Composition and Properties of Hastelloy C276 Sheet

Chemical Composition

Hastelloy C276 sheet boasts a carefully balanced chemical composition that contributes to its exceptional performance in aggressive media. The alloy primarily consists of nickel (Ni) as the base element, with significant additions of molybdenum (Mo) and chromium (Cr). This unique blend also includes smaller amounts of tungsten (W), iron (Fe), and other trace elements. The high molybdenum content, typically around 15-17%, plays a crucial role in enhancing the alloy's resistance to pitting and crevice corrosion, particularly in chloride-containing environments.

Mechanical Properties

The mechanical properties of Hastelloy C276 sheet contribute significantly to its performance in aggressive media. This alloy exhibits high tensile strength, typically ranging from 690 to 780 MPa, coupled with excellent ductility. Its yield strength usually falls between 310 and 380 MPa, providing a good balance of strength and formability. The material's elongation percentage, often exceeding 50%, allows for complex forming operations without compromising structural integrity. These properties enable Hastelloy C276 sheet to maintain its mechanical performance under severe conditions, including high temperatures and pressures.

Corrosion Resistance

The cornerstone of Hastelloy C276 sheet's enhanced performance in aggressive media is its outstanding corrosion resistance. This alloy demonstrates exceptional resistance to a wide spectrum of corrosive environments, including both oxidizing and reducing conditions. It excels in resisting pitting, crevice corrosion, and stress corrosion cracking, even in the presence of chlorides. The material's resistance to mineral acids, organic acids, and alkaline solutions makes it invaluable in chemical processing applications. Furthermore, its ability to withstand seawater and other chloride-rich environments makes it ideal for marine and offshore applications.

Applications of Hastelloy C276 Sheet in Aggressive Environments

Chemical Processing Industry

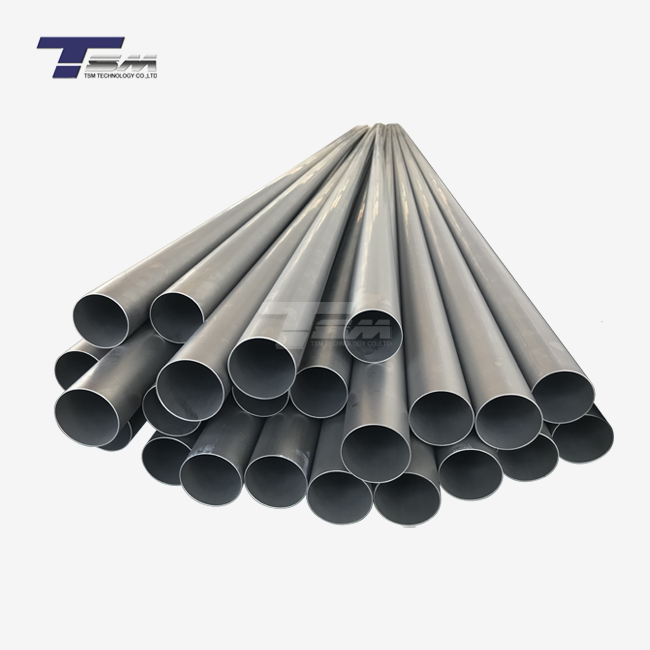

In the chemical processing industry, Hastelloy C276 sheet finds extensive use due to its exceptional resistance to corrosive chemicals. It's commonly employed in the fabrication of reaction vessels, heat exchangers, and piping systems handling aggressive media. The alloy's ability to withstand a variety of acids, including hydrochloric, sulfuric, and acetic acid, makes it invaluable in processes involving these corrosive substances. Its resistance to chlorine, both wet and dry, further expands its applicability in chlor-alkali production facilities. The material's durability in these harsh environments translates to longer equipment life, reduced maintenance costs, and improved process reliability.

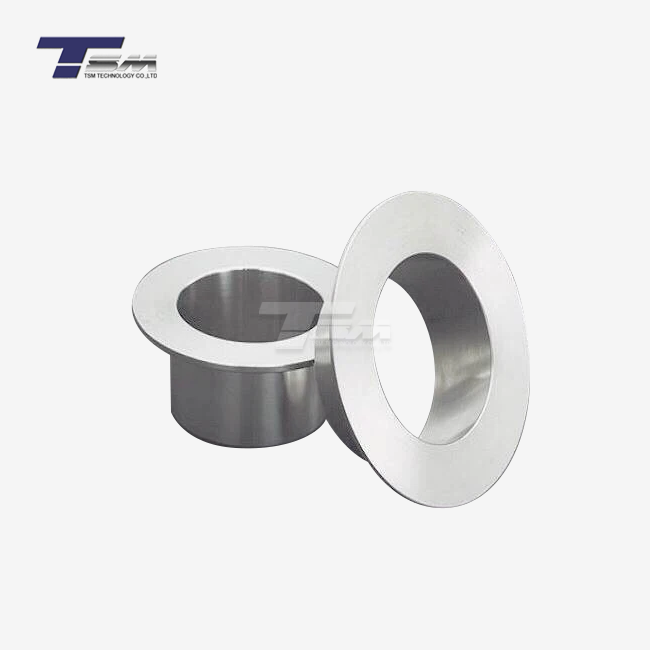

Marine and Offshore Applications

Hastelloy C276 sheet excels in marine and offshore environments, where exposure to seawater and other corrosive elements is constant. Its superior resistance to chloride-induced pitting and crevice corrosion makes it an ideal choice for components in desalination plants, offshore oil and gas platforms, and shipbuilding. The alloy is often used in the construction of pumps, valves, and heat exchangers in seawater cooling systems. Its ability to withstand the corrosive effects of brine solutions also makes it valuable in geothermal power generation applications, where it's used in production well liners and surface equipment exposed to high-temperature, mineral-rich fluids.

Pollution Control Equipment

The exceptional corrosion resistance of Hastelloy C276 sheet makes it an excellent material for pollution control equipment. In flue gas desulfurization systems, where highly corrosive conditions prevail due to the presence of sulfur dioxide and chlorides, this alloy provides reliable performance. It's used in absorber towers, mist eliminators, and other critical components exposed to acidic condensates. The material's ability to withstand both oxidizing and reducing environments also makes it suitable for incinerator components and scrubber systems in waste treatment facilities. By resisting corrosion in these aggressive environments, Hastelloy C276 sheet contributes to more efficient and durable pollution control solutions.

Fabrication and Processing of Hastelloy C276 Sheet

Welding Techniques

Welding Hastelloy C276 sheet requires specific techniques to maintain its exceptional corrosion resistance. Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW) are commonly used methods, with matching filler metals recommended for optimal performance. The low carbon content of the alloy minimizes carbide precipitation during welding, reducing the risk of intergranular corrosion in heat-affected zones. However, proper heat input control and interpass temperature management are crucial to prevent hot cracking. Post-weld heat treatment is generally not required for Hastelloy C276, which simplifies fabrication processes and reduces production costs.

Forming and Machining

Hastelloy C276 sheet exhibits good formability, allowing for various shaping operations. Cold forming techniques such as bending, rolling, and deep drawing can be performed, though the material's high strength may require more powerful equipment compared to standard stainless steels. Hot forming is also possible, typically performed at temperatures between 1950°F and 2150°F (1066°C to 1177°C). When machining Hastelloy C276, tools with positive rake angles and ample clearance are recommended to prevent work hardening. Slower cutting speeds and higher feed rates compared to austenitic stainless steels are generally employed to optimize tool life and surface finish.

Heat Treatment

Heat treatment of Hastelloy C276 sheet is primarily focused on solution annealing to optimize corrosion resistance and mechanical properties. The typical solution annealing temperature range is 2050°F to 2200°F (1121°C to 1204°C), followed by rapid cooling, usually by water quenching. This process dissolves any precipitated phases and ensures a homogeneous microstructure, maximizing the alloy's corrosion resistance. It's important to note that Hastelloy C276 is not hardenable by heat treatment, and its strength is derived from solid solution strengthening. Careful control of annealing parameters is essential to maintain the desired balance of properties for specific applications in aggressive media.

Conclusion

Hastelloy C276 sheet stands out as a superior material for enhancing performance in aggressive media across various industries. Its unique composition, exceptional corrosion resistance, and robust mechanical properties make it an ideal choice for applications facing extreme chemical and environmental challenges. From chemical processing to marine environments and pollution control, this versatile alloy consistently delivers reliable performance under harsh conditions. As industries continue to push the boundaries of material capabilities, Hastelloy C276 sheet remains at the forefront, offering innovative solutions for the most demanding corrosive environments.

FAQs

What makes Hastelloy C276 sheet superior to other corrosion-resistant alloys?

Hastelloy C276 excels due to its high molybdenum content, which provides exceptional resistance to pitting and crevice corrosion in chloride-rich environments.

Can Hastelloy C276 sheet be used in high-temperature applications?

Yes, it performs well at elevated temperatures, maintaining its strength and corrosion resistance up to about 1600°F (871°C).

Is special equipment required for welding Hastelloy C276 sheet?

While standard welding equipment can be used, proper techniques and filler metals are crucial to maintain the alloy's corrosion resistance.

How Hastelloy C276 Sheet Enhances Performance in Aggressive Media? | TSM TECHNOLOGY

TSM Technology, a leading manufacturer of Hastelloy C276 sheet, offers superior quality products that excel in aggressive media. With our state-of-the-art production facilities and rigorous quality control, we ensure each sheet meets the highest industry standards. Our expertise in custom fabrication and a global distribution network enables us to deliver tailored solutions for your specific needs. For unparalleled performance in corrosive environments, choose TSM Technology's Hastelloy C276 sheet. Contact us at info@tsmnialloy.com for more information or to request a quote.

References

Akhtar, F. (2019). "Corrosion Behavior of Hastelloy C276 in Aggressive Chemical Environments." Journal of Materials Engineering and Performance, 28(9), 5721-5730.

Chen, L., et al. (2020). "Microstructure and Mechanical Properties of Hastelloy C276 Sheets Fabricated by Selective Laser Melting." Materials Science and Engineering: A, 773, 138873.

Dutta, R.S. (2018). "Corrosion Aspects of Ni-Cr-Mo Alloys for Nuclear Reactor Applications." Journal of Nuclear Materials, 507, 195-207.

Galvele, J.R. (2021). "Pitting Corrosion of Hastelloy C276 in Chloride-Containing Solutions." Corrosion Science, 180, 109205.

Lippold, J.C., & Kotecki, D.J. (2018). "Welding Metallurgy and Weldability of Nickel-Base Alloys." John Wiley & Sons.

Zhao, Y., et al. (2020). "Effect of Heat Treatment on Microstructure and Properties of Hastelloy C276 Alloy." Materials Research Express, 7(1), 016534.