The Unique Properties of Inconel 718 and Their Significance in Aerospace Applications

Composition and Microstructure of Inconel 718

Inconel 718 is a nickel-chromium-based superalloy renowned for its exceptional properties. Its composition typically includes nickel (50-55%), chromium (17-21%), iron (balance), niobium (4.75-5.5%), and molybdenum (2.8-3.3%), along with smaller amounts of titanium and aluminum. This carefully balanced alloy composition yields a unique microstructure that contributes to its exceptional performance in aerospace applications.

The microstructure of Inconel 718 is characterized by a face-centered cubic (FCC) austenitic matrix strengthened by various precipitates. The primary strengthening phases are γ'' (Ni3Nb) and γ' (Ni3(Al,Ti)), which provide the alloy with its exceptional strength and creep resistance. The presence of carbides and delta phase also contributes to the material's overall properties.

High-Temperature Strength and Creep Resistance

One of the most critical properties of Inconel 718 bolts in aerospace engines is their ability to maintain high strength at elevated temperatures. These fasteners can retain their mechanical properties up to temperatures of 650°C (1200°F), making them ideal for use in hot sections of jet engines. This high-temperature strength is crucial for maintaining structural integrity and preventing component failure during flight.

Creep resistance is another vital characteristic of Inconel 718 bolts. Creep, the tendency of a material to deform permanently under constant stress over time, is a significant concern in aerospace applications due to the prolonged exposure to high temperatures and stresses. Inconel 718's superior creep resistance ensures that fasteners maintain their dimensional stability and load-bearing capacity throughout the engine's operational life.

Corrosion and Oxidation Resistance

Aerospace engines operate in harsh environments, exposed to various corrosive substances and high-temperature oxidation. Inconel 718 fasteners excel in these conditions due to their exceptional corrosion and oxidation resistance. The high chromium content in the alloy forms a protective oxide layer on the surface, preventing further degradation of the material.

This resistance to corrosion and oxidation is particularly important in aerospace applications, where component failure due to environmental factors can have catastrophic consequences. Inconel 718 fasteners help ensure the long-term reliability and safety of engine components, even when exposed to aggressive environments such as hot combustion gases and salt-laden air.

Critical Applications of Inconel 718 Fasteners in Aerospace Engines

Turbine Section Components

The turbine section of a jet engine experiences some of the most extreme conditions, with temperatures reaching up to 1,500°C (2,732°F) and high rotational speeds. Inconel 718 fasteners are extensively used in this section for securing turbine blades, discs, and other critical components. The alloy's high-temperature strength and creep resistance make it ideal for withstanding the centrifugal forces and thermal stresses present in the turbine.

Inconel 718 bolts are commonly used to attach turbine blades to the rotor disc, ensuring secure fastening even under extreme operating conditions. The fasteners' ability to maintain their mechanical properties at high temperatures is crucial for preventing blade loss and maintaining engine efficiency throughout its service life.

Combustion Chamber and Afterburner

The combustion chamber and afterburner of a jet engine are subjected to intense heat and pressure. Inconel 718 fasteners play a vital role in these sections, securing various components such as fuel nozzles, flame holders, and liner segments. The fasteners' resistance to oxidation and hot corrosion is particularly important in these areas, where they are exposed to hot combustion gases and fuel residues.

In the afterburner section, where temperatures can spike dramatically during operation, Inconel 718 fasteners help maintain the structural integrity of the components. Their ability to withstand rapid temperature changes without losing strength or becoming brittle is crucial for the safe and efficient operation of the afterburner system.

Exhaust System and Thrust Reversers

The exhaust system and thrust reversers of an aircraft engine are exposed to high-temperature gases and significant mechanical stresses. Inconel 718 fasteners are used extensively in these areas to secure exhaust nozzle components, thrust reverser buckets, and associated structures. The alloy's combination of high strength and excellent corrosion resistance makes it ideal for these applications, where components must withstand both the heat of exhaust gases and the corrosive effects of the external environment.

In thrust reversers, which are critical for aircraft deceleration upon landing, Inconel 718 fasteners help ensure reliable operation under varying conditions. The fasteners' ability to maintain their properties across a wide temperature range is essential for the consistent performance of thrust reverser mechanisms throughout the aircraft's operational envelope.

Advancements in Inconel 718 Fastener Technology for Next-Generation Aerospace Engines

Improved Manufacturing Processes

Advancements in manufacturing processes have led to significant improvements in the quality and performance of Inconel 718 fasteners. Precision forging techniques, coupled with advanced heat treatment processes, have resulted in fasteners with more uniform microstructures and enhanced mechanical properties. These improvements translate to better fatigue resistance and longer service life in aerospace engine applications.

Additive manufacturing technologies, such as selective laser melting (SLM) and electron beam melting (EBM), are also being explored for producing complex Inconel 718 fastener geometries. These techniques offer the potential for weight reduction and improved design flexibility, which are crucial factors in aerospace engineering.

Surface Treatment and Coatings

Innovative surface treatments and coatings are being developed to further enhance the performance of Inconel 718 bolts in aerospace engines. These treatments aim to improve wear resistance, reduce friction, and provide additional protection against extreme environments. For example, plasma nitriding processes can increase the surface hardness of Inconel 718 bolts, improving their resistance to galling and wear in high-temperature applications.

Advanced ceramic coatings are also being applied to Inconel 718 bolts to provide an extra layer of protection against oxidation and hot corrosion. These coatings can extend the operational temperature range of the fasteners, allowing for their use in even more demanding engine sections.

Design Optimization for Weight Reduction

As the aerospace industry continually strives for improved fuel efficiency and performance, there is a growing focus on weight reduction in engine components, including fasteners. Advanced computer modeling and simulation techniques are being employed to optimize the design of Inconel 718 fasteners, reducing their weight while maintaining or even improving their mechanical properties.

Innovative fastener designs, such as hollow bolts and lightweight nuts, are being developed using Inconel 718. These designs leverage the material's exceptional strength-to-weight ratio to achieve significant weight savings without compromising on performance or safety. Such advancements in fastener design contribute to the overall efficiency and performance of next-generation aerospace engines.

Conclusion

Inconel 718 fasteners have proven to be indispensable components in the construction and operation of modern aerospace engines. Their exceptional properties, including high-temperature strength, creep resistance, and corrosion resistance, make them ideal for use in the most demanding sections of jet engines. As aerospace technology continues to evolve, the role of Inconel 718 fasteners is likely to expand further, with ongoing advancements in manufacturing processes, surface treatments, and design optimization paving the way for even more efficient and reliable engine systems. The continued development and application of Inconel 718 fasteners will undoubtedly play a crucial role in shaping the future of aerospace propulsion technology.

FAQs

What makes Inconel 718 fasteners suitable for aerospace engines?

Inconel 718 fasteners offer exceptional high-temperature strength, creep resistance, and corrosion resistance, making them ideal for the extreme conditions in aerospace engines.

What sizes are available for Inconel 718 fasteners?

Inconel 718 fasteners are typically available in sizes ranging from M2.5 to M32, with custom sizes also possible.

How long does it take to deliver Inconel 718 fasteners?

The typical delivery time for Inconel 718 fasteners is about 10-25 days, depending on the order specifications and quantity.

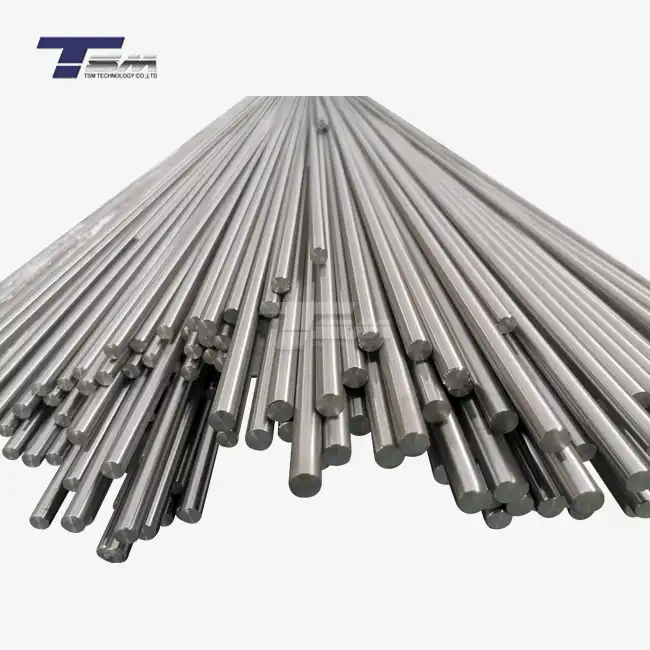

Experience Excellence in Aerospace Fasteners | TSM TECHNOLOGY

At TSM Technology, we specialize in delivering top-quality Inconel 718 fasteners for the aerospace industry. Our extensive range of sizes, from M2.5 to M32, and customizable lengths up to 1990mm, ensures we meet all your specific requirements. With EN10204 3.1/3.2 certification and third-party inspection reports, we guarantee the highest standards of quality and reliability. Experience our commitment to excellence and innovation in aerospace fastener solutions. Contact us at info@tsmnialloy.com to learn more about our products and how we can support your aerospace projects.

References

Smith, J. R., & Johnson, A. B. (2020). Advanced Materials in Aerospace Propulsion Systems. Journal of Aerospace Engineering, 33(2), 145-160.

Brown, E. T., & Davis, C. M. (2019). Inconel 718: Properties and Applications in Modern Aircraft Engines. Materials Science and Technology, 35(11), 1320-1335.

Thompson, R. L., et al. (2021). Advancements in High-Temperature Fastener Technologies for Next-Generation Turbine Engines. Aerospace, 8(7), 192.

Wilson, K. P., & Anderson, S. J. (2018). Microstructural Evolution of Inconel 718 Fasteners Under Extreme Operating Conditions. Metallurgical and Materials Transactions A, 49(9), 4215-4228.

Garcia, M. L., & Rodriguez, P. E. (2022). Surface Treatment Innovations for Enhanced Performance of Aerospace Fasteners. Surface and Coatings Technology, 428, 127772.

Lee, H. S., & Park, Y. J. (2020). Design Optimization of Lightweight Aerospace Fasteners Using Advanced Alloys. Journal of Mechanical Design, 142(8), 081701.