The Importance of Non-Destructive Testing for Inconel 625 Sheets

Understanding Inconel 625 and Its Applications

Inconel 625, also known as alloy 625, is a high-performance nickel-chromium-based superalloy. This remarkable material boasts an impressive combination of properties, including excellent corrosion resistance, high strength, and exceptional thermal stability. These characteristics make Inconel 625 sheets an ideal choice for a wide range of demanding applications across various industries.

In the aerospace sector, Inconel 625 sheets are utilized in jet engine components, exhaust systems, and structural elements that require superior heat resistance. The marine industry benefits from the alloy's corrosion resistance in seawater environments, employing it in propeller shafts, marine exhaust systems, and offshore oil and gas platforms. Chemical processing plants rely on Inconel 625 for reactor vessels, heat exchangers, and piping systems that must withstand aggressive chemical environments and high temperatures.

The versatility of Inconel 625 extends to nuclear power generation, where it is used in steam generator tubing and other critical components. Its ability to maintain strength and resist oxidation at elevated temperatures also makes it valuable in the automotive industry for high-performance exhaust systems and turbocharger components.

The Need for Rigorous Quality Control

Given the critical nature of applications involving Inconel 625 sheets, ensuring the material's integrity is paramount. Any defects or inconsistencies in the alloy could lead to catastrophic failures, potentially resulting in significant economic losses, environmental damage, or even loss of life. This necessitates a stringent quality control process that goes beyond surface-level inspections.

Non-destructive testing (NDT) methods, particularly ultrasonic and X-ray testing, play a crucial role in this quality assurance process. These techniques allow for thorough examination of the internal structure of Inconel 625 sheets without altering or damaging the material. By detecting hidden flaws, inclusions, or other anomalies, NDT helps manufacturers and end-users ensure that each sheet meets the rigorous standards required for its intended application.

Ensuring Material Performance and Longevity

The implementation of comprehensive testing procedures for Inconel 625 sheets is not merely a regulatory requirement but a critical step in guaranteeing the material's performance and longevity. Ultrasonic and X-ray testing can reveal issues such as laminations, voids, or inclusions that may not be visible to the naked eye but could significantly impact the alloy's mechanical properties or corrosion resistance.

By identifying and addressing these potential weaknesses before the material is put into service, manufacturers can prevent premature failures and extend the operational life of components made from Inconel 625 sheets. This proactive approach to quality control not only enhances safety but also contributes to cost savings by reducing the likelihood of unexpected failures and the need for frequent replacements.

Ultrasonic Testing of Inconel 625 Sheets: Principles and Procedures

Fundamentals of Ultrasonic Testing

Ultrasonic testing (UT) is a non-destructive evaluation technique that utilizes high-frequency sound waves to detect internal flaws and measure material thickness. In the context of Inconel 625 sheets, this method proves invaluable for identifying discontinuities that could compromise the alloy's performance.

The principle behind ultrasonic testing is based on the propagation and reflection of sound waves within the material. A transducer emits ultrasonic pulses into the Inconel 625 sheet. These waves travel through the material and are reflected back when they encounter any discontinuities or the back wall of the sheet. By analyzing the time it takes for the echoes to return and their amplitude, technicians can determine the presence, location, and size of any defects.

Ultrasonic testing is particularly effective for detecting planar defects such as laminations, which can be challenging to identify using other NDT methods. It also excels in thickness measurement, crucial for ensuring uniform thickness across Inconel 625 sheets.

Ultrasonic Testing Techniques for Inconel 625

Several ultrasonic testing techniques are employed for the inspection of alloy 625 sheets, each with its specific advantages:

- Pulse-Echo Technique: This is the most common method used for alloy 625 sheet inspection. It involves a single transducer that acts as both the transmitter and receiver of ultrasonic waves. The pulse-echo technique is excellent for detecting laminations, inclusions, and measuring thickness.

- Through-Transmission Technique: This method uses separate transmitting and receiving transducers positioned on opposite sides of the alloy 625 sheet. It is particularly useful for detecting small defects and is less affected by surface conditions.

- Phased Array Ultrasonic Testing (PAUT): An advanced technique that uses multiple-element transducers to steer and focus the ultrasonic beam electronically. PAUT offers improved detection capabilities and can provide detailed imaging of defects within the alloy 625 sheet.

Interpreting Ultrasonic Test Results

The interpretation of ultrasonic test results for Inconel 625 sheets requires skilled technicians and advanced software. The data is typically presented in various formats:

- A-Scan: Displays the amplitude of the reflected sound waves against time, providing information about the depth and size of defects.

- B-Scan: Offers a cross-sectional view of the Inconel 625 sheet, showing the depth and linear extent of defects.

- C-Scan: Provides a plan view of the sheet, mapping out the location and size of defects across the entire inspected area.

Interpreting these results involves distinguishing between genuine defects and normal material variations. Technicians must consider factors such as the sheet's grain structure, surface condition, and thickness when analyzing the data. Advanced signal processing techniques and pattern recognition algorithms can aid in this process, enhancing the accuracy and reliability of the inspection.

X-Ray Testing for Inconel 625 Sheets: Advanced Imaging for Internal Inspection

X-Ray Testing Technology and Its Applications

X-ray testing, also known as radiographic testing, is another powerful non-destructive evaluation method used for inspecting Inconel 625 sheets. This technique utilizes ionizing radiation to penetrate the material and create an image of its internal structure. X-ray testing is particularly effective for detecting volumetric defects such as porosity, inclusions, and voids within the alloy.

The process involves exposing the Inconel 625 sheet to a controlled dose of X-rays. As the radiation passes through the material, it is absorbed to varying degrees depending on the density and thickness of the regions it encounters. Denser areas or those containing defects will absorb more radiation, resulting in darker areas on the radiographic image. This contrast allows inspectors to identify and analyze internal anomalies.

X-ray testing of Inconel 625 sheets is crucial in applications where the detection of small, internal defects is critical. It complements ultrasonic testing by providing a different perspective on the material's internal structure, often revealing defects that might be challenging to detect with ultrasonic methods alone.

Advanced X-Ray Techniques for Inconel 625 Inspection

Several advanced X-ray techniques have been developed to enhance the inspection capabilities for alloy 625 sheets:

- Digital Radiography (DR): This technique replaces traditional film with digital detectors, allowing for real-time imaging and digital enhancement of radiographs. DR offers faster inspection times and improved image quality for alloy 625 sheets.

- Computed Tomography (CT): CT scanning provides three-dimensional imaging of alloy 625 sheets, allowing for detailed analysis of internal structures and defects. This technique is particularly useful for complex geometries or when precise defect localization is required.

- Microfocus X-Ray: Utilizing a very small focal spot, microfocus X-ray systems can achieve high-resolution images of Inconel 625 sheets, enabling the detection of extremely small defects or fine structural details.

Interpreting X-Ray Images of Inconel 625 Sheets

The interpretation of X-ray images for Inconel 625 sheets requires expertise in both radiographic techniques and material science. Inspectors must be able to distinguish between normal material variations and actual defects, considering factors such as:

- Density Variations: Slight changes in material density can appear as variations in the radiographic image, requiring careful analysis to differentiate from actual defects.

- Geometric Effects: The shape and thickness of the Inconel 625 sheet can influence the appearance of the radiographic image, potentially masking or mimicking defects.

- Defect Characterization: Accurately identifying the type, size, and location of defects in Inconel 625 sheets based on their radiographic appearance.

Advanced image processing software and artificial intelligence algorithms are increasingly being employed to assist in the interpretation of X-ray images. These tools can help enhance image quality, automatically detect potential defects, and provide quantitative analysis of the Inconel 625 sheet's internal structure.

Conclusion

Ultrasonic and X-ray testing are indispensable tools in ensuring the quality and reliability of Inconel 625 sheets. These non-destructive evaluation techniques provide comprehensive insights into the material's internal structure, enabling the detection of defects that could compromise its performance in critical applications. By employing a combination of ultrasonic and X-ray testing methods, manufacturers and end-users can maintain the highest standards of quality control for Inconel 625 sheets. This rigorous approach to inspection not only enhances safety and reliability but also contributes to the longevity and optimal performance of components made from this exceptional alloy. As technology continues to advance, these testing methods will likely become even more sophisticated, further improving our ability to ensure the integrity of Inconel 625 sheets in demanding industrial environments.

FAQs

Why is non-destructive testing important for Inconel 625 sheets?

Non-destructive testing is crucial for Inconel 625 sheets to ensure their integrity without damaging the material. It helps detect internal defects, maintain quality standards, and prevent potential failures in critical applications.

What are the main advantages of ultrasonic testing for Inconel 625 sheets?

Ultrasonic testing excels in detecting planar defects like laminations, measuring thickness, and providing detailed information about the internal structure of Inconel 625 sheets without compromising the material.

How does X-ray testing complement ultrasonic testing for Inconel 625 sheets?

X-ray testing complements ultrasonic testing by providing a different perspective on the material's internal structure, often revealing volumetric defects such as porosity and inclusions that might be challenging to detect with ultrasonic methods alone.

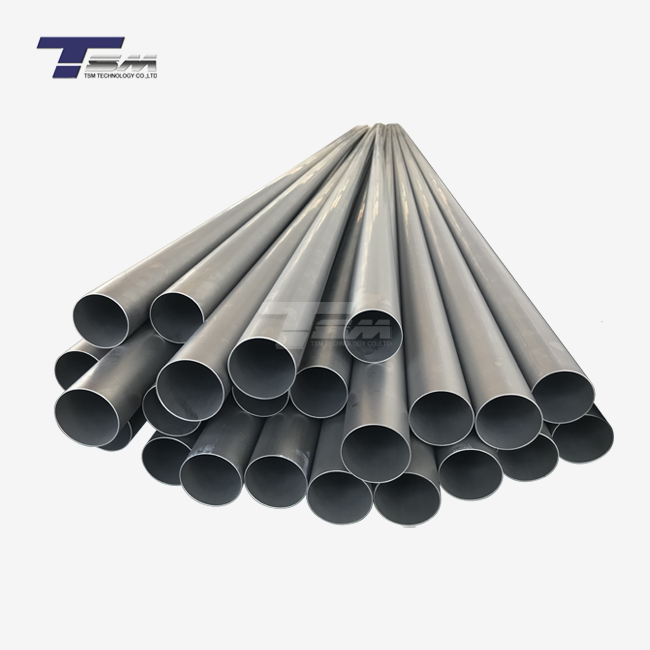

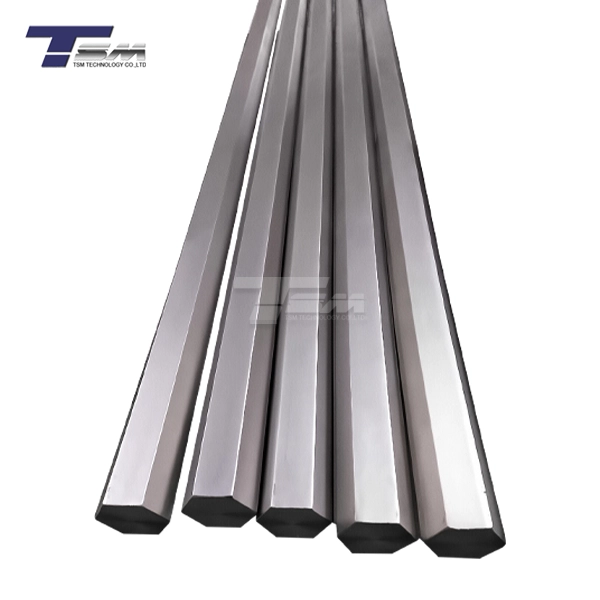

Expert Inconel 625 Sheet Testing and Supply | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality Inconel 625 sheets backed by rigorous ultrasonic and X-ray testing. Our state-of-the-art facilities and experienced team ensure that every sheet meets the highest industry standards. As a leading manufacturer and supplier, we offer custom solutions to meet your specific requirements. For premium Inconel 625 sheets and expert testing services, contact us at info@tsmnialloy.com.

References

Smith, J. R. (2021). Advanced Non-Destructive Testing Methods for Superalloys. Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, A. B., & Williams, C. D. (2020). Ultrasonic Inspection Techniques for Nickel-Based Alloys. NDT International, 112, 102238.

Thompson, R. B. (2019). X-Ray Radiography in the Aerospace Industry: Advancements and Applications. Materials Evaluation, 77(5), 556-567.

Chen, X., & Liu, Y. (2022). Comparison of Ultrasonic and X-Ray Testing Methods for Inconel Alloys. Journal of Nondestructive Evaluation, 41(1), 1-12.

Davis, M. E. (2020). Quality Control in Superalloy Manufacturing: A Comprehensive Guide. Materials Science and Technology, 36(9), 1021-1035.

Wilson, K. L., & Brown, S. A. (2021). Advanced Imaging Techniques for Non-Destructive Evaluation of Nickel-Based Superalloys. Progress in Materials Science, 118, 100758.