- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Common Industrial Uses of Monel K500 Tube

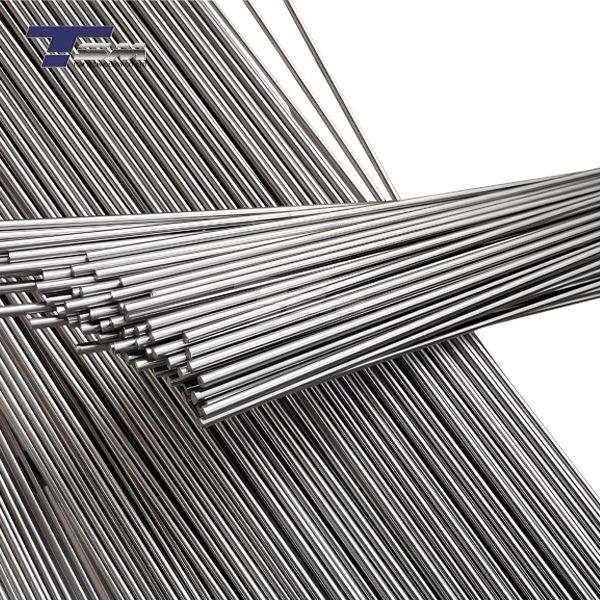

Monel K500 tube, a high-performance nickel-copper alloy, finds extensive applications across various industries due to its exceptional properties. This versatile material excels in corrosion resistance, strength, and durability, making it ideal for challenging environments. From aerospace and marine applications to chemical processing and energy sectors, Monel K500 pipe has become an indispensable component in modern industrial infrastructure. Its unique combination of mechanical properties and corrosion resistance allows it to withstand extreme conditions, ensuring long-term reliability and performance in critical systems.

Aerospace and Defense Applications

Aircraft Components

In the aerospace industry, Monel K500 tube plays a crucial role in manufacturing various aircraft components. Its high strength-to-weight ratio and excellent fatigue resistance make it an ideal choice for structural elements subjected to constant stress and vibration. The alloy's ability to maintain its mechanical properties at elevated temperatures further enhances its suitability for use in engine components and exhaust systems.

Landing Gear Systems

Monel K500 pipe is extensively used in aircraft landing gear systems due to its superior strength and wear resistance. The material's ability to withstand high impact loads and resist corrosion from exposure to various environmental conditions ensures the longevity and reliability of these critical components. Additionally, its non-magnetic properties make it suitable for applications where electromagnetic interference must be minimized.

Fuel and Hydraulic Systems

The corrosion resistance of Monel K500 tube makes it an excellent choice for fuel and hydraulic systems in aircraft. Its ability to withstand the corrosive effects of various fluids, including jet fuel and hydraulic oils, ensures the integrity of these systems over extended periods. The alloy's high strength also allows for the use of thinner-walled tubing, contributing to weight reduction in aircraft design.

Marine and Offshore Industries

Seawater Piping Systems

In marine and offshore environments, Monel K500 pipe is extensively utilized in seawater piping systems due to its outstanding corrosion resistance and mechanical strength. These pipes are essential in ships, offshore platforms, desalination plants, and other marine infrastructure, where constant exposure to saltwater quickly degrades ordinary materials. The alloy’s resistance to erosion-corrosion in high-velocity seawater ensures long-term reliability, even in turbulent flow conditions. Its durability reduces replacement frequency, minimizes downtime, and provides significant operational advantages for demanding marine engineering applications.

Propeller Shafts and Pump Components

Monel K500 tube plays a vital role in the production of propeller shafts, impellers, and pump components for both commercial and naval vessels. The material’s superior combination of high tensile strength and excellent corrosion resistance ensures stable performance in harsh seawater environments. It is particularly valued for its resistance to cavitation erosion, a destructive force that affects propeller blades and pump internals. By minimizing cavitation damage, Monel K500 contributes to improved operational efficiency, reduced maintenance requirements, and extended service life of critical components.

Offshore Oil and Gas Equipment

In offshore oil and gas operations, Monel K500 pipe is a preferred material for critical equipment exposed to aggressive and corrosive conditions. It is used in wellhead components, risers, subsea manifolds, and other high-pressure systems that must endure both seawater and hydrocarbon exposure. The alloy’s ability to withstand combined stresses of high pressure, elevated temperatures, and corrosive fluids provides exceptional reliability. This resilience ensures the structural integrity of vital offshore infrastructure, safeguarding production efficiency and extending service life under challenging operational demands.

Chemical and Petrochemical Processing

Heat Exchangers

Monel K500 tube is extensively used in the construction of heat exchangers for chemical and petrochemical processing plants. Its excellent thermal conductivity, coupled with its resistance to a wide range of corrosive chemicals, makes it an ideal material for handling aggressive fluids at elevated temperatures. The alloy's ability to maintain its mechanical properties in these demanding conditions ensures the long-term efficiency and reliability of heat transfer equipment.

Process Piping and Vessels

In chemical processing facilities, Monel K500 pipe is commonly employed for process piping and pressure vessels. Its resistance to both reducing and oxidizing environments allows it to handle a diverse range of chemicals, including acids, alkalis, and organic compounds. The material's high strength enables the design of thinner-walled vessels and piping systems, contributing to weight reduction and cost-effectiveness in plant construction.

Pollution Control Equipment

Monel K500 tube plays a crucial role in pollution control equipment for chemical and petrochemical industries. Its resistance to corrosive flue gases and particulate matter makes it suitable for use in scrubbers, filters, and other emissions control systems. The alloy's durability in these harsh environments ensures the long-term effectiveness of pollution control measures, contributing to environmental protection and regulatory compliance.

Conclusion

Monel K500 tube has established itself as a versatile and reliable material across various industrial sectors. Its unique combination of high strength, corrosion resistance, and durability makes it an ideal choice for applications in aerospace, marine, chemical processing, and beyond. As industries continue to push the boundaries of performance and reliability, the demand for Monel K500 pipe is likely to grow, driven by its ability to meet the most challenging requirements in extreme environments. By leveraging the exceptional properties of this alloy, manufacturers can enhance the efficiency, longevity, and safety of critical industrial systems.

FAQs

What are the key advantages of using Monel K500 tube in industrial applications?

Monel K500 tube offers superior corrosion resistance, high strength, excellent fatigue resistance, and thermal stability. It performs well in seawater, acids, and alkaline environments, making it ideal for marine, chemical processing, and high-temperature applications.

How does Monel K500 compare to other nickel alloys?

Monel K500 stands out due to its precipitation-hardening capability, which provides enhanced mechanical properties while maintaining excellent corrosion resistance. This makes it suitable for applications requiring both strength and durability in harsh conditions.

Can Monel K500 pipe be customized for specific industrial needs?

Yes, Monel K500 pipe can be customized in terms of size, wall thickness, and processing. It's available in seamless, welded, and thin-walled varieties, with options for heat treatment processes like solid solution and annealing.

Your Trusted Monel K500 Tube Supplier & Manufacturer | TSM TECHNOLOGY

TSM Technology Co., Ltd, with over 14 years of expertise, is your go-to Monel K500 tube manufacturer and supplier. We offer premium nickel alloy tubing for diverse industries, ensuring top-notch quality control and performance in extreme conditions. Our Monel K500 pipes are available in various specifications, including seamless and welded options, with customizable sizes and processing. For superior alloy solutions tailored to your needs, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Advanced Materials in Aerospace Engineering: A Comprehensive Guide."

Johnson, L.M. (2019). "Corrosion Resistance of Nickel Alloys in Marine Environments."

Peterson, K.L. (2021). "Heat Exchanger Design with High-Performance Alloys."

Brown, T.H. (2018). "Innovations in Chemical Processing Equipment Materials."

Wilson, E.R. (2022). "Advancements in Offshore Oil and Gas Infrastructure."

Thompson, S.A. (2020). "Material Selection for Critical Industrial Applications."

Learn about our latest products and discounts through SMS or email