- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Corrosion Resistance Tests for Incoloy 825 Round Bars

Corrosion resistance tests for Incoloy 825 round bars are crucial for validating the material's exceptional performance in harsh environments. These tests typically include immersion testing, electrochemical analysis, and stress corrosion cracking evaluations. By subjecting Incoloy 825 to simulated aggressive conditions, manufacturers can ensure its ability to withstand corrosive media, high temperatures, and mechanical stresses. The results of these tests demonstrate the alloy's superior resistance to pitting, crevice corrosion, and stress corrosion cracking, making it an ideal choice for critical applications in chemical processing, oil and gas, and marine industries.

Understanding Incoloy 825 Round Bars and Their Corrosion Resistance Properties

Composition and Characteristics of Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This unique composition gives the material its exceptional corrosion resistance properties. The high nickel content (38-46%) provides excellent resistance to chloride stress corrosion cracking, while chromium (19.5-23.5%) forms a protective oxide layer. Molybdenum (2.5-3.5%) enhances resistance to pitting and crevice corrosion, particularly in chloride-containing environments.

Applications Requiring High Corrosion Resistance

Incoloy 825 round bars find extensive use in industries where corrosion resistance is paramount. Some key applications include:

- Oil and gas extraction equipment

- Chemical processing vessels and piping

- Pollution control systems

- Nuclear fuel reprocessing plants

- Acid production and handling facilities

In these environments, the material's ability to withstand corrosive media, high temperatures, and mechanical stresses is critical for ensuring long-term reliability and safety.

Importance of Corrosion Resistance Testing

Corrosion resistance testing is essential for several reasons:

- Quality assurance: It verifies that the Incoloy 825 round bars meet industry standards and specifications.

- Performance prediction: Tests help predict how the material will behave in real-world applications.

- Material selection: Results guide engineers in choosing the right alloy for specific corrosive environments.

- Cost-effectiveness: Proper material selection based on test results can prevent costly failures and extend equipment life.

Types of Corrosion Resistance Tests for Incoloy 825 Round Bars

Immersion Testing

Immersion testing is a fundamental method for evaluating the corrosion resistance of Incoloy 825 round bars. In this test, samples are immersed in corrosive solutions that simulate real-world environments. Common test solutions include:

- Hydrochloric acid (HCl)

- Sulfuric acid (H2SO4)

- Sodium chloride (NaCl) solutions

- Mixed acid solutions

Samples are exposed for specified periods, often ranging from 24 hours to several weeks. After exposure, the samples are examined for weight loss, pitting, and other forms of corrosion. The corrosion rate is typically expressed in mils per year (mpy) or millimeters per year (mm/y).

Electrochemical Testing

Electrochemical testing provides a more rapid and detailed analysis of corrosion behavior. Common electrochemical tests include:

- Potentiodynamic polarization: This test measures the current-potential relationship of the material in a corrosive environment, providing information on corrosion rate and passivation behavior.

- Electrochemical Impedance Spectroscopy (EIS): EIS analyzes the corrosion mechanism and the protective nature of surface films.

- Cyclic potentiodynamic polarization: This method evaluates susceptibility to localized corrosion, such as pitting and crevice corrosion.

These tests offer insights into corrosion kinetics and mechanisms, allowing for a more comprehensive understanding of Incoloy 825's corrosion resistance.

Stress Corrosion Cracking Tests

Stress corrosion cracking (SCC) is a significant concern in many applications. Tests for SCC resistance in Incoloy 825 round bars include:

- U-bend tests: Samples are bent into a U-shape and exposed to corrosive media while under stress.

- Slow strain rate testing (SSRT): This method involves slowly straining a sample in a corrosive environment to evaluate its susceptibility to SCC.

- Constant load testing: Samples are subjected to a constant tensile load while exposed to a corrosive environment.

These tests help determine the material's resistance to cracking under combined mechanical and chemical stresses, which is crucial for applications in the oil and gas industry.

Interpreting Corrosion Resistance Test Results for Incoloy 825 Round Bars

Analyzing Corrosion Rates and Patterns

When interpreting corrosion test results for Incoloy 825 round bars, several factors are considered:

- Corrosion rate: Typically expressed in mils per year (mpy) or millimeters per year (mm/y), this indicates the material loss over time.

- Corrosion morphology: The type of corrosion (uniform, pitting, crevice) is assessed through visual and microscopic examination.

- Depth of attack: For localized corrosion, the maximum depth of pits or crevices is measured.

- Weight loss: The total material loss is calculated and compared to industry standards.

For Incoloy 825, exceptionally low corrosion rates (often <0.1 mpy) are expected in many environments, with minimal evidence of localized attack.

Comparing Results to Industry Standards

Test results are compared to established standards and specifications, such as:

- ASTM G31: Standard Guide for Laboratory Immersion Corrosion Testing of Metals

- NACE TM0169: Laboratory Corrosion Testing of Metals

- ASTM G48: Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys

Incoloy 825 typically outperforms many other alloys in these standardized tests, demonstrating its superior corrosion resistance.

Making Informed Material Selection Decisions

Based on test results, engineers can make informed decisions about using Incoloy 825 round bars in specific applications. Considerations include:

- Environmental compatibility: Ensuring the material's corrosion resistance matches the expected service conditions.

- Safety factors: Applying appropriate safety margins based on test results and application criticality.

- Cost-effectiveness: Balancing the higher initial cost of Incoloy 825 against its long-term performance benefits.

- Alternative materials: Comparing Incoloy 825's performance with other corrosion-resistant alloys for optimal selection.

By carefully analyzing test results, engineers can confidently specify Incoloy 825 round bars for applications requiring exceptional corrosion resistance.

Conclusion

Corrosion resistance tests for Incoloy 825 round bars are essential for validating the material's exceptional performance in harsh environments. Through immersion testing, electrochemical analysis, and stress corrosion cracking evaluations, manufacturers and end-users can ensure that Incoloy 825 meets the stringent requirements of critical applications. The superior results obtained from these tests underscore the alloy's ability to withstand aggressive media, high temperatures, and mechanical stresses. By understanding and interpreting these test results, engineers can make informed decisions, leading to improved reliability, safety, and cost-effectiveness in industries such as chemical processing, oil and gas, and marine applications.

FAQs

What makes Incoloy 825 round bars particularly resistant to corrosion?

Incoloy 825's unique composition of nickel, iron, chromium, molybdenum, copper, and titanium provides exceptional resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

How long do corrosion resistance tests typically take?

Test duration can vary from 24 hours for rapid electrochemical tests to several weeks for long-term immersion tests, depending on the specific test method and requirements.

Can Incoloy 825 round bars be used in seawater applications?

Yes, Incoloy 825 exhibits excellent resistance to seawater corrosion, making it suitable for marine and offshore applications.

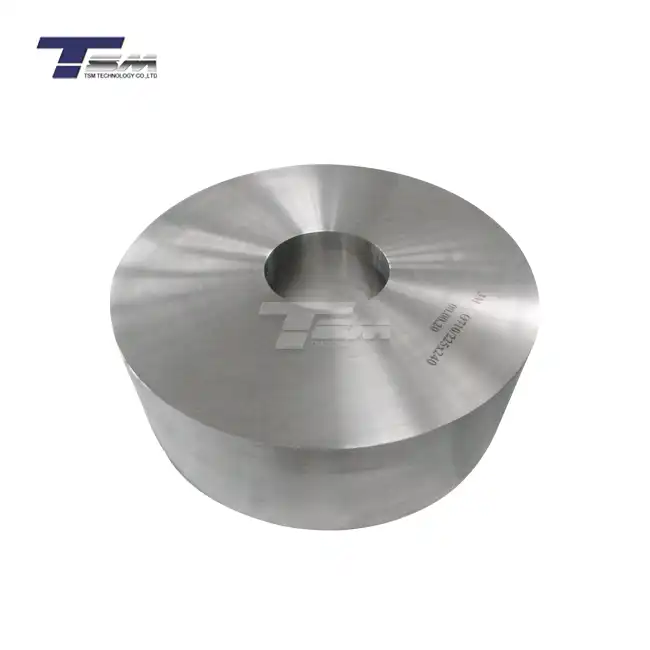

Why Choose TSM Technology for Your Incoloy 825 Round Bar Needs?

TSM Technology stands out as a premier manufacturer of high-quality Incoloy 825 round bars. With our state-of-the-art 3,200㎡ production facility in Shaanxi, China, featuring advanced equipment like vacuum arc furnaces and 2,500-ton forging presses, we ensure top-notch quality and consistency. Our ISO 9001 and AS9100 certifications guarantee adherence to international standards. Choose TSM for unparalleled expertise in Incoloy 825 round bars, available in various sizes and finishes. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "ASTM B425-20: Standard Specification for UNS N08825 and UNS N08221 Plate, Sheet, and Strip."

Special Metals Corporation. (2019). "Incoloy alloy 825 Technical Data Sheet."

Nace International. (2018). "Corrosion Testing in Natural Waters: Second Edition."

ASM International. (2017). "Corrosion: Fundamentals, Testing, and Protection."

Journal of Materials Engineering and Performance. (2020). "Corrosion Behavior of Incoloy 825 in Simulated Geothermal Environments."

Corrosion Science. (2019). "Electrochemical and XPS study of passive films on Incoloy 825 in acidic media."

Learn about our latest products and discounts through SMS or email