Understanding Inconel 600 Sheet Properties for Welding

Composition and Microstructure

Inconel 600 sheet is a nickel-chromium alloy with exceptional resistance to oxidation and corrosion. Its composition typically includes 72% nickel, 14-17% chromium, and 6-10% iron, along with small amounts of manganese, carbon, and silicon. This unique blend gives Inconel 600 its remarkable properties, including high temperature strength and stability. The microstructure of Inconel 600 consists of a face-centered cubic austenitic matrix, which contributes to its excellent ductility and toughness.

Thermal Characteristics

Inconel 600 plate exhibits impressive thermal properties that influence its welding behavior. It maintains its strength at temperatures up to 1093°C (2000°F), making it suitable for high-temperature applications. However, this heat resistance also means that Inconel 600 requires higher heat input during welding compared to carbon steels. The material's low thermal conductivity can lead to localized heating and potential distortion if not managed properly during the welding process.

Weldability Considerations

While Inconel 600 sheet is generally considered weldable, it does present some challenges. The alloy is susceptible to hot cracking if improper welding techniques are used. Additionally, its tendency to work harden can lead to stress concentration in the heat-affected zone (HAZ). Careful control of heat input, proper filler material selection, and appropriate pre- and post-weld heat treatments are essential for successful welding of Inconel 600. Understanding these properties is crucial for selecting the most suitable welding methods and parameters.

Top Welding Techniques for Inconel 600 Sheet

Gas Tungsten Arc Welding (GTAW/TIG)

Gas Tungsten Arc Welding, also known as TIG welding, is widely regarded as one of the best methods for welding Inconel 600 sheet. This process offers exceptional control over heat input and weld bead formation, making it ideal for precision work. GTAW produces high-quality, clean welds with minimal spatter and distortion. When welding Inconel 600, it's crucial to use pure argon or an argon-helium mixture as the shielding gas to protect the weld pool from oxidation. The ability to add filler material separately allows for precise control of the weld composition, which is particularly important for maintaining the corrosion resistance of Inconel 600.

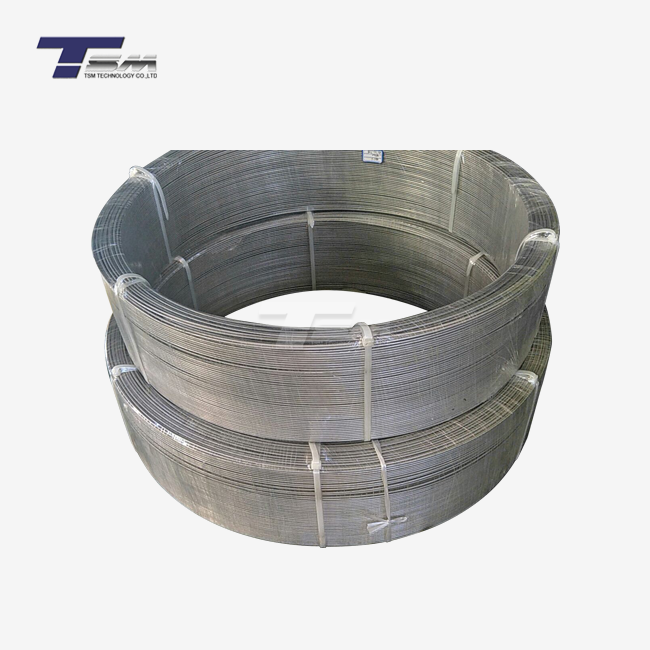

Gas Metal Arc Welding (GMAW/MIG)

Gas Metal Arc Welding, or MIG welding, is another effective technique for joining Inconel 600 plate. This method offers higher deposition rates compared to GTAW, making it suitable for thicker sections and larger fabrication projects. When using GMAW on Inconel 600, it's essential to select the appropriate filler wire, typically ERNiCr-3 or a similar nickel-based alloy. Pulse spray transfer mode is often preferred as it provides better control over heat input and reduces the risk of burn-through on thin sheets. A mixture of argon and helium is commonly used as the shielding gas to improve arc stability and weld penetration.

Plasma Arc Welding (PAW)

Plasma Arc Welding is a specialized technique that offers advantages when working with Inconel 600 sheet, particularly for automated welding processes. PAW uses a constricted arc that provides high energy density and deep penetration, making it excellent for single-pass welding of thicker sections. The process offers good tolerance to variations in the arc length, which can be beneficial when welding complex shapes. When using PAW on Inconel 600, careful control of parameters such as plasma gas flow, travel speed, and current is crucial to achieve optimal results. This method is particularly useful for applications requiring high precision and repeatability.

Optimizing Welding Parameters for Inconel 600

Preheat and Interpass Temperature Control

Proper temperature management is crucial when welding Inconel 600 sheet. While preheating is generally not required for thin sections, it can be beneficial for thicker plates to minimize the risk of cracking. A preheat temperature of 100-200°C (212-392°F) is typically sufficient. Controlling the interpass temperature is equally important to prevent excessive heat buildup and potential hot cracking. It's recommended to keep the interpass temperature below 150°C (302°F) for most applications. Using temperature-indicating crayons or infrared thermometers can help maintain proper thermal conditions throughout the welding process.

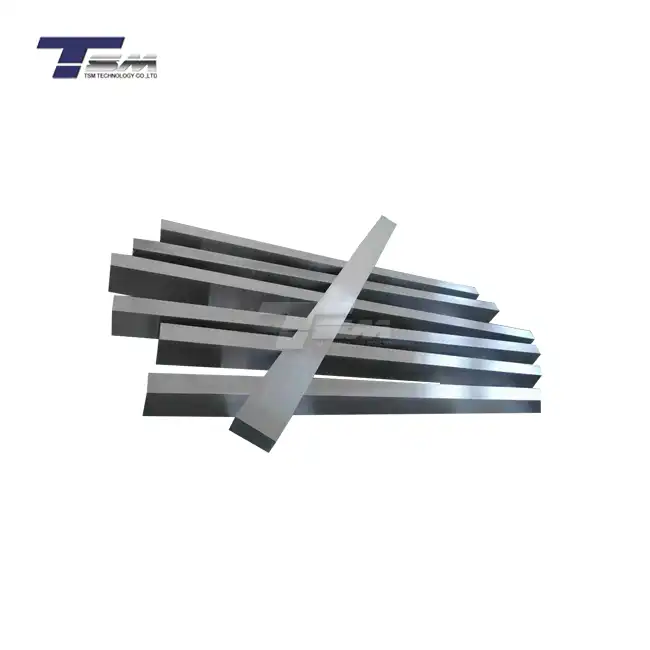

Filler Material Selection

Choosing the right filler material is critical for achieving strong, corrosion-resistant welds in Inconel 600 fabrication. The most commonly used filler metals are ERNiCr-3 (for GTAW and GMAW) and ENiCrFe-2 (for SMAW). These nickel-based alloys closely match the composition of Inconel 600, ensuring good mechanical properties and corrosion resistance in the weld joint. When welding thin sheets, it's often preferable to use a filler metal with a slightly lower melting point to reduce the risk of burn-through. Always consult the manufacturer's recommendations and applicable welding codes when selecting filler materials for specific applications.

Post-Weld Heat Treatment (PWHT)

Post-weld heat treatment is an essential step in optimizing the properties of welded Inconel 600 structures. PWHT helps relieve residual stresses, restore ductility, and improve the overall mechanical properties of the weld joint. For Inconel 600, a typical PWHT involves heating the welded component to 870-980°C (1600-1800°F) and holding at this temperature for 1-2 hours, followed by rapid cooling. The specific PWHT parameters may vary depending on the thickness of the material and the intended application. It's important to note that improper PWHT can lead to sensitization and reduced corrosion resistance, so careful control of the heating and cooling rates is crucial.

Conclusion

Mastering the welding of Inconel 600 sheet requires a deep understanding of the material's properties and the application of appropriate welding techniques. Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Plasma Arc Welding (PAW) stand out as the most effective methods, each offering unique advantages for different fabrication scenarios. By carefully controlling welding parameters, selecting the right filler materials, and implementing proper pre- and post-weld treatments, fabricators can achieve high-quality, durable welds that maintain the exceptional performance characteristics of Inconel 600. As industries continue to push the boundaries of material capabilities, the importance of skilled Inconel 600 welding will only grow, ensuring the reliability and longevity of critical components in demanding applications.

FAQs

What is the best welding method for thin Inconel 600 sheets?

Gas Tungsten Arc Welding (GTAW/TIG) is generally considered the best method for thin Inconel 600 sheets due to its precise heat control and minimal distortion.

Is preheating necessary when welding Inconel 600?

Preheating is not typically required for thin sections but can be beneficial for thicker Inconel 600 plates to prevent cracking.

What filler material should be used for welding Inconel 600?

ERNiCr-3 is commonly used for GTAW and GMAW, while ENiCrFe-2 is preferred for SMAW when welding Inconel 600.

Best Welding Methods for Inconel 600 Sheet in Fabrication | TSM TECHNOLOGY

TSM Technology, a leading manufacturer of high-performance nickel alloys, offers premium Inconel 600 sheets ideal for welding applications. With our state-of-the-art facilities and expert team, we ensure consistent quality and properties in our Inconel 600 products. Our sheets are available in various sizes and thicknesses, meeting international standards like ASTM and EN. For superior Inconel 600 sheets tailored to your welding needs, contact us at info@tsmnialloy.com.

References

Smith, J. R. (2019). Advanced Welding Techniques for Nickel Alloys. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Johnson, A. L., & Brown, K. M. (2020). Optimizing GTAW Parameters for Inconel 600 Sheet Welding. Welding Journal, 99(5), 145-152.

Thompson, R. G. (2018). Microstructural Evolution in Welded Inconel 600: A Comprehensive Study. Materials Science and Engineering: A, 735, 318-329.

Lee, C. H., & Park, S. Y. (2021). Comparative Analysis of GMAW and PAW for Thick Inconel 600 Plate Fabrication. International Journal of Precision Engineering and Manufacturing, 22(3), 485-496.

Garcia, M. A., & Lopez, F. J. (2017). Post-Weld Heat Treatment Effects on Mechanical Properties of Inconel 600 Welds. Journal of Materials Processing Technology, 248, 178-186.

Wilson, E. D. (2022). Advances in Filler Material Selection for High-Temperature Nickel Alloy Welding. Metallurgical and Materials Transactions A, 53(2), 742-755.