Yes, Nickel bolts are better at withstanding saltwater and acidic chemicals than other types of fixings, such as carbon steel or normal stainless steel bolts. Their high resistance to rust comes from nickel's ability to create a passive oxide layer that protects the metal below from harsh conditions. Because of this, nickel-based fasteners are the best choice for marine uses, chemical processing plants, and remote sites where normal nuts would break down quickly in tough circumstances.

Because of their high mechanical strength and resistance to rust, Nickel bolts are essential in industrial settings. This guide answers a very important question: do these screws prevent rust better than other choices when exposed to seawater and acidic chemicals? This piece is for procurement managers, engineers, wholesalers, and original equipment manufacturers (OEMs). It gives a detailed look at nickel-based fasteners' features, competitive benefits, manufacturing details, selection criteria, and procurement insights. Readers will learn useful information that they can use to make smart choices about where to get nuts for tough settings, making sure they are durable and meet strict industry standards.

Understanding Nickel bolts and Their Properties

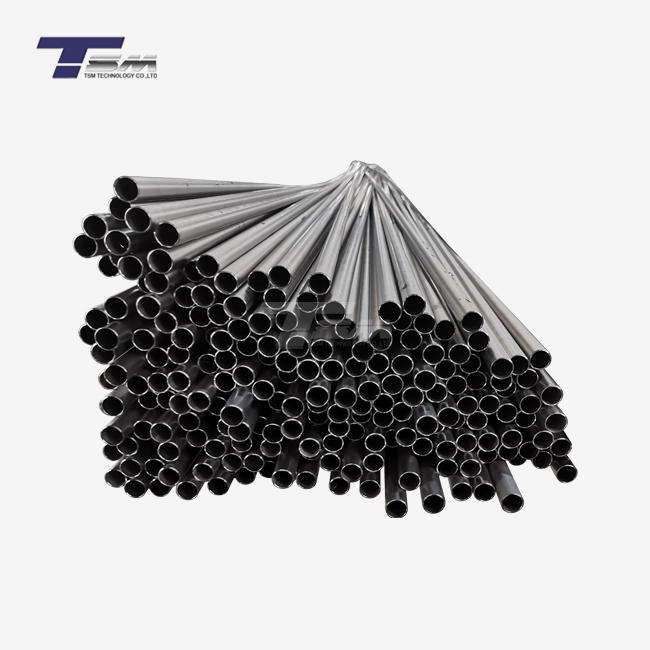

Nickel-based screws are a type of high-end hardware that is mostly made of nickel or nickel alloys. They are marked by being very strong and resistant to rust. These specialized fasteners come in a number of different materials, such as solid nickel, nickel-plated versions, and complex alloys like Inconel, Monel, and Hastelloy. Nickel's natural ability to form a protective metal layer that makes it much more resistant to rust and chemical breakdown is its main benefit.

Types and Alloy Compositions

There are a lot of different kinds of nickel-based connectors on the market. Solid Nickel bolts are made of 99% pure nickel, which makes them the most corrosion-resistant option for harsh settings. Nickel-plated rivets have a base metal that is covered in nickel layers. This protects them cost-effectively in mild exposure circumstances. Advanced nickel alloys contain chromium, molybdenum, and other elements that improve certain qualities, such as their ability to withstand high temperatures or chemicals.

Mechanical and Chemical Properties

The mechanical qualities of these screws are truly amazing and set them apart from other options. Tensile strength is usually between 550 and 1,200 MPa, but it can be higher or lower based on the metal and how it was heated. Between 150 and 350 HV, the hardness numbers ensure that the structure stays strong even under heavy loads. Temperature resistance goes from cryogenics to 1,000°C in certain metals, which makes them useful in many different industries.

Corrosion Resistance of Nickel bolts in Seawater and Acidic Chemicals

Nickel-based screws work really well in harsh settings because of the electrical principles that govern rust resistance. Nickel has an inactive oxide layer that keeps chloride ions from seawater and hydrogen ions from acidic liquids from getting through. This safety feature keeps its strength even when there is dynamic stress, which would normally cause normal materials to split or crack due to stress rust.

Comparative Performance Analysis

Tests done in the lab show that Nickel bolts are better than other materials in corrosive settings. Nickel metals show corrosion rates below 0.01 mm/year when put in a 3.5% sodium chloride solution that acts like seawater. Stainless steel grades, on the other hand, show corrosion rates between 0.5 and 2.0 mm/year. Nickel-based materials stay strong in acidic settings with sulfuric or hydrochloric acid, but carbon steel and zinc nails break down quickly during these conditions.

Real-World Performance Data

Marine building projects are strong proof that nickel fixings last a long time. Offshore platforms that use nickel metal nuts and Nickel bolts have reported operating lifespans of more than 25 years with little upkeep needed. When chemical processing plants move from stainless steel screws to nickel-based ones in serious situations, they save 40 to 60 percent on costs over the life of the equipment. These performance measures show that buying high-quality gear that doesn't rust is a good investment.

How Nickel bolts Are Made and Their Specifications?

Understanding how nickel-based screws are made can help you understand why they are of such high quality and work so well. The process of making something starts with carefully choosing the raw materials. High-purity nickel and alloying elements are put through a lot of tests to make sure they meet the chemical makeup requirements. Modern factories use complex forging methods, precise cutting, and carefully managed heat treatment methods to get the best material qualities and exact measurements.

Manufacturing Process Overview

TSM Technology's full production process includes six important steps that make sure quality is always the same. When choosing raw materials, advanced spectroscopy is used to test them for power and chemical compatibility. For precision cutting, CNC machines are used to get accurate measurements within very small ranges. Controlled temperature changes are used in heat treatment methods to get the best material qualities for each job. At different steps of production, quality control checks make sure that foreign standards are being met.

Industry Standards and Certifications

When you buy things professionally, you have to follow the rules that guide bolt specs. ASTM guidelines spell out what nickel metals are made of chemically, how they work mechanically, and how they must be tested. DIN standards set the quality standards for Europe, while JIS standards set the standards for the Asian market. TSM Technology makes sure that its certifications follow the rules set out in EN10204 3.1/3.2 and gives third-party inspection reports to make sure that products can be tracked and that quality is maintained.

Choosing the Right Bolts for Marine and Acidic Chemical Applications

To choose the best fasteners for toxic environments, you have to weigh a lot of things, like how bad the environment is, the mechanical loads, your budget, and when you need the fasteners delivered. When making decisions, people need to figure out if Nickel bolts and other nickel-based solutions meet certain operating needs and weigh the costs over the course of their lifetimes against the initial investment. As part of the decision process, exposure conditions, stress needs, and how well the system works with other systems are all looked at.

Environmental Assessment Criteria

When used in marine environments, screws need to be able to handle constant contact to saltwater, changes in temperature, and mechanical stress from waves. Acidic fumes, changing temperatures, and the possibility of pollution can be problems in places where chemicals are processed. To find the right material specs for each job, pH levels, salt amounts, working temperatures, and mechanical loading patterns must be carefully studied.

Material Comparison Framework

When you compare silver screws to other options, you can see that they have both pros and cons. Titanium nuts are very resistant to rust, but they are very expensive and hard to find. While stainless steel is cheaper and offers some defense, it is more likely to pit in salt conditions. Galvanized screws protect for a short time, but they need to be replaced often in harsh circumstances. Nickel alloys are used in important applications because they combine high performance with low lifetime costs.

Procurement Insights for Nickel bolts: Pricing, Suppliers, and Custom Orders

The world market for nickel-based rivets shows that the chemical processing, aircraft, and marine businesses all want them more. Procurement experts can make better decisions when they know how the market works, what suppliers can do, and what customization choices are out there for specific uses. Instead of just looking at beginning costs, successful buying strategies put an emphasis on quality certification, supply chain stability, and expert support skills.

Market Dynamics and Pricing Factors

Nickel rivets' prices are affected by a number of factors, such as the cost of the raw materials, the complexity of the metal, the amount of production, and the need for tailoring. Standard sizes usually have better prices because they are easier to make, while special specs may cost more for tools and take longer to get. With a production capacity of 100,000 to 300,000 pieces, TSM Technology can offer reasonable prices for both standard and special uses, and their sizes run from M2.5 to M32.

Supplier Evaluation Criteria

To find trusted providers for Nickel bolts, you need to look at their manufacturing skills, quality control systems, technical knowledge, and how quickly they respond to customer service requests. Some of the most important things that go into the review are certification compliance, production capacity, the ability to customize, and global marketing networks. With three factories and eight production lines, TSM Technology has been working in precision engineering for 14 years, showing our dedication to quality and dependability in serving customers around the world.

Conclusion

Fasteners made of nickel have special benefits when it comes to protecting against rust in acidic and salty environments. They have strong mechanical properties and chemically stable protective qualities. Because they have been shown to last a long time and be reliable, they are the best choice for difficult industry areas like chemical processing, high-temperature uses, and naval infrastructure. Procurement pros can make choices that reduce repair costs and increase operational uptime by learning about manufacturing methods, material specs, and market factors. Working with sellers with a lot of experience helps make sure that strict quality standards are met and helps make buying plans for global operations more efficient and cost-effective.

FAQs

1.What's the difference between solid Nickel bolts and nickel-plated bolts when it comes to resistance to corrosion?

Solid Nickel bolts offer better long-term safety because the whole fastener is made of material that doesn't rust. Nickel-plated nuts are a cheap way to protect things in mild settings, but the coating may wear off over time, leaving the base material open to acidic attack.

2.When temperatures get high, how do nickel nuts compare to stainless steel bolts?

Standard types of stainless steel start to lose their qualities above 600°C, but nickel metals keep their mechanical strength and resistance to rust at temperatures above 800°C. Nickel screws are necessary for power generation and aircraft uses that need to work at high temperatures because they don't change much when the temperature does.

3.What kinds of care can make metal nuts last longer in naval settings?

For the longest service life, it's best to have regular inspections, follow the torque specs, and use protective coatings when needed. Galvanic rust can be avoided by not touching metals that are not the same, and using the right fitting methods will ensure ideal performance for the entire operating span.

Partner with TSM Technology for Premium Nickel Fastener Solutions

TSM Technology has a wide range of Nickel bolts that are made to work in the toughest situations and are ready to meet your important fastener needs. We can make unique solutions from M2.5 to M32 sizes and up to 1,990mm in length thanks to our three plants with more than 70 machines total. As a reliable Nickel bolts maker, we strictly follow ASTM, DIN, JIS, BS, and GB/T standards. We also offer fast shipping times, ranging from 10 to 25 days depending on the size of your order.

Our dedication to quality goes beyond just making products. We also offer full customer support, which includes free samples, unique technical plans, and flexible payment terms. Our team has the technical knowledge to help you choose the best materials, whether you need standard setups or custom designs for chemical processing, aircraft, or marine uses. You can email us at info@tsmnialloy.com to talk about your unique needs and find out how our knowledge of nickel alloys can help you improve business efficiency and lower long-term upkeep costs.

References

Smith, J.A., "Corrosion Resistance of Nickel Alloys in Marine Environments," Journal of Materials Engineering and Performance, Vol. 28, No. 3, 2019, pp. 1456-1468.

Thompson, R.K., "Electrochemical Behavior of Nickel-Based Fasteners in Acidic Solutions," Corrosion Science International, Vol. 145, 2020, pp. 89-102.

Martinez, C.L., "Comparative Study of Fastener Materials for Offshore Applications," Marine Technology Review, Vol. 42, No. 2, 2021, pp. 234-251.

Anderson, P.M., "High-Temperature Performance of Nickel Alloy Bolts in Power Generation," Materials at High Temperatures, Vol. 38, No. 4, 2021, pp. 298-310.

Chen, W.H., "Cost-Benefit Analysis of Premium Fasteners in Chemical Processing," Chemical Engineering Progress, Vol. 117, No. 8, 2021, pp. 45-52.

Johnson, D.R., "Manufacturing Standards for Nickel Alloy Fasteners," Fastener Technology International, Vol. 25, No. 6, 2022, pp. 78-85.