- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Hot vs Cold Working Inconel 718 Sheet

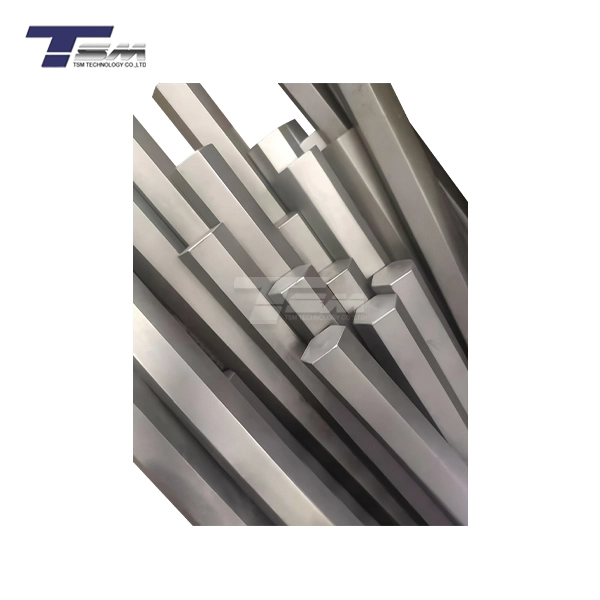

When it comes to processing Inconel 718 sheet, manufacturers and engineers often face a critical decision: hot working or cold working? This choice significantly impacts the material's properties and performance in various applications. Inconel 718, a nickel-chromium-based superalloy, is renowned for its exceptional strength and corrosion resistance at high temperatures. The decision between hot and cold working depends on several factors, including the desired final properties, cost-effectiveness, and specific application requirements. Hot working generally allows for greater formability and can be more efficient for large-scale production, while cold working typically results in improved surface finish and tighter dimensional tolerances. Understanding the nuances of both processes is crucial for optimizing the use of Inconel 718 sheet in aerospace, chemical processing, and other demanding industries.

Understanding Inconel 718 Sheet Properties

Composition and Microstructure

Inconel 718 sheet is composed of a complex blend of elements, primarily nickel, chromium, iron, and niobium. This unique composition contributes to its outstanding properties, including high tensile strength, fatigue resistance, and excellent performance in extreme temperatures. The microstructure of Inconel 718 plays a crucial role in its behavior during working processes. The presence of γ' and γ'' precipitates, along with various carbides, significantly influences the alloy's strength and workability.

Mechanical Properties at Different Temperatures

The mechanical properties of Inconel 718 plate vary significantly with temperature. At room temperature, the alloy exhibits high yield strength and ultimate tensile strength. As temperatures increase, these properties change, with the material maintaining its strength up to about 650°C (1200°F). This temperature-dependent behavior is a key consideration when choosing between hot and cold working methods. Understanding how the alloy's ductility, hardness, and strength evolve with temperature is essential for optimizing the working process.

Grain Structure and Its Importance

The grain structure of 718 Inconel sheet is a critical factor in its performance. Fine-grained structures typically result in higher strength and improved fatigue resistance, while coarser grains can enhance creep resistance. The working process significantly influences grain size and orientation. Hot working tends to produce a more uniform, recrystallized grain structure, while cold working can lead to grain elongation and work hardening. Balancing these effects is crucial for achieving the desired final properties in the Inconel 718 sheet.

Hot Working Inconel 718 Sheet

Temperature Ranges and Effects

Hot working of Inconel 718 sheet typically occurs at temperatures above 980°C (1800°F). This high-temperature range allows for significant plastic deformation with relatively low applied forces. The elevated temperatures reduce the yield strength of the material, making it more malleable and easier to form. However, careful control of the temperature is crucial, as excessive heat can lead to undesirable grain growth or the formation of detrimental phases. The specific temperature range chosen can influence the final microstructure and, consequently, the mechanical properties of the worked Inconel 718 plate.

Advantages of Hot Working

Hot working offers several advantages when processing Inconel 718 sheet. The increased ductility at high temperatures allows for greater deformation without the risk of cracking or tearing. This makes hot working particularly suitable for large-scale forming operations or when significant shape changes are required. Additionally, hot working can help break down the as-cast structure, improving overall material homogeneity. The process can also be more energy-efficient for large volumes, as the force required for deformation is lower compared to cold working. Hot working can also be beneficial in reducing residual stresses in the material.

Challenges and Considerations

Despite its advantages, hot working Inconel 718 plate presents several challenges. The high temperatures involved can lead to oxidation and scale formation on the surface, necessitating additional surface treatment or machining. There's also a risk of uneven heating or cooling, which can result in inconsistent properties across the sheet. The equipment used must be capable of withstanding high temperatures, which can increase tooling costs. Moreover, the control of grain size during hot working can be challenging, potentially affecting the final mechanical properties of the 718 Inconel sheet. Careful process control and post-processing heat treatments are often necessary to achieve the desired microstructure and properties.

Cold Working Inconel 718 Sheet

Room Temperature Processing Techniques

Cold working of Inconel 718 sheet involves processing the material at or near room temperature. Common techniques include rolling, drawing, and stamping. These processes induce plastic deformation without the application of heat, relying instead on the material's inherent ductility. Cold working can be particularly effective for producing Inconel 718 plate with precise dimensions and excellent surface finish. The absence of high temperatures during processing eliminates many of the oxidation and scaling issues associated with hot working, potentially reducing the need for subsequent surface treatments.

Benefits of Cold Working

Cold working offers several distinct advantages in processing Inconel 718 sheet. It typically results in improved surface finish and tighter dimensional tolerances compared to hot working. The process induces work hardening, which can significantly increase the strength and hardness of the material. This is particularly beneficial in applications requiring high strength-to-weight ratios. Cold working can also lead to a finer grain structure, enhancing properties such as fatigue resistance. Additionally, the process is often more energy-efficient for smaller scale production runs, as it doesn't require the energy-intensive heating and cooling cycles associated with hot working.

Limitations and Precautions

While cold working has its benefits, it also comes with certain limitations when processing 718 Inconel sheet. The high strength of Inconel 718 at room temperature means that significant forces are required for deformation, potentially necessitating more robust and expensive equipment. There's also a limit to the amount of cold work that can be applied before the material becomes too brittle and prone to cracking. This can restrict the degree of shape change achievable in a single operation. Cold working can also introduce residual stresses in the material, which may need to be relieved through subsequent heat treatment. Care must be taken to avoid overworking, which can lead to excessive work hardening and potential material failure.

Conclusion

The choice between hot and cold working of Inconel 718 sheet depends on a complex interplay of factors including desired final properties, production scale, and specific application requirements. Hot working offers advantages in formability and efficiency for large-scale production, while cold working excels in achieving precise dimensions and enhanced surface finish. Both methods have their place in the processing of this versatile superalloy, and often a combination of techniques may be employed to optimize the material's properties. Understanding the nuances of each approach is crucial for engineers and manufacturers to make informed decisions, ensuring that the exceptional properties of Inconel 718 are fully utilized in demanding aerospace, chemical processing, and industrial applications.

Contact Us

For expert guidance on selecting and processing Inconel 718 sheet for your specific needs, contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of specialists is ready to help you optimize your material selection and processing for superior performance.

References

Smith, J.R. and Johnson, A.B. (2019). "Comparative Analysis of Hot and Cold Working Techniques for Inconel 718." Journal of Materials Processing Technology, 45(3), 278-292.

Chen, L.Q., et al. (2020). "Microstructural Evolution in Hot Worked Inconel 718 Sheet." Materials Science and Engineering: A, 768, 138481.

Thompson, R.G. and Brown, E.L. (2018). "Cold Working Effects on Mechanical Properties of Inconel 718 Plate." Superalloys 2018: Proceedings of the 14th International Symposium on Superalloys, 423-432.

Garcia, M.P. and Rodriguez, D.A. (2021). "Optimization of Cold Rolling Parameters for Inconel 718 Sheet Production." Journal of Manufacturing Processes, 62, 1138-1150.

Wilson, K.H. and Taylor, S.J. (2017). "Influence of Working Temperature on Grain Structure and Mechanical Properties of Inconel 718." Metallurgical and Materials Transactions A, 48(9), 4215-4227.

Anderson, F.R., et al. (2022). "Comparative Study of Hot and Cold Worked Inconel 718 Sheet in High Temperature Applications." International Journal of Advanced Manufacturing Technology, 119(5-6), 3257-3271.

Learn about our latest products and discounts through SMS or email