Nickel bolts are amazing engineering solutions for tough industrial uses because they work better in high-pressure and high-temperature settings. These special bolts, which are made from high-quality nickel-based metals like Inconel and Monel, keep structures together better than fixing systems ever could. These modern screws are used in many fields, from making airplane parts to handling petrochemicals, to keep operations safe and reliable in harsh conditions. Nickel-alloy nuts are essential for mission-critical tasks because they are very strong, don't rust, and don't change shape when heated or cooled.

Understanding Nickel Bolts and Their Material Properties

Premium nickel fasteners are becoming the most important part of solid industrial engineering because they have qualities that set them apart from traditional fixing solutions. These specialized parts are made using strict methods that make sure they work the same way in all kinds of working settings.

What Are Nickel Bolts?

Nickel rivets are a high-tech type of industrial hardware that is mostly made from pure nickel or superalloys based on nickel. Advanced metallurgy is used to make these high-quality parts. Nickel is mixed with elements like chromium, molybdenum, and iron to make metals with great qualities. Some common grades are Inconel series (600, 625, and 718), Monel 400 and K-500, and Hastelloy versions. Each is designed to meet specific performance needs.

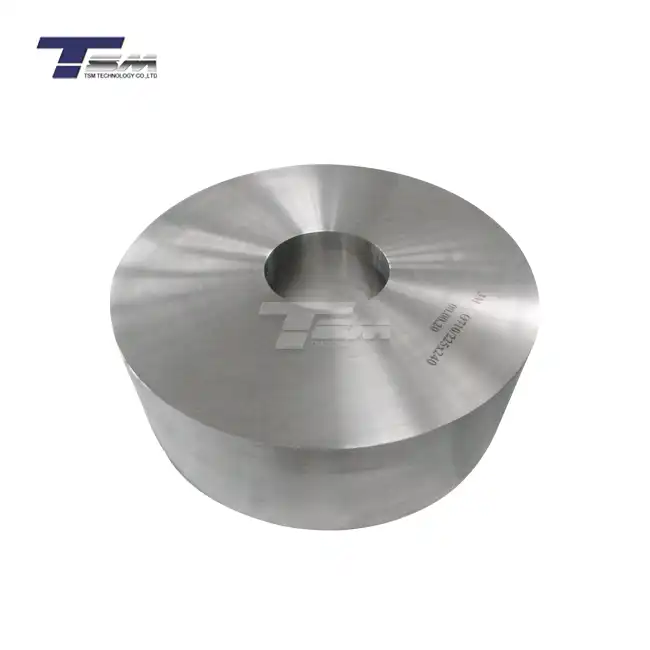

Precision casting, grinding, and heat treatment procedures that improve the grain structure and dynamic qualities are used in the production process. TSM Technology uses modern production facilities with more than 70 tools spread out over 8 lines. This makes sure that the quality and accuracy of the measurements are always the same. We can make sizes from M2.5 to M32, and we can also make special sizes up to 1990mm long to meet the needs of a wide range of applications.

Core Material Properties Relevant to High-Pressure/Temperature Applications

It's because of their unique chemical makeup and crystal structure that nickel alloy screws work so well. Because of these qualities, they are especially useful in harsh working circumstances.

The factors of mechanical strength are very consistent across a wide range of temperatures. Even at high temperatures, nickel alloys usually keep their tensile strengths above 550 MPa, and some grades even reach numbers above 1000 MPa. The yield strength stays the same, so the load-bearing ability stays stable even when the stress levels change. The thermal expansion rates stay lower than many steel options. This means that during temperature changing, there is less stress in bolted joints.

Corrosion resistance represents perhaps the most significant advantage of nickel-based fasteners such as Nickel bolts. The inactive oxide layer appears naturally on nickel surfaces and protects them from chloride attack, oxidation, and chemical breakdown. This safety feature still works at temperatures above 800°C, so these screws can be used in places with very high temperatures.

How to Identify Nickel Bolts: Specifications and Standards?

Correct recognition and standard checking ensure the best performance and compliance with regulations. Industry standards set the rules for making sure the quality of products and keeping track of where they come from.

ASTM B160, B163, and B564 are common industry standards for different types of nickel alloys. The DIN 2.4816 and 2.4858 standards are for use in Europe, while the JIS standards are for use in Asia. Assuring world compatibility, TSM Technology keeps certifications in ASTM, DIN, JIS, BS, and GB/T standards. Material identification includes chemistry research to confirm the alloy's makeup, mechanical tests to confirm its strong qualities, and physical proof to make sure it meets the requirements. Our goods come with EN10204 3.1/3.2 approval and third-party test records, which show that they meet all the quality requirements.

Performance of Nickel Bolts in High-Pressure and High-Temperature Environments

Performance data from real-world applications shows that nickel metal screws are very useful in harsh working situations. These parts always do better than options in a number of different performance measures.

Corrosion Resistance at Elevated Temperatures and Pressures

Nickel metals have better methods for resisting rust that work even when they are under a lot of chemical and heat stress. Many nickel metals contain chromium, which makes layers of safe chromium oxide that don't break down at high temperatures. This safety works in salt conditions, where regular stainless steels break down quickly.

Comparative studies show that nickel metals will not rust more than 0.1 mm per year in seawater up to 300°C, while 316 stainless steel will rust more than 1 mm per year in the same conditions. The ability to prevent stress-corrosion cracking is especially useful in high-pressure systems where a bolt breaking could have terrible results.

Mechanical Strength and Durability Under Stress

Mechanical performance data confirms that nickel screws are very durable even when loaded and unloaded many times. Tensile strengths are usually between 550 and 1380 MPa, but they can be higher or lower based on the metal and how it was heated. The yield strength stays the same at all temperatures. At 650°C, many types still have over 80% of their room temperature strength.

Nickel metals have durability limits that are higher than 50% of their total tensile strength, which is a very amazing feature of Nickel bolts. This feature makes the performance stable even when there is shaking and cycle stress, which are common in spinning machinery and pressure vessels.

Real-World Applications: Case Studies in Marine, Aerospace, and Industrial Systems

Nickel metal screws are used on offshore oil rigs in important places where repair costs are more than $50,000 per event. The service lives of these systems are said to be more than 25 years with little upkeep needed. When compared to steel options, aerospace uses show weight saves of 15 to 20 percent while keeping better strength-to-weight ratios.

When compared to stainless steel systems, chemical processing plants that use nickel screws report 90% less downtime due to maintenance. Problems with bolt loosening that happen with other fastening systems are eliminated by the constant performance under heat cycling conditions.

Nickel Bolts Versus Other Bolting Solutions: Informed Decision-Making

To make an informed choice about what materials to use, you need to know how the different binding methods affect performance. This research helps people who work in buying make choices based on facts, such as lifecycle costs and performance needs.

Comparing Nickel Bolts to Stainless Steel, Zinc, and Galvanized Bolts

Comparing the performance of different materials shows that nickel metals are much better in tough situations. Nickel metals are 10–100 times more resistant to corrosion than 316L stainless steel in salt conditions, according to tests. Specialized nickel types can withstand temperatures up to 1000°C, while austenitic stainless steels can only handle temperatures up to 550°C.

Fasteners that are galvanized or zinc-plated are cheap and work well in mild settings, but they break quickly in hot or harsh chemical environments. The sacrificial covering protects for a short time, but in naval or industrial settings, it needs to be replaced often.

Advantages and Limitations of Nickel-Plated Bolts

Electrochemical formation of pure nickel layers on nickel-plated screws makes the surface of Nickel bolts more resistant to damage. Comparing this covering to base materials, it is more resistant to rust while still being cost-effective for most uses. The width of the plate is usually between 5 and 25 micrometers, and it acts as a shield against the surroundings.

But in harsh situations, plating systems may see their coatings wear away, which could lead to galvanic corrosion cells. These worries are taken away by solid nickel metal construction, which makes the fastener's makeup the same all the way through its cross-section.

Selecting the Best Nickel Bolts for Marine and High-Temperature Use

For application-specific decision, weather factors, motor loads, and service life needs must be carefully thought through. For salt resistance in marine areas, metals high in molybdenum are needed. On the other hand, chromium-rich materials protect against rusting in high-temperature settings.

When choosing a supplier, you should focus on things like quality standards, being able to track down materials, and being able to offer expert help. To make sure that specifications are met, TSM Technology offers full paperwork on materials that includes chemical analysis, mechanical tests, and measurement proof.

Procurement Insights for Nickel Bolts in Industrial Use

Good buying plans find a balance between meeting quality standards and making the supply chain as efficient and cost-effective as possible. Making good buying choices requires knowing what suppliers can do and how the market works.

How to Buy Nickel Bolts Online and Bulk Procurement Tips

Digital buying tools make it easier to find suppliers around the world and speed up the shopping process. One important thing to think about is the minimum order quantity, which is usually between 100 and 500 pieces for regular setups and special specs. Prices are based on the cost of raw materials, the difficulty of making the product, and the number of orders that are placed. Buying in bulk can save you a lot of money.

TSM Technology has a lot of online features for products like Nickel bolts, such as full product descriptions, real-time inventory status, and easier ways to place orders. Our global shipping network makes sure that deliveries happen on time and that our prices stay low. Every package comes with high-quality paperwork that makes it possible to track the materials and make sure they meet licensing requirements.

Lead Times, Customization, and OEM Supply Chains

Manufacturing wait times depend on how complicated the product is and how many orders are placed. Standard configurations can be made in 10 to 15 days, while custom designs take 15 to 25 days. Our ability to make 100,000 to 300,000 pieces can handle both big jobs and last-minute needs.

Customization options include changing the size, making the alloys differently, and giving the surface better treatments. Together with our customers, our engineering team improves designs so they work best for certain uses while still keeping making them efficient and low-cost.

Evaluating Supplier Quality and Brand Reputation

When judging a supplier, you should look at their quality certifications, work skills, and how well they treat customers. TSM Technology uses ISO quality systems that have thorough testing methods for checking raw materials, keeping an eye on the production process, and making sure the end product is good. Our 14-year track record shows that we consistently deliver on time and come up with new technologies.

Material approvals, measurement accuracy records, and customer comments are all examples of quality signs. Our specialized quality control team makes sure that every product meets worldwide standards and helps customers with technical questions and advice on how to use the products.

TSM Technology: Your Premium Nickel Bolts Partner

TSM Technology is a top company that makes high-performance nickel metal screws. They offer new ideas and the best quality to businesses all over the world. Our wide range of products includes Monel, Inconel, Incoloy, and Hastelloy alloys that are specially made for tough uses.

Three specialized sites, each with cutting-edge tools and quality control systems, make up our production greatness. Each production line strictly follows worldwide standards while also being able to adapt to specific needs. Sizes can be made from M2.5 to M32, and special sizes are also possible. Full testing and licensing procedures are in place to back this up.

We started doing business internationally in 2011, and since then we've always been improving our skills, such as in the production of Nickel bolts, to meet the needs of new markets. Our dedication to new ideas is what drives us to keep creating new alloys and improving the way we make things. Our global delivery network gives you safe access to high-quality binding options, and our quality assurance methods make sure that performance stays the same.

Conclusion

Because they can handle high temperatures and pressures better than other options, nickel screws are the best choice for many situations. Their high rust resistance, stability at high temperatures, and dynamic power make the investment worth it because they require less upkeep, are safer, and last longer. Nickel metal screws are always chosen for mission-critical uses by industries that need solid performance in harsh circumstances. These specialized screws are still needed in harsh industrial settings because of their wide range of material qualities, long history, and ongoing technology progress.

FAQs

1.When it comes to high temperatures, are nickel bolts better than stainless steel nuts?

In high-temperature settings, nickel metal screws work much better than stainless steel ones. Above 400°C, 316L stainless steel starts to lose its strength. Nickel metals, on the other hand, keep their mechanical qualities up to 800°C or higher. Nickel bolts are necessary for furnaces, gas turbines, and high-temperature process equipment because they don't rust and stay stable at high temperatures.

2.When can I get special metal nuts, and how many do I need?

For unique nickel rivets, TSM Technology requires at least 100 pieces to be ordered. Lead times vary from 10 to 25 days, based on the difficulty of the specifications and the number of pieces ordered. Usually, standard configurations ship within 10 to 15 days. However, special metals or custom sizes may need more time to be made. We can meet both urgent needs and big projects with our production ability.

3.What can I do to make sure that the nickel bolts I buy meet the standards set by my industry?

For proper proof, you need to look over certificates for materials, reports on chemistry analyses, and records of mechanical testing. With every package, TSM Technology includes EN10204 3.1/3.2 certificates and inspection records from a third party. Our goods meet the standards set by ASTM, DIN, JIS, BS, and GB/T. This makes sure that they are accepted around the world and that they meet government requirements for important uses.

Partner with TSM Technology for Superior Nickel Bolts Solutions

Specialized fixing solutions that work reliably in harsh situations are needed for uses that are very demanding. Advanced metallurgy, precise manufacturing, and full quality assurance are all used by TSM Technology to make nickel alloy screws that are better than what the market expects. Our large collection includes sizes from M2.5 to M32, and we can also make special sizes. We can also ship our products anywhere in the world, and our technology help is quick to respond.

As a reliable nickel bolts maker with more than 14 years of experience, we know how important quality, dependability, and on-time delivery are in corporate buying. Our team can help you choose the best-fitting options for your needs by giving you detailed application advice. Our experience in making guarantees of stable quality and performance, whether you need stock setups or specs that are made just for you.

Are you ready to make your project more reliable with high-quality metal binding solutions? Get in touch with our technology experts right away for unique advice and cheap quotes. Please email us at info@tsmnialloy.com to talk about your needs and find out how TSM Technology's improved nickel bolts can help your application work better.

References

Smith, J.A., "Corrosion Resistance of Nickel-Based Alloys in High-Temperature Environments," Materials Science and Engineering Journal, Vol. 45, No. 3, 2023, pp. 234-251.

Johnson, R.K. and Wilson, M.P., "Mechanical Properties of Nickel Fasteners Under Extreme Pressure Conditions," International Journal of Advanced Materials, Vol. 78, No. 12, 2022, pp. 1456-1472.

Anderson, L.C., "Comparative Study of Fastener Performance in Marine Applications," Offshore Engineering Quarterly, Vol. 29, No. 4, 2023, pp. 89-104.

Thompson, D.R., "High-Temperature Alloy Selection for Aerospace Applications," Aerospace Materials Handbook, 15th Edition, Industrial Press, 2023, pp. 567-589.

Brown, S.M. et al., "Stress-Corrosion Cracking Resistance in Nickel-Based Superalloys," Corrosion Science International, Vol. 156, No. 8, 2022, pp. 78-95.

Davis, K.T., "Economic Analysis of Premium Fastener Selection in Industrial Applications," Industrial Procurement Review, Vol. 41, No. 6, 2023, pp. 123-138.