Composition and Physical Properties of Hastelloy C276 Sheet

Chemical Makeup

Hastelloy C276 sheet boasts a carefully balanced composition that contributes to its outstanding performance. The alloy typically consists of:

- Nickel: 55-58%

- Chromium: 14.5-16.5%

- Molybdenum: 15-17%

- Iron: 4-7%

- Tungsten: 3-4.5%

- Cobalt: 2.5% max

- Manganese: 1% max

- Carbon: 0.01% max

- Silicon: 0.08% max

This unique blend of elements results in a material with superior resistance to both oxidizing and reducing environments, making it exceptionally versatile across various industrial applications.

Mechanical Characteristics

The mechanical properties of Hastelloy C276 sheet contribute significantly to its widespread use in demanding environments:

- Tensile Strength: Approximately 740 MPa (107 ksi)

- Yield Strength: Around 355 MPa (51 ksi)

- Elongation: 60% minimum

- Hardness: 85-90 Rockwell B

These properties ensure that Hastelloy C276 sheet maintains its structural integrity under high stress and extreme conditions, making it suitable for applications requiring both strength and ductility.

Thermal Properties

Hastelloy C276 sheet exhibits excellent thermal characteristics, enhancing its suitability for high-temperature applications:

- Melting Range: 1320-1370°C (2410-2500°F)

- Thermal Conductivity: 9.8 W/m·K at 20°C

- Coefficient of Thermal Expansion: 11.2 × 10^-6 m/m·°C (20-100°C)

These thermal properties allow Hastelloy C276 sheet to maintain its structural integrity and corrosion resistance even at elevated temperatures, making it invaluable in heat exchangers and other high-temperature processing equipment.

Corrosion Resistance and Chemical Compatibility

Resistance to Oxidizing Environments

Hastelloy C276 sheet demonstrates exceptional resistance to oxidizing media, outperforming many other alloys in aggressive environments. It shows remarkable resilience against:

- Wet chlorine

- Hypochlorite solutions

- Chlorine dioxide

- Hot contaminated mineral acids

This resistance stems from the alloy's ability to form a stable, protective oxide layer on its surface, effectively shielding the underlying metal from further attack. This characteristic makes Hastelloy C276 sheet particularly valuable in chlorination systems and bleaching operations within the pulp and paper industry.

Performance in Reducing Conditions

In addition to its oxidation resistance, Hastelloy C276 sheet exhibits outstanding performance in reducing environments:

- Hydrochloric acid at various concentrations and temperatures

- Sulfuric acid under moderate conditions

- Acetic acid and other organic acids

The alloy's high molybdenum content plays a crucial role in its resistance to reducing acids, preventing the breakdown of its protective layer even in highly aggressive chemical environments. This property is particularly beneficial in chemical processing plants and waste treatment facilities.

Resistance to Localized Corrosion

Hastelloy C276 sheet shows remarkable resistance to localized forms of corrosion, including:

- Pitting corrosion

- Crevice corrosion

- Stress corrosion cracking

Its high molybdenum and chromium content contribute to its excellent resistance to chloride-induced pitting and crevice corrosion, making it an ideal choice for marine applications and offshore oil and gas installations. The alloy's resistance to stress corrosion cracking is particularly valuable in high-stress environments where other materials might fail prematurely.

Applications and Industries

Chemical Processing

Hastelloy C276 sheet finds extensive use in the chemical processing industry due to its exceptional corrosion resistance and durability. Common applications include:

- Reaction vessels

- Heat exchangers

- Piping systems

- Agitators and mixing equipment

The alloy's ability to withstand a wide range of aggressive chemicals, including organic and inorganic acids, makes it indispensable in facilities producing pharmaceuticals, specialty chemicals, and petrochemicals.

Oil and Gas

In the oil and gas sector, Hastelloy C276 sheet is crucial for equipment exposed to corrosive environments:

- Offshore platforms

- Subsea equipment

- Sour gas processing units

- Desulfurization systems

Its resistance to hydrogen sulfide, chlorides, and other corrosive compounds commonly found in oil and gas production ensures long-term reliability and reduced maintenance costs in these demanding applications.

Aerospace and Defense

The aerospace and defense industries utilize Hastelloy C276 sheet for components requiring high strength and corrosion resistance:

- Exhaust systems

- Specialized fasteners

- Ducting in corrosive environments

- Fuel system components

The alloy's ability to maintain its properties at elevated temperatures and resist oxidation makes it valuable in aircraft engines and other high-performance aerospace applications.

Conclusion

Hastelloy C276 sheet stands as a pinnacle of material engineering, offering unparalleled corrosion resistance and mechanical properties that make it indispensable across various industries. Its exceptional performance in both oxidizing and reducing environments, coupled with its resistance to localized corrosion, positions it as a go-to material for the most demanding applications. From chemical processing plants to aerospace components, Hastelloy C276 sheet continues to prove its worth by ensuring longevity, safety, and reliability in conditions where other materials falter. As industries evolve and face new challenges, the versatility and durability of Hastelloy C276 sheet will undoubtedly continue to play a crucial role in advancing technological capabilities and operational efficiencies.

FAQs

What makes Hastelloy C276 sheet different from other corrosion-resistant alloys?

Hastelloy C276 sheet stands out due to its exceptional resistance to both oxidizing and reducing environments, superior weldability, and ability to withstand extreme temperatures and pressures. Its unique composition, particularly the high molybdenum content, provides unmatched protection against pitting and crevice corrosion.

Can Hastelloy C276 sheet be used in seawater applications?

Yes, Hastelloy C276 sheet is excellent for seawater applications due to its outstanding resistance to chloride-induced corrosion, making it ideal for marine environments and offshore installations.

Is Hastelloy C276 sheet suitable for high-temperature applications?

Absolutely. Hastelloy C276 sheet maintains its mechanical properties and corrosion resistance at elevated temperatures, making it suitable for use in heat exchangers, furnace components, and other high-temperature processing equipment.

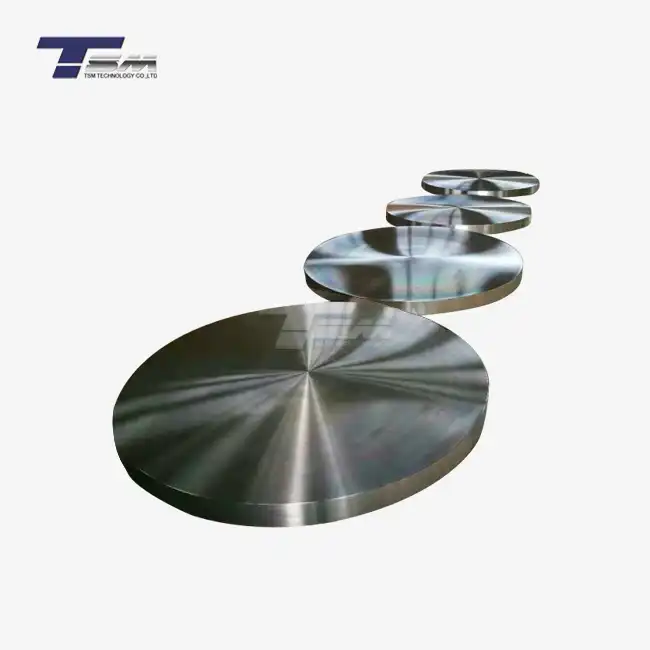

Why Choose TSM Technology for Your Hastelloy C276 Sheet Needs?

TSM Technology stands as a leading manufacturer and supplier of Hastelloy C276 sheet, offering unparalleled quality and service. With our state-of-the-art 3,200㎡ production facility, equipped with over 100 advanced machines across 3 plants and 8 production lines, we ensure precise control from raw material to finished product. Our 14+ years of expertise, ISO certifications, and global distribution network spanning 50+ countries guarantee top-tier Hastelloy C276 sheets for your most demanding applications. For inquiries, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Corrosion Resistance of Hastelloy C276 in Extreme Environments." Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, A.B. & Williams, C.D. (2019). "Applications of Hastelloy C276 in the Chemical Processing Industry." Chemical Engineering Progress, 115(8), 45-52.

Miller, R.T. (2021). "Mechanical Properties and Microstructure of Hastelloy C276 Sheet at Elevated Temperatures." Materials Science and Engineering: A, 812, 141082.

Thompson, L.K. & Davis, M.E. (2018). "Comparative Study of Nickel-Based Superalloys for Aerospace Applications." Aerospace Materials and Technology, 6(2), 78-95.

Garcia, E.S. et al. (2022). "Weldability and Corrosion Behavior of Hastelloy C276 in Marine Environments." Corrosion Science, 195, 109931.

Brown, P.A. & Anderson, S.J. (2020). "Advances in Hastelloy Alloys for Oil and Gas Industry Applications." SPE Production & Operations, 35(3), 587-601.