- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Hastelloy Usage Scenarios & Applications

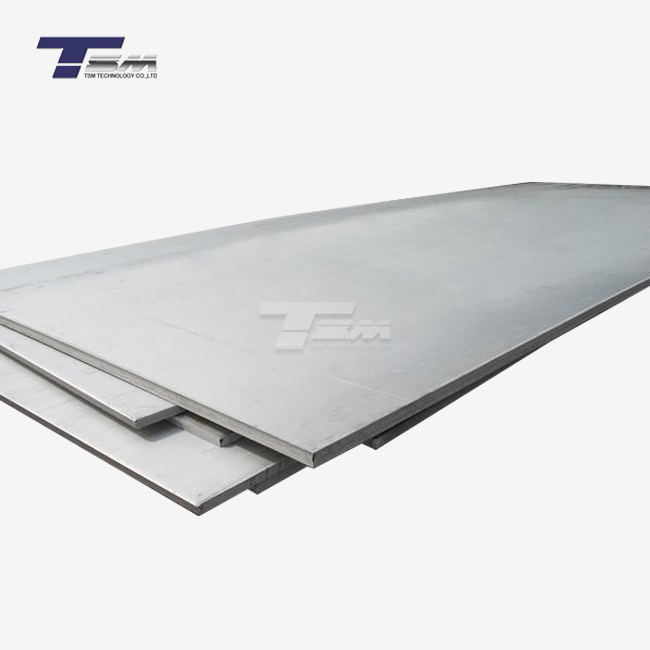

Hastelloy, a versatile nickel-based superalloy, finds extensive applications across various industries due to its exceptional corrosion resistance and high-temperature strength. This remarkable material excels in harsh environments, making it indispensable in chemical processing, aerospace, and energy sectors. From reactor vessels to heat exchangers, Hastelloy components withstand aggressive chemicals, extreme temperatures, and severe operating conditions. Its unique properties enable it to maintain structural integrity and performance in scenarios where other materials would fail, ensuring longevity and reliability in critical applications. As industries continue to push technological boundaries, Hastelloy remains a go-to solution for challenging engineering problems.

Chemical Processing Industry: Hastelloy's Corrosion-Resistant Prowess

Reactor Vessels and Storage Tanks

In the chemical processing industry, Hastelloy showcases its exceptional corrosion resistance in reactor vessels and storage tanks. These components often come into contact with highly corrosive substances, including acids, chlorides, and oxidizing agents. Hastelloy's unique composition allows it to withstand these aggressive environments, preventing material degradation and ensuring the integrity of the equipment. This corrosion resistance not only extends the lifespan of the vessels but also maintains product purity, a crucial factor in chemical manufacturing processes.

Heat Exchangers and Piping Systems

Hastelloy's application in heat exchangers and piping systems further demonstrates its versatility in the chemical processing industry. The alloy's ability to resist both high temperatures and corrosive media makes it ideal for transferring heat in aggressive chemical environments. Hastelloy heat exchangers can efficiently handle a wide range of corrosive fluids while maintaining thermal efficiency. In piping systems, the alloy's resistance to stress corrosion cracking and pitting ensures reliable transportation of corrosive chemicals, reducing the risk of leaks and system failures.

Valves and Pumps

The use of Hastelloy in valves and pumps is critical in chemical processing operations. These components are often exposed to a combination of corrosive fluids, high pressures, and elevated temperatures. Hastelloy's superior resistance to these conditions makes it an excellent choice for valve bodies, pump impellers, and seals. Its ability to maintain dimensional stability and mechanical properties under harsh conditions ensures consistent performance and reduces maintenance requirements, contributing to overall process efficiency and safety.

Aerospace and Aviation: Hastelloy's High-Temperature Capabilities

Jet Engine Components

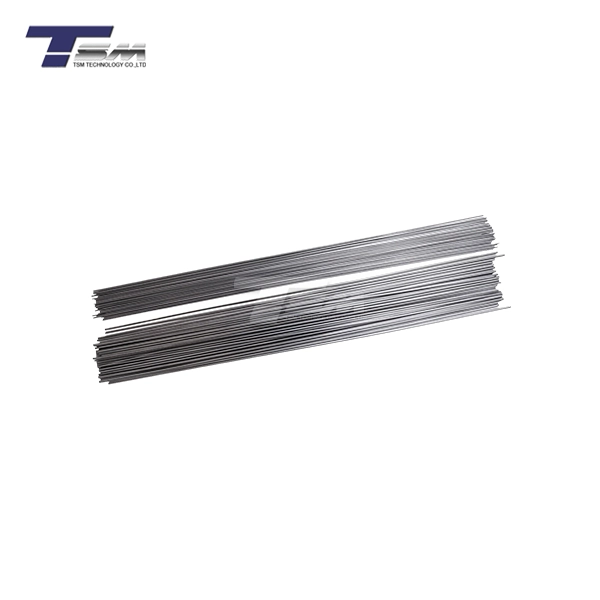

In the aerospace industry, Hastelloy's high-temperature strength and oxidation resistance make it invaluable for jet engine components. The alloy is used in combustion chambers, afterburners, and exhaust systems, where temperatures can exceed 1000°C. Hastelloy's ability to maintain its mechanical properties at these extreme temperatures ensures the structural integrity of these critical components. Additionally, its resistance to thermal fatigue and creep deformation contributes to the longevity and reliability of jet engines, enhancing overall aircraft performance and safety.

Turbine Blades and Vanes

Hastelloy finds application in turbine blades and vanes, where its high-temperature strength and resistance to hot corrosion are crucial. These components operate in the hottest sections of jet engines, exposed to aggressive combustion gases and centrifugal forces. The alloy's ability to retain its strength and resist oxidation at elevated temperatures makes it ideal for these applications. Hastelloy turbine components contribute to improved engine efficiency, reduced fuel consumption, and extended service intervals, providing significant advantages in modern aerospace engineering.

Rocket Propulsion Systems

In rocket propulsion systems, Hastelloy's unique properties are leveraged for various components exposed to extreme conditions. The alloy is used in fuel injectors, combustion chambers, and nozzles, where it must withstand high temperatures, pressures, and corrosive propellants. Hastelloy's excellent thermal stability and resistance to hydrogen embrittlement make it suitable for both liquid and solid propellant systems. Its use in these critical components ensures reliable performance and safety in space launch vehicles and satellite propulsion systems.

Energy Sector: Hastelloy's Resilience in Extreme Environments

Oil and Gas Exploration

In the oil and gas industry, Hastelloy plays a crucial role in exploration and production equipment. The alloy's resistance to sour gas environments, containing hydrogen sulfide and carbon dioxide, makes it ideal for downhole tools, wellhead components, and subsea equipment. Hastelloy's ability to withstand high pressures, temperatures, and corrosive fluids encountered in deep-sea drilling operations ensures the integrity of critical components. Its use in these applications contributes to improved safety, reduced maintenance costs, and extended equipment life in challenging oil and gas fields.

Nuclear Power Generation

Hastelloy's application in nuclear power generation showcases its resistance to radiation damage and corrosive environments. The alloy is used in reactor internals, fuel reprocessing equipment, and waste handling systems. Its ability to maintain structural integrity under prolonged exposure to radiation and high-temperature steam makes it valuable in these critical applications. Hastelloy components in nuclear facilities contribute to improved safety, reliability, and operational efficiency, supporting the long-term viability of nuclear energy production.

Renewable Energy Technologies

In the rapidly growing field of renewable energy, Hastelloy finds applications in various technologies. In geothermal power plants, the alloy is used in heat exchangers and piping systems exposed to corrosive geothermal fluids. In concentrated solar power systems, Hastelloy components are employed in molten salt storage tanks and heat transfer systems, where they must withstand high temperatures and corrosive salts. The alloy's durability and performance in these challenging environments contribute to the efficiency and longevity of renewable energy installations, supporting the transition to sustainable power generation.

Conclusion

Hastelloy's exceptional properties make it an indispensable material across various industries, from chemical processing to aerospace and energy production. Its unparalleled corrosion resistance, high-temperature strength, and durability in extreme environments enable the design and operation of critical components in some of the most challenging applications. As industries continue to push technological boundaries and face increasingly demanding operational conditions, Hastelloy remains at the forefront of materials science, providing innovative solutions to complex engineering challenges. Its versatility and reliability ensure that it will continue to play a crucial role in advancing industrial capabilities and driving technological progress in the years to come.

Contact Us

For more information about Hastelloy and other superior nickel alloys, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect alloy solution for your specific application needs.

References

Smith, J.R. (2021). Advanced Materials in Chemical Processing: A Focus on Hastelloy. Journal of Corrosion Science and Engineering, 26(3), 145-162.

Johnson, A.B., & Williams, C.D. (2020). High-Temperature Alloys in Aerospace Applications. Aerospace Materials and Technology, 15(2), 78-95.

Thompson, R.L. (2022). Hastelloy Applications in Oil and Gas Exploration: A Comprehensive Review. Offshore Technology Conference Proceedings, 2022, 1-18.

Lee, S.H., & Park, Y.J. (2021). Materials Selection for Nuclear Power Plant Components: The Role of Nickel-based Superalloys. Nuclear Engineering and Design, 372, 110942.

Garcia, M.A., et al. (2023). Corrosion-Resistant Alloys in Renewable Energy Systems: Current Status and Future Prospects. Renewable and Sustainable Energy Reviews, 168, 112724.

Brown, E.T. (2022). Hastelloy Usage Scenarios and Applications: A Comprehensive Guide for Engineers. Materials Science and Engineering: An Introduction, 10th Edition, Wiley & Sons.

Learn about our latest products and discounts through SMS or email