Understanding Nickel 201's Alkali Resistance Properties

Chemical Composition and Its Impact

The exceptional alkali resistance of Nickel 201 plate primarily stems from its high purity, containing at least 99.0% nickel. This high nickel concentration allows the alloy to form a stable and adherent passive oxide film when exposed to alkaline environments. The protective layer acts as a strong chemical barrier that minimizes further metal dissolution, thereby reducing corrosion rates. This inherent stability enables Nickel 201 to perform reliably in the presence of strong alkalis, making it a preferred material for caustic soda production and other chemical processing applications.

Corrosion Mechanism in Alkaline Solutions

When Nickel 201 is exposed to concentrated alkaline solutions, a thin, uniform oxide film-mainly composed of nickel hydroxide-forms on its surface. This passive film prevents direct contact between the base metal and the corrosive environment, effectively hindering electrochemical reactions that cause deterioration. The protective layer's stability increases with the concentration of alkali, allowing Nickel 201 to resist aggressive attack even under prolonged exposure. This self-regenerating oxide mechanism ensures long-term durability and consistent corrosion protection in highly caustic industrial environments.

Temperature Effects on Alkali Resistance

Although the Nickel 201 plate shows outstanding alkali resistance at ambient temperatures, thermal effects can influence its corrosion performance. As the temperature rises, diffusion and reaction rates accelerate, potentially increasing the corrosion rate. However, Nickel 201 maintains excellent structural integrity and chemical stability even in 70% sodium hydroxide solutions at temperatures up to 315°C (600°F). This high-temperature resilience makes it an ideal choice for applications such as caustic evaporators, heat exchangers, and reactors operating under extreme thermal and chemical conditions.

Applications Leveraging Nickel 201's Alkali Resistance

Chemical Processing Equipment

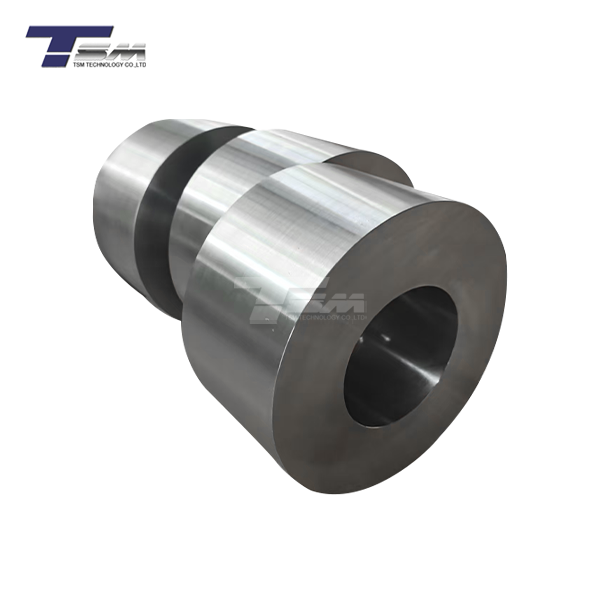

Nickel 201 plate is widely recognized as a preferred material for chemical processing equipment due to its superior resistance to concentrated alkaline environments. It is extensively used in the fabrication of reactors, heat exchangers, tanks, and pipelines that handle caustic or corrosive chemical media. The alloy's high purity and ability to form a protective oxide layer provide long-term durability and minimal corrosion, even under continuous exposure to strong alkalis. These characteristics significantly reduce maintenance costs and enhance the overall reliability and efficiency of chemical production systems.

Caustic Evaporators and Storage Tanks

In the manufacturing and storage of caustic soda (sodium hydroxide), Nickel 201 plate plays an essential role in ensuring equipment safety and performance. Its ability to maintain mechanical strength and corrosion resistance under high concentrations of NaOH and elevated temperatures makes it ideal for constructing evaporators, condensers, and storage tanks. These components must operate reliably under harsh conditions, and Nickel 201’s stability minimizes the risk of stress cracking or leakage. As a result, it provides extended service life and consistent operational safety in alkali-handling environments.

Electrochemical Processes

Nickel 201's excellent resistance to alkali and high electrical conductivity make it particularly suitable for use in electrochemical systems, including chlor-alkali production and alkaline electrolysis. It is commonly used in electrodes, cell liners, and conductive components that require both chemical stability and electrical efficiency. The alloy's resistance to corrosion under prolonged exposure to alkaline electrolytes ensures dependable performance and reduced downtime. By maintaining high conductivity and surface integrity, Nickel 201 supports efficient energy transfer and long-term operational stability in demanding industrial electrochemical processes.

Factors Influencing Nickel 201's Alkali Resistance Performance

Surface Condition and Preparation

The surface condition of Nickel 201 plate significantly affects its ability to resist alkaline corrosion. Smooth, well-prepared surfaces facilitate the formation of a uniform and adherent passive oxide layer that protects the metal from aggressive alkali attack. Techniques such as passivation, electropolishing, or mechanical polishing can enhance surface quality and corrosion resistance. Regular cleaning and maintenance prevent buildup of residues or contaminants that could compromise the protective film. A properly treated surface ensures stable performance, improved longevity, and consistent alkali resistance in demanding chemical environments.

Stress and Mechanical Factors

Although Nickel 201 is known for its outstanding resistance to alkalis, mechanical stress and strain can influence its corrosion performance. Excessive tensile stresses, either from fabrication processes or operational conditions, may lead to stress corrosion cracking (SCC) when combined with certain impurities. To minimize these risks, manufacturers implement stress-relief annealing, careful welding practices, and optimized component design. Reducing sharp edges, residual stresses, and mechanical deformation helps preserve the alloy's structural integrity, ensuring reliable operation in concentrated alkaline solutions over extended service periods.

Presence of Impurities and Contaminants

The chemical purity of the alkaline environment plays a decisive role in maintaining Nickel 201's superior corrosion resistance. Trace impurities such as sulfur, chlorides, or oxidizing agents can disrupt the stability of the protective oxide film, leading to localized pitting or accelerated corrosion. Continuous monitoring of solution composition and implementing filtration or purification processes are essential to control contamination. Maintaining clean operating conditions and minimizing impurity levels ensure that Nickel 201 retains its exceptional alkali resistance and mechanical stability even under highly caustic and high-temperature conditions.

Conclusion

Nickel 201 plate demonstrates exceptional resistance to concentrated alkali, making it an invaluable material for various industrial applications involving harsh alkaline environments. Its ability to withstand up to 70% sodium hydroxide at temperatures as high as 315°C (600°F) is a testament to its superior corrosion resistance properties. By understanding the factors that influence its performance and implementing proper design and maintenance practices, engineers and industry professionals can leverage Nickel 201's unique characteristics to ensure long-lasting and reliable equipment in alkaline processing applications.

FAQs

What is the maximum concentration of alkali that Nickel 201 plate can resist?

Nickel 201 plate can resist up to 70% sodium hydroxide (NaOH) at temperatures as high as 315°C (600°F).

What are the key features of Nickel 201 plate?

Nickel 201 plate features high purity (min. 99.0% Ni), excellent corrosion resistance, superior thermal and electrical conductivity, good ductility and formability, and non-magnetic properties.

What are some common applications for Nickel 201 plate?

Nickel 201 plates are commonly used in chemical processing equipment, food preparation vessels, pharmaceutical reactors, electronic components, and heat exchangers.

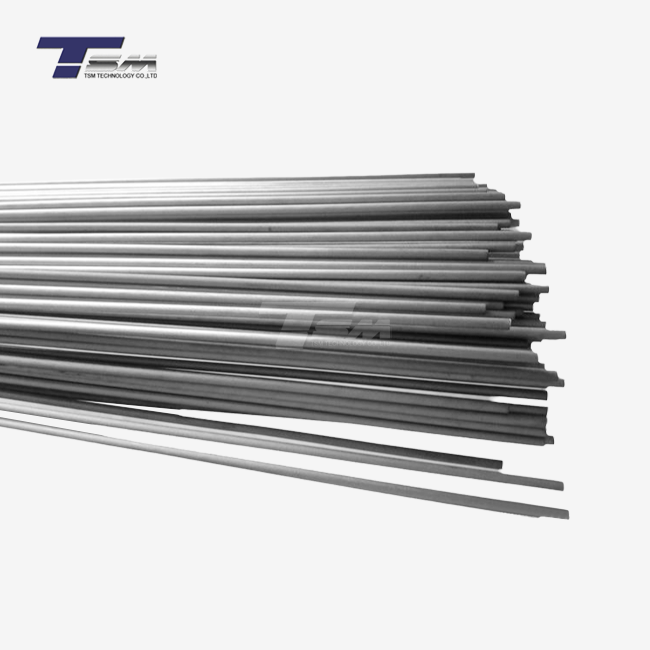

Why Choose TSM Technology for Your Nickel 201 Plate Needs?

TSM Technology, a leading Nickel 201 plate manufacturer and supplier, offers superior quality products that excel in concentrated alkali resistance. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure consistent quality and performance. Our Nickel 201 plates, available in thicknesses from 5-150 mm and widths of 1000-2500 mm, comply with ASTM B162, ASME SB162, and DIN 17750 standards. Trust TSM Technology for your alkali-resistant Nickel 201 plate needs. Contact us at info@tsmnialloy.com for inquiries or to request a free sample.