- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

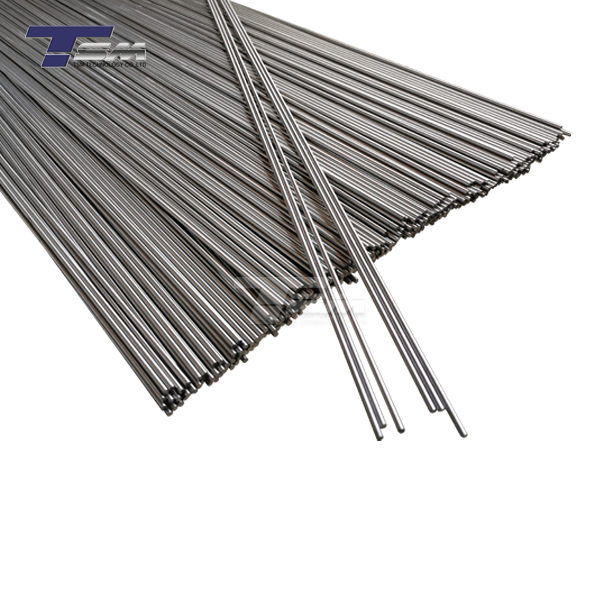

Incoloy 825 Round Bars for Heat Exchanger Tubes

Incoloy 825 round bars are the go-to material for heat exchanger tubes in demanding industrial applications. These high-performance nickel-iron-chromium alloys offer exceptional corrosion resistance and mechanical strength, making them ideal for chemical processing, oil and gas, and marine environments. With their unique combination of properties, Incoloy 825 round bars ensure long-lasting and efficient heat transfer in challenging conditions. This guide explores the benefits, applications, and key considerations when selecting Incoloy 825 round bars for heat exchanger tubes, helping you make informed decisions for your critical industrial projects.

Understanding Incoloy 825 Round Bars: Composition and Properties

Chemical Composition: The Secret Behind Its Performance

Incoloy 825 is a nickel-iron-chromium alloy with carefully balanced proportions of key elements. Its typical composition includes:

- 38-46% Nickel

- 19.5-23.5% Chromium

- 2.5-3.5% Molybdenum

- 0.6-1.2% Titanium

- Iron (balance)

This unique blend of elements contributes to the alloy's outstanding corrosion resistance and mechanical properties, making it suitable for heat exchanger tubes in aggressive environments.

Mechanical Properties: Strength and Durability

Incoloy 825 round bars exhibit impressive mechanical characteristics:

- Tensile Strength: 662 MPa (min)

- Yield Strength: 276 MPa (min)

- Elongation: 30% (min)

- Hardness: 79 HRB (max)

These properties ensure that heat exchanger tubes made from Incoloy 825 can withstand high pressures and temperatures while maintaining structural integrity over extended periods.

Corrosion Resistance: Withstanding Harsh Environments

The alloy's exceptional corrosion resistance is due to its high nickel and chromium content, along with the presence of molybdenum. This combination provides protection against:

- Pitting and crevice corrosion

- Stress corrosion cracking

- Sulfuric and phosphoric acid attacks

- Chloride-induced stress corrosion

As a result, Incoloy 825 round bars are ideal for heat exchanger tubes exposed to corrosive media in various industrial processes.

Applications of Incoloy 825 Round Bars in Heat Exchanger Tubes

Chemical Processing: Tackling Aggressive Chemicals

In the chemical processing industry, Incoloy 825 round bars are extensively used for heat exchanger tubes due to their resistance to a wide range of corrosive chemicals. They excel in applications involving:

- Sulfuric acid production

- Phosphoric acid handling

- Chlorine dioxide bleaching

- Pickling operations

The alloy's ability to withstand these aggressive environments ensures longer service life and reduced maintenance costs for heat exchangers in chemical plants.

Oil and Gas: Combating Sour Service Conditions

Incoloy 825 round bars are a preferred choice for heat exchanger tubes in the oil and gas industry, particularly in sour service conditions. They are commonly used in:

- Offshore platforms

- Refineries

- Gas processing plants

- Subsea equipment

The alloy's resistance to sulfide stress cracking and pitting corrosion makes it ideal for handling fluids containing hydrogen sulfide and chlorides, common in oil and gas operations.

Marine Applications: Battling Seawater Corrosion

In marine environments, Incoloy 825 round bars prove their worth in heat exchanger tubes exposed to seawater. They are frequently used in:

- Desalination plants

- Offshore platforms

- Marine propulsion systems

- Shipboard heat exchangers

The alloy's excellent resistance to chloride-induced pitting and crevice corrosion ensures reliable performance in these challenging marine applications.

Selecting and Specifying Incoloy 825 Round Bars for Heat Exchanger Tubes

Dimensional Considerations: Precision Matters

When selecting Incoloy 825 round bars for heat exchanger tubes, consider the following dimensional aspects:

- Outer diameter: Typically ranging from 3mm to 400mm

- Wall thickness: Determined by pressure and temperature requirements

- Length: Custom lengths available up to 6 meters

- Tolerances: Adhere to ASTM B425 or other relevant standards

Accurate dimensional specifications ensure proper fit and optimal heat transfer efficiency in your heat exchanger design.

Surface Finish Options: Enhancing Performance

The surface finish of Incoloy 825 round bars can significantly impact heat exchanger performance. Common finish options include:

- Bright finish: Smooth surface for improved flow characteristics

- Pickled (No. 1) finish: Enhanced corrosion resistance

- Polished (2B) finish: Superior smoothness for critical applications

- Custom finishes: Tailored to specific project requirements

Selecting the appropriate surface finish can optimize heat transfer efficiency and extend the service life of your heat exchanger tubes.

Quality Assurance: Meeting Industry Standards

To ensure the highest quality Incoloy 825 round bars for your heat exchanger tubes, look for materials that meet the following standards:

- ASTM B425: Standard specification for Ni-Fe-Cr-Mo-Cu alloy (UNS N08825) rod and bar

- ASME SB-425: Boiler and pressure vessel code specification

- NACE MR0175/ISO 15156: For sour service applications in oil and gas

- AMS 5766: Aerospace Material Specification for bars and forgings

Adherence to these standards ensures consistent quality and performance in your heat exchanger applications.

Conclusion

Incoloy 825 round bars are an excellent choice for heat exchanger tubes in demanding industrial environments. Their unique combination of corrosion resistance, mechanical strength, and versatility make them ideal for applications in chemical processing, oil and gas, and marine industries. By understanding the alloy's properties, applications, and selection criteria, you can make informed decisions when specifying Incoloy 825 round bars for your heat exchanger projects. Remember to consider dimensional requirements, surface finish options, and quality standards to ensure optimal performance and longevity of your heat exchange systems.

FAQs

What makes Incoloy 825 round bars suitable for heat exchanger tubes?

Incoloy 825 round bars offer exceptional corrosion resistance, high mechanical strength, and excellent performance in aggressive environments, making them ideal for heat exchanger tubes in chemical processing, oil and gas, and marine applications.

What are the key properties of Incoloy 825 round bars?

Incoloy 825 round bars have high nickel and chromium content, providing excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. They also offer good mechanical properties and can withstand high temperatures and pressures.

What surface finishes are available for Incoloy 825 round bars used in heat exchanger tubes?

Common surface finishes include bright finish, pickled (No. 1) finish, and polished (2B) finish. Custom finishes can also be provided to meet specific project requirements.

Choose TSM Technology for Your Incoloy 825 Round Bar Needs

TSM Technology is your trusted partner for high-quality Incoloy 825 round bars. With our state-of-the-art 3,200㎡ production facility in Shaanxi, China, we offer a wide range of sizes (3mm to 400mm diameter) and finishes to meet your heat exchanger tube requirements. Our ISO 9001 and AS9100 certifications ensure top-notch quality, while our 300 tons/month supply capacity guarantees timely deliveries. Experience our exceptional service and product quality - contact us at info@tsmnialloy.com for a free sample or to discuss your custom needs.

References

ASTM International. (2020). ASTM B425-20 Standard Specification for Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825) Rod and Bar. West Conshohocken, PA: ASTM International.

Special Metals Corporation. (2019). INCOLOY alloy 825 Technical Data Sheet. New Hartford, NY: Special Metals Corporation.

Sridhar, N., & Tormoen, G. (2018). Corrosion of Nickel-Base Alloys in Oil and Gas Production Environments. In R. Winston Revie (Ed.), Oil and Gas Corrosion Prevention (pp. 219-246). Gulf Professional Publishing.

Cramer, S. D., & Covino, B. S. (Eds.). (2003). ASM Handbook, Volume 13A: Corrosion: Fundamentals, Testing, and Protection. ASM International.

Herda, W. R., & Starr, F. (2012). Heat Exchanger Tube Failure: Theory and Practice. CRC Press.

Schweitzer, P. A. (2010). Fundamentals of Corrosion: Mechanisms, Causes, and Preventative Methods. CRC Press.

Learn about our latest products and discounts through SMS or email