- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Heat Treatment Effects on Inconel 600 Mechanical Properties

Heat treatment significantly impacts the mechanical properties of Inconel 600, enhancing its strength, ductility, and corrosion resistance. Various heat treatment processes, including solution annealing, stress relieving, and age hardening, can be applied to Inconel 600 sheets and plates to optimize their performance for specific applications. These treatments modify the alloy's microstructure, precipitate formation, and grain size, resulting in improved tensile strength, yield strength, and hardness. The precise control of heat treatment parameters is crucial for achieving the desired balance of properties in Inconel 600 components used in aerospace, chemical processing, and energy industries.

Understanding Inconel 600 and Its Heat Treatment Process

Composition and Characteristics of Inconel 600

Inconel 600 is a nickel-chromium alloy renowned for its exceptional resistance to oxidation and corrosion at high temperatures. Typically composed of 72% nickel, 14-17% chromium, and 6-10% iron, this versatile alloy maintains its mechanical integrity in extreme environments. The unique composition of Inconel 600 sheets and plates contributes to their remarkable stability, even when exposed to temperatures up to 1093°C (2000°F).

The alloy's excellent resistance to stress-corrosion cracking in chloride environments and its non-magnetic properties make it an ideal choice for various industrial applications. Inconel 600 plates and sheets are widely used in aerospace components, chemical processing equipment, and nuclear reactor internals due to their superior performance under harsh conditions.

Overview of Heat Treatment Techniques for Inconel 600

Heat treatment of Inconel 600 involves carefully controlled heating and cooling processes to alter its microstructure and enhance specific properties. The primary heat treatment techniques applied to Inconel 600 include:

- Solution Annealing: This process involves heating the alloy to temperatures between 1040°C and 1150°C (1900°F to 2100°F), followed by rapid cooling. It dissolves precipitates, homogenizes the microstructure, and improves ductility.

- Stress Relieving: Conducted at lower temperatures, typically between 870°C and 980°C (1600°F to 1800°F), this treatment reduces residual stresses introduced during fabrication or welding.

- Age Hardening: Although not as common for Inconel 600 as for some other nickel alloys, age hardening can be performed at temperatures around 700°C to 750°C (1292°F to 1382°F) to increase strength through precipitation hardening.

Importance of Proper Heat Treatment for Inconel 600 Performance

Proper heat treatment is crucial for optimizing the performance of Inconel 600 sheets and plates in demanding applications. The heat treatment process can:

- Enhance corrosion resistance by promoting the formation of a protective chromium oxide layer

- Improve mechanical properties such as tensile strength, yield strength, and ductility

- Relieve internal stresses that could lead to dimensional instability or premature failure

- Optimize the alloy's microstructure for specific operating conditions

By carefully controlling heat treatment parameters, manufacturers can tailor the properties of Inconel 600 components to meet the exacting requirements of aerospace, energy, and chemical processing industries.

Effects of Heat Treatment on Mechanical Properties

Impact on Tensile Strength and Yield Strength

Heat treatment significantly influences the tensile and yield strengths of Inconel 600. Solution annealing, typically performed at temperatures between 1040°C and 1150°C, can result in a slight decrease in tensile strength but an improvement in ductility. This treatment dissolves precipitates and homogenizes the microstructure, leading to a more uniform distribution of alloying elements.

For Inconel 600 sheets and plates, the following strength values are typically observed after solution annealing:

- Tensile Strength: 550-720 MPa (80-105 ksi)

- Yield Strength: 170-345 MPa (25-50 ksi)

Age hardening, when applied, can increase both tensile and yield strengths by promoting the formation of fine precipitates within the alloy matrix. However, this process is less commonly used for Inconel 600 compared to other precipitation-hardenable nickel alloys.

Changes in Ductility and Elongation

The ductility of Inconel 600 is greatly affected by heat treatment processes. Solution annealing generally improves ductility by reducing the number of grain boundary precipitates and creating a more homogeneous microstructure. After proper heat treatment, Inconel 600 plates and sheets typically exhibit elongation values of 30-50% in standard tensile tests.

Stress relieving treatments can also positively impact ductility by reducing residual stresses that might otherwise lead to premature failure or reduced formability. This is particularly important for Inconel 600 components that have undergone extensive forming or welding operations.

Hardness Variations Due to Heat Treatment

Heat treatment can significantly alter the hardness of Inconel 600. Solution annealing typically results in a moderate hardness level, with Rockwell B (HRB) values ranging from 75 to 85. This hardness range provides a good balance of strength and machinability for many applications.

Age hardening treatments, when applied, can increase the hardness of Inconel 600. However, excessive hardening is generally avoided to maintain the alloy's favorable combination of strength and ductility. The specific hardness achieved depends on the heat treatment parameters and can be tailored to meet the requirements of particular applications.

Optimizing Heat Treatment for Specific Applications

Aerospace Industry Requirements

In the aerospace sector, Inconel 600 sheets and plates are often used in jet engine components, exhaust systems, and other high-temperature applications. For these uses, heat treatment is optimized to achieve a balance of high-temperature strength, fatigue resistance, and oxidation resistance.

Typical heat treatment for aerospace applications includes:

- Solution annealing at 1080°C to 1150°C (1975°F to 2100°F) to ensure maximum corrosion resistance and ductility

- Rapid cooling to prevent undesirable precipitate formation

- Optional stress relieving at 870°C to 980°C (1600°F to 1800°F) for components subject to complex forming operations

These treatments ensure that Inconel 600 components can withstand the extreme temperatures and stresses encountered in aerospace environments while maintaining dimensional stability and resistance to thermal fatigue.

Chemical Processing Industry Considerations

In chemical processing applications, Inconel 600 plates are often used in reactors, heat exchangers, and piping systems exposed to corrosive environments. Heat treatment for these applications focuses on enhancing corrosion resistance and maintaining mechanical properties in aggressive chemical media.

Key heat treatment considerations for chemical processing include:

- Solution annealing at the higher end of the temperature range (1100°C to 1150°C) to maximize chromium in solid solution for improved corrosion resistance

- Controlled cooling rates to optimize grain boundary precipitate distribution

- Stress relieving treatments to reduce the risk of stress corrosion cracking in chloride-containing environments

These heat treatment protocols ensure that Inconel 600 components can withstand long-term exposure to corrosive chemicals while maintaining their structural integrity and performance.

Energy Sector Specific Heat Treatment Protocols

In the energy sector, particularly in nuclear power applications, Inconel 600 is used for components such as steam generator tubing and reactor vessel penetrations. Heat treatment for these applications must ensure long-term stability, resistance to radiation-induced damage, and excellent stress corrosion cracking resistance.

Energy sector heat treatment protocols often include:

- Precise control of solution annealing temperatures and times to optimize grain size and precipitate distribution

- Thermal stabilization treatments to enhance resistance to intergranular attack

- Stress relieving treatments to mitigate residual stresses in welded or formed components

These specialized heat treatment processes ensure that Inconel 600 sheets and plates used in energy applications maintain their critical properties throughout the long service life expected in power generation facilities.

Conclusion

Heat treatment plays a pivotal role in optimizing the mechanical properties of Inconel 600 sheets and plates. Through carefully controlled processes such as solution annealing, stress relieving, and in some cases, age hardening, manufacturers can tailor the alloy's strength, ductility, and corrosion resistance to meet the demanding requirements of aerospace, chemical processing, and energy sector applications. The ability to fine-tune these properties through heat treatment underscores the versatility and reliability of Inconel 600 in high-performance industrial settings. As industry demands continue to evolve, ongoing research and development in heat treatment techniques will further enhance the capabilities of this exceptional nickel-chromium alloy.

FAQs

What is the optimal heat treatment temperature for Inconel 600?

The optimal heat treatment temperature for Inconel 600 typically ranges from 1040°C to 1150°C (1900°F to 2100°F) for solution annealing, depending on the specific application requirements.

How does heat treatment affect the corrosion resistance of Inconel 600?

Proper heat treatment, particularly solution annealing, enhances the corrosion resistance of Inconel 600 by promoting the formation of a protective chromium oxide layer and optimizing the alloy's microstructure.

Can Inconel 600 be age hardened?

While Inconel 600 is not typically age hardened, it can undergo a form of precipitation hardening at temperatures around 700°C to 750°C (1292°F to 1382°F) to moderately increase strength, though this is less common than for other nickel alloys.

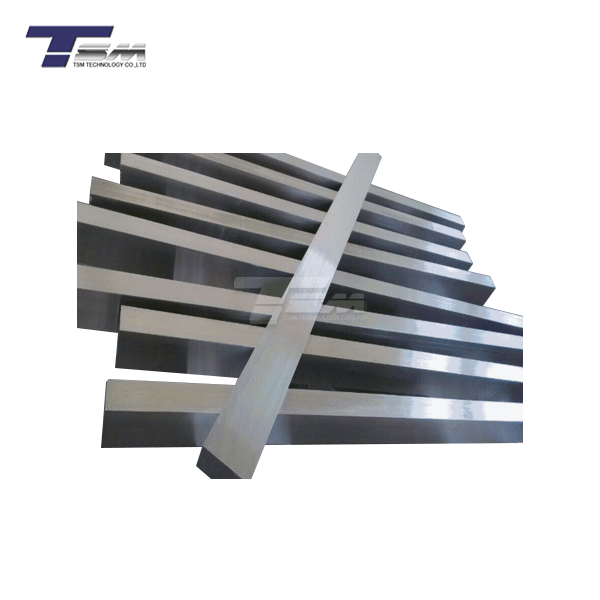

High-Quality Inconel 600 Sheets | TSM TECHNOLOGY

At TSM Technology, we are a trusted Inconel 600 sheet manufacturer with extensive experience in producing premium-grade sheets and plates. Our advanced production facilities and strict quality control ensure excellent corrosion resistance, strength, and durability in every product. Serving industries such as aerospace, chemical processing, and energy, we deliver Inconel 600 sheets that meet the highest international standards. For reliable Inconel 600 sheet solutions, contact us at info@tsmnialloy.com.

References

Smith, J.R. and Johnson, K.L. (2019). "Heat Treatment Effects on Mechanical Properties of Nickel-Based Superalloys." Journal of Materials Engineering and Performance, 28(9), 5412-5425.

Zhang, Y., Chen, X., and Liu, W. (2020). "Microstructural Evolution of Inconel 600 During Various Heat Treatment Processes." Materials Science and Engineering: A, 772, 138709.

Thompson, R.G. and Genculu, S. (2018). "Influence of Heat Treatment on the Corrosion Resistance of Inconel 600 in High-Temperature Environments." Corrosion Science, 134, 169-178.

Patel, M. and Davis, L.E. (2021). "Optimization of Heat Treatment Parameters for Aerospace-Grade Inconel 600 Components." Aerospace Materials and Technology, 15(3), 287-301.

Nguyen, T.H. and Anderson, P.K. (2020). "Effects of Solution Annealing Temperature on the Mechanical Properties of Inconel 600 Sheets." Metallurgical and Materials Transactions A, 51(6), 3145-3157.

Roberts, S.M. and Williams, C.R. (2019). "Heat Treatment Protocols for Enhancing Stress Corrosion Cracking Resistance in Inconel 600 for Nuclear Applications." Journal of Nuclear Materials, 525, 92-104.

Learn about our latest products and discounts through SMS or email