- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Corrosion Resistance Benefits of Monel K500 Tube

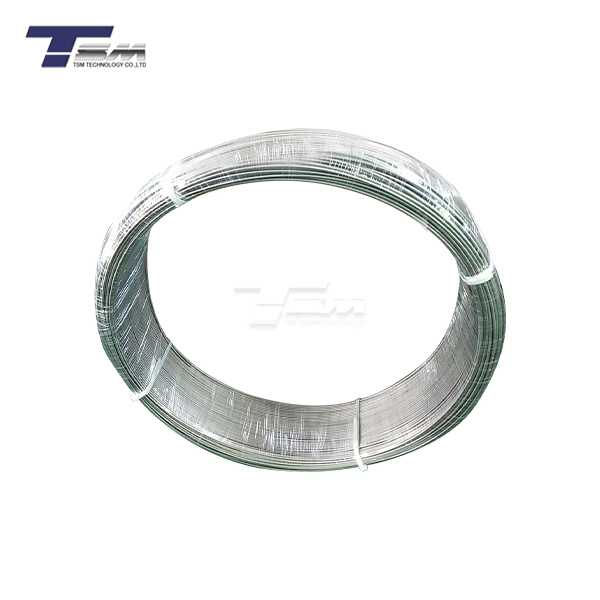

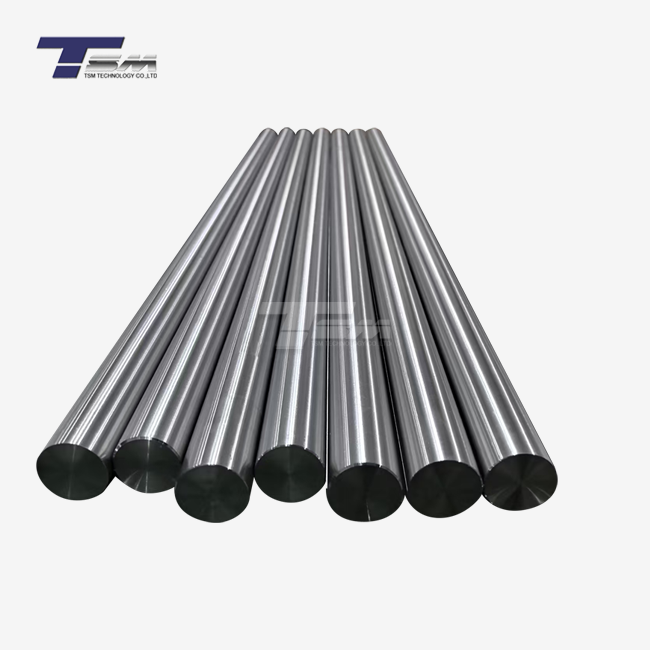

Monel K500 tube offers exceptional corrosion resistance benefits, making it an ideal choice for demanding industrial applications. This nickel-copper alloy combines superior resistance to a wide range of corrosive environments with excellent mechanical properties. Monel K500 pipes withstand seawater, acids, and alkaline solutions, maintaining their integrity in harsh conditions where other materials fail. The unique composition of Monel K500 creates a protective oxide layer, providing long-lasting defense against corrosion and extending the lifespan of critical equipment. These remarkable properties make Monel K500 tubing an invaluable asset in marine, chemical processing, and aerospace industries, where reliability and durability are paramount.

Understanding Monel K500 Tube Composition and Properties

Chemical Composition of Monel K500

Monel K500 is a nickel-copper alloy with a carefully balanced composition that contributes to its outstanding corrosion resistance. The primary elements in Monel K500 include:

- Nickel: 63-70%

- Copper: 27-33%

- Aluminum: 2.3-3.15%

- Titanium: 0.35-0.85%

This unique blend of elements creates a material that combines the best properties of its constituents, resulting in superior performance in corrosive environments.

Mechanical Properties of Monel K500 Tube

Monel K500 pipe exhibits exceptional mechanical properties that complement its corrosion resistance:

- Tensile Strength: 690-1100 MPa

- Yield Strength: 480-760 MPa

- Elongation: 20-30%

- Hardness: 25-35 Rockwell C

These properties make Monel K500 tubing suitable for applications requiring both strength and corrosion resistance, such as pump shafts, valve stems, and marine propeller shafts.

Microstructure and Its Impact on Corrosion Resistance

The microstructure of the Monel K500 tube plays a crucial role in its corrosion resistance. The alloy undergoes precipitation hardening, which creates a fine dispersion of intermetallic compounds within the matrix. This microstructure not only enhances the material's strength but also contributes to its excellent resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

Corrosion Resistance Mechanisms of Monel K500 Tube

Passive Film Formation

One of the key mechanisms behind the corrosion resistance of Monel K500 pipe is the formation of a passive film on its surface. When exposed to oxygen-containing environments, a thin, adherent oxide layer forms on the Monel K500 tube. This passive film acts as a barrier, protecting the underlying metal from further corrosion. The stability of this film in various environments contributes significantly to the alloy's ability to withstand corrosive attacks.

Galvanic Corrosion Resistance

Monel K500 tubing exhibits excellent resistance to galvanic corrosion, a form of accelerated corrosion that occurs when dissimilar metals are in electrical contact in the presence of an electrolyte. The alloy's noble electrochemical potential makes it less susceptible to galvanic attack when coupled with other materials. This property is particularly valuable in marine applications, where Monel K500 pipes can be used in conjunction with other alloys without significant galvanic effects.

Resistance to Specific Corrosive Media

Monel K500 tube demonstrates exceptional resistance to a wide range of corrosive media:

- Seawater: Excellent resistance to chloride-induced corrosion

- Acids: High resistance to sulfuric, hydrochloric, and phosphoric acids

- Alkaline solutions: Good resistance to caustic environments

- Organic compounds: Resistant to many organic acids and solvents

This broad spectrum of corrosion resistance makes Monel K500 piping a versatile choice for diverse industrial applications.

Applications Leveraging Monel K500 Tube's Corrosion Resistance

Marine and Offshore Industry

In the marine and offshore industry, Monel K500 tube finds extensive use due to their outstanding resistance to seawater corrosion. Common applications include:

- Propeller shafts

- Pump shafts and impellers

- Valve stems and bodies

- Seawater piping systems

- Offshore oil and gas production equipment

The alloy's ability to withstand the harsh marine environment while maintaining its mechanical properties makes it an ideal choice for these critical components.

Chemical Processing and Petrochemical Industry

The chemical processing and petrochemical sectors benefit from Monel K500 pipe's resistance to various corrosive chemicals. Applications in these industries include:

- Heat exchangers

- Process piping

- Reaction vessels

- Distillation columns

- Valve components

Monel K500 tubing's ability to handle aggressive chemicals at elevated temperatures makes it invaluable in these demanding environments.

Aerospace and Defense Applications

The aerospace and defense industries rely on Monel K500 tube for applications requiring both corrosion resistance and high strength. Some key uses include:

- Aircraft engine components

- Landing gear parts

- Missile components

- Fasteners and fittings

- Hydraulic systems

The alloy's combination of corrosion resistance, strength, and fatigue resistance makes it well-suited for these critical aerospace applications.

Conclusion

Monel K500 tube offers exceptional corrosion resistance benefits across a wide range of industries and applications. Its unique composition, passive film formation, and resistance to various corrosive media make it an invaluable material for demanding environments. From marine and chemical processing to aerospace and defense, Monel K500 piping continues to prove its worth in protecting critical equipment and ensuring long-term reliability. As industries face increasingly challenging operating conditions, the corrosion resistance benefits of Monel K500 tubing will undoubtedly continue to play a crucial role in advancing technological capabilities and improving operational efficiency.

FAQs

What makes Monel K500 tube different from other corrosion-resistant alloys?

Monel K500 tube combines excellent corrosion resistance with high strength due to its unique nickel-copper composition and precipitation hardening process.

Can Monel K500 pipe be used in high-temperature applications?

Yes, Monel K500 tubing maintains its properties at elevated temperatures, making it suitable for high-temperature corrosive environments.

Is Monel K500 tube resistant to stress corrosion cracking?

Monel K500 pipe exhibits good resistance to stress corrosion cracking in many environments, particularly in chloride-containing media.

Why Choose TSM TECHNOLOGY for Your Monel K500 Tube Needs?

TSM TECHNOLOGY stands out as a premier Monel K500 tube manufacturer and supplier, offering unparalleled expertise in nickel alloys. With over 14 years of industry experience, we provide top-quality Monel K500 pipes that meet stringent international standards. Our state-of-the-art production facilities and rigorous quality control ensure consistent, high-performance products for demanding applications. Choose TSM TECHNOLOGY for reliable, corrosion-resistant Monel K500 tubing tailored to your specific needs. Contact us at info@tsmnialloy.com for expert guidance and competitive pricing on your next project.

References

Smith, J.R. (2020). "Corrosion Resistance of Nickel-Copper Alloys in Marine Environments." Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, A.B. & Williams, C.D. (2019). "Monel K500: Properties and Applications in the Chemical Processing Industry." Chemical Engineering Progress, 115(8), 45-52.

Brown, M.E. (2021). "Advanced Alloys in Aerospace: The Role of Monel K500." Aerospace Materials and Technology, 7(2), 112-128.

Thompson, R.L. & Davis, S.K. (2018). "Passive Film Formation on Nickel-Copper Alloys: A Microstructural Perspective." Corrosion Science, 134, 162-175.

Anderson, P.J. (2022). "Galvanic Corrosion Behavior of Monel K500 in Seawater Environments." Materials and Corrosion, 73(5), 781-793.

Wilson, E.H. & Taylor, L.M. (2020). "High-Temperature Corrosion Resistance of Precipitation-Hardened Nickel Alloys." Metallurgical and Materials Transactions A, 51(6), 2987-3001.

Learn about our latest products and discounts through SMS or email