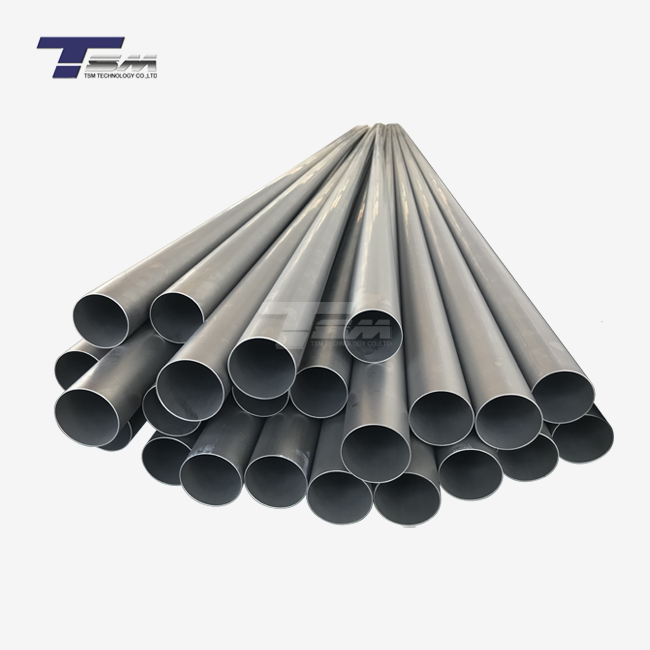

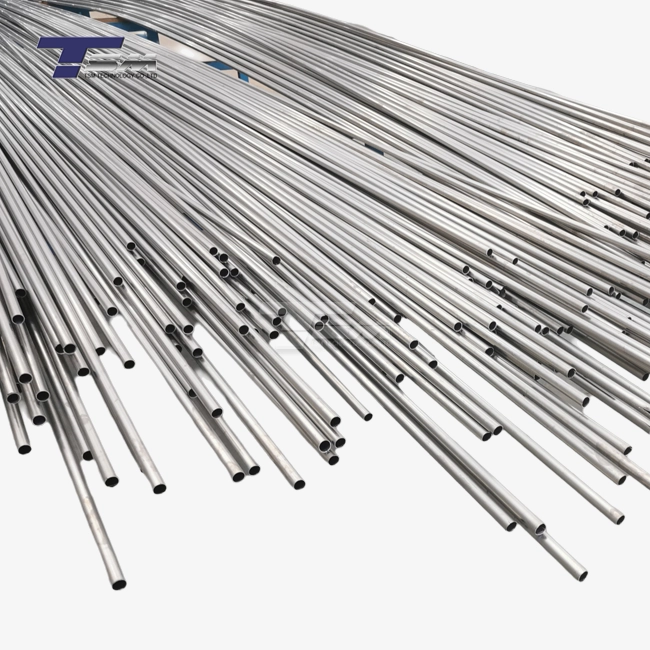

Understanding Incoloy 825 Tube Specifications

Chemical Composition and Properties

Incoloy 825, also known as UNS N08825 or Alloy 825, is a nickel-iron-chromium alloy with excellent resistance to corrosion in various aggressive environments. Its unique chemical composition typically includes:

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 38 – 46 |

| Chromium (Cr) | 19.5 – 23.5 |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Titanium (Ti) | 0.6 – 1.2 |

| Copper (Cu) | 1.5 – 3.0 |

| Iron (Fe, balance) | ~22 |

This carefully balanced composition imparts Incoloy 825 with exceptional properties, including:

- Outstanding resistance to pitting and crevice corrosion

- Excellent resistance to stress corrosion cracking

- High strength and toughness across a wide temperature range

- Good weldability and formability

Manufacturing Process

The production of Incoloy 825 tubes involves several critical steps:

- Melting and alloying of raw materials

- Ingot casting or continuous casting

- Hot working (forging or rolling) to achieve the desired shape

- Cold working to refine grain structure and improve mechanical properties

- Heat treatment to optimize microstructure and properties

- Tube forming through processes like extrusion or pilgering

- Final sizing and finishing operations

Each stage of the manufacturing process requires precise control to ensure the dimensional accuracy and material integrity of the finished Incoloy 825 tubes.

Industry Standards and Specifications

Incoloy 825 tubes are manufactured to meet various international standards and specifications, including:

- ASTM B163: Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- ASTM B423: Standard Specification for Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and UNS N08221) Seamless Pipe and Tube

- ASME SB-163: Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- ASME SB-423: Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and UNS N08221) Seamless Pipe and Tube

These standards provide guidelines for chemical composition, mechanical properties, and dimensional tolerances that manufacturers must adhere to when producing Incoloy 825 tubes.

Dimensional Inspection Techniques for Incoloy 825 Tubes

Visual Inspection

Visual inspection is the first line of defense in ensuring the quality of Incoloy 825 tubes. Trained inspectors examine the tubes for visible defects such as:

- Surface imperfections (scratches, dents, or pits)

- Straightness deviations

- Obvious dimensional inconsistencies

- Discoloration or oxidation

While visual inspection is not sufficient for precise dimensional verification, it serves as a crucial initial screening process to identify gross defects or nonconformities.

Mechanical Measurement Tools

Various mechanical measurement tools are employed for precise dimensional inspection of Incoloy 825 pipe:

- Micrometers: Used for measuring outer diameter and wall thickness with high accuracy

- Calipers: Versatile tools for measuring outer diameter, length, and other external dimensions

- Bore gauges: Utilized for measuring internal diameter of tubes

- Straight edges and feeler gauges: Used to check straightness and roundness

- Tape measures: Employed for measuring overall length of tubes

These tools provide direct measurements and are often used in conjunction with more advanced inspection techniques for comprehensive dimensional verification.

Advanced Measurement Technologies

Modern inspection processes for Incoloy 825 tubes incorporate advanced measurement technologies for enhanced accuracy and efficiency:

- Coordinate Measuring Machines (CMM): Provide highly accurate 3D measurements of tube dimensions and geometry

- Laser scanning systems: Offer rapid, non-contact measurement of tube profiles and surface characteristics

- Ultrasonic thickness gauges: Enable precise measurement of wall thickness without damaging the tube

- Optical comparators: Allow for quick visual comparison of tube profiles against standard templates

- Eddy current testing: Detects surface and near-surface defects that may affect dimensional integrity

These advanced technologies enable manufacturers to perform comprehensive dimensional inspections with high precision and repeatability, ensuring the consistent quality of Incoloy 825 tubes.

Tolerances and Quality Control for Incoloy 825 Tubes

Dimensional Tolerance Standards

Dimensional tolerances for Incoloy 825 tubes are typically specified in accordance with industry standards such as ASTM B163 and ASTM B423. These standards define acceptable ranges for key dimensions, including:

- Outer Diameter (OD): Typically ±0.004 inch or ±1% of the specified OD, whichever is less

- Wall Thickness: Usually +15% / -12.5% of the nominal thickness

- Length: Often ±1/8 inch for cut lengths up to 24 inches, with increasing tolerances for longer tubes

- Straightness: Generally limited to 0.030 inch per 3 feet of length

- Ovality: Typically restricted to 2% of the specified OD

It's important to note that these tolerances may vary depending on the specific application and customer requirements. Some applications may demand tighter tolerances to ensure optimal performance and reliability.

Quality Control Procedures

Ensuring the dimensional accuracy of Incoloy 825 pipe involves rigorous quality control procedures:

- Incoming material inspection: Verifying the quality and dimensions of raw materials

- In-process inspections: Conducting dimensional checks at various stages of tube production

- Final inspection: Comprehensive measurement of finished tubes against specified tolerances

- Sampling plans: Implementing statistical sampling methods to ensure consistent quality across production lots

- Non-conformity management: Identifying, segregating, and addressing any tubes that fall outside specified tolerances

- Documentation and traceability: Maintaining detailed records of inspection results and material certifications

These procedures help manufacturers maintain tight control over the dimensional accuracy of Incoloy 825 tubes throughout the production process.

Impact of Tolerances on Performance

Adherence to dimensional tolerances is critical for the performance of Incoloy 825 tubes in various applications:

- Heat exchangers: Precise dimensions ensure optimal heat transfer efficiency and proper fit within tube sheets

- Pressure vessels: Accurate wall thickness is crucial for withstanding design pressures and ensuring safety

- Chemical processing equipment: Consistent dimensions contribute to reliable flow characteristics and corrosion resistance

- Oil and gas applications: Tight tolerances help maintain integrity in harsh environments and high-pressure conditions

Maintaining strict dimensional tolerances not only ensures the functionality of Incoloy 825 tubes but also contributes to the overall reliability and longevity of the systems in which they are installed.

Conclusion

Dimensional inspection and adherence to tolerances are paramount in the production of high-quality Incoloy 825 tubes. These processes ensure that the tubes meet the stringent requirements of various industries, from chemical processing to oil and gas exploration. By employing a combination of visual inspection, mechanical measurements, and advanced technologies, manufacturers can guarantee the dimensional accuracy and consistency of Incoloy 825 tubes. Strict quality control procedures and compliance with industry standards further reinforce the reliability of these critical components. As industries continue to demand higher performance and longer service life from their materials, the importance of precise dimensional control in Incoloy 825 tube production will only increase, driving ongoing innovations in inspection techniques and manufacturing processes.

FAQs

What are the key dimensions inspected in Incoloy 825 tubes?

The primary dimensions inspected include outer diameter, wall thickness, length, straightness, and ovality.

How often should dimensional inspections be performed during the manufacturing process?

Inspections are typically conducted at multiple stages: incoming material inspection, in-process checks, and final inspection of finished tubes.

Can tighter tolerances be achieved for special applications?

Yes, manufacturers can often accommodate tighter tolerances for specific applications, though this may impact production costs and lead times.

How do dimensional tolerances affect the performance of Incoloy 825 tubes?

Proper tolerances ensure optimal fit, functionality, and reliability in applications such as heat exchangers, pressure vessels, and chemical processing equipment.

Expert Incoloy 825 Tube Inspection and Supply | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality Incoloy 825 tubes with rigorous dimensional inspection and precise tolerances. Our state-of-the-art manufacturing facility and experienced team ensure that every tube meets or exceeds industry standards. As a leading Incoloy 825 tube supplier and manufacturer, we offer customized solutions to meet your specific requirements. For expert assistance and premium Incoloy 825 products, contact us at info@tsmnialloy.com.

References

ASTM International. (2020). ASTM B163-20: Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes. West Conshohocken, PA: ASTM International.

Special Metals Corporation. (2019). Incoloy alloy 825 Technical Data Sheet. Huntington, WV: Special Metals Corporation.

American Society of Mechanical Engineers. (2019). ASME Boiler and Pressure Vessel Code, Section II: Materials. New York, NY: ASME.

Nace International. (2018). Corrosion of Nickel-Base Alloys. Houston, TX: Nace International.

ASM International. (2017). ASM Handbook, Volume 2A: Aluminum Science and Technology. Materials Park, OH: ASM International.

TWI Ltd. (2016). Welding of Nickel Alloys - Part 1. Cambridge, UK: TWI Ltd.