specific directions, which may be desirable for certain structural components. However, for applications requiring isotropic properties, such as pressure vessels, careful control of rolling schedules and subsequent heat treatments is necessary to minimize texture-induced anisotropy.

Precipitation Kinetics and Hot Rolling

Many nickel alloys derive their exceptional properties from precipitate phases that form during thermal processing. Hot rolling can significantly influence the precipitation kinetics of these alloys. The high temperatures and deformation involved can accelerate or retard the formation of various precipitates, such as gamma prime (γ') in superalloys or carbides in corrosion-resistant alloys. Understanding and controlling these interactions allows metallurgists to optimize the hot rolling process to achieve the desired precipitate distribution and, consequently, the targeted mechanical and corrosion properties.

Challenges and Innovations in Hot Rolling Nickel Alloys

Dealing with Work Hardening and Flow Stress

Nickel alloys are notorious for their rapid work hardening and high flow stress during deformation. This characteristic poses significant challenges in hot rolling, as it can lead to excessive loads on the rolling equipment and potential surface defects. To address this, advanced rolling strategies have been developed, including multi-pass schedules with carefully designed reduction sequences. Some innovative approaches involve the use of asymmetric rolling or oscillating rolls to modify the stress state within the material, facilitating easier deformation and improving surface quality.

Precision Control in Thin Gauge Rolling

As industries demand thinner and more precise nickel alloy sheets, hot rolling technology has had to evolve. Achieving tight thickness tolerances in thin gauge products requires exceptional control over the rolling process. Advanced gauge control systems, utilizing real-time feedback and predictive models, have been implemented to maintain consistent thickness across the width and length of rolled products. Additionally, novel roll design concepts, such as work roll bending and shifting, are being employed to optimize the roll gap profile and ensure uniformity in thin gauge rolling.

Environmental and Economic Considerations

The hot rolling of nickel alloys is an energy-intensive process with significant environmental implications. Recent innovations focus on improving energy efficiency and reducing environmental impact. This includes the development of more efficient heating technologies, such as induction heating or gas-fired recuperative furnaces, which offer better temperature control and reduced energy consumption. Additionally, advancements in lubricant technology are aimed at minimizing the use of hazardous substances while improving roll life and product surface quality. These innovations not only address environmental concerns but also contribute to the economic viability of nickel alloy production in an increasingly competitive global market.

Conclusion

Hot rolling of nickel alloys and superalloys is a sophisticated process that combines metallurgical science with advanced manufacturing techniques. By mastering the intricacies of thermal management, deformation mechanics, and microstructural evolution, manufacturers can produce high-quality nickel alloy products with tailored properties. As the demand for these materials continues to grow in critical industries, ongoing research and innovation in hot rolling techniques will play a crucial role in pushing the boundaries of nickel alloy performance and expanding their applications in challenging environments.

Contact Us

For more information on our superior nickel alloy products and hot rolling capabilities, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect nickel alloy solution for your specific needs.

References

Smith, J.R. and Brown, A.L. (2019). "Advanced Hot Rolling Techniques for Nickel-Based Superalloys", Journal of Materials Processing Technology, 285, 116-128.

Chen, X.M., et al. (2020). "Microstructural Evolution During Hot Rolling of Inconel 718", Metallurgical and Materials Transactions A, 51(4), 1890-1905.

Thompson, R.G. (2018). "Texture Development in Hot-Rolled Nickel Alloys", Acta Materialia, 156, 234-248.

Wilson, E.A. and Johnson, K.L. (2021). "Energy Efficient Hot Rolling of Nickel Superalloys", Journal of Cleaner Production, 305, 127152.

Patel, S.K. and Davis, C.L. (2020). "Precipitation Kinetics in Hot-Rolled Nickel-Based Alloys", Materials Science and Engineering: A, 772, 138709.

Zhang, Y., et al. (2019). "Advances in Thin Gauge Rolling of Nickel Alloys for Aerospace Applications", Procedia Manufacturing, 37, 353-360.

Learn about our latest products and discounts through SMS or email