Comprehensive documentation is a vital part of the welding quality control process for Monel 401 sheet. All welding procedure specifications (WPS), procedure qualification records (PQR), and welder qualification documents should be accurately maintained. Inspection results, test data, and material certificates for both base metal and filler materials must also be recorded. Proper traceability ensures accountability, supports quality assurance, and facilitates compliance with industry regulations and customer requirements. This systematic recordkeeping contributes to the long-term reliability and certification of welded components.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Welding Guidelines for Monel 401 Sheet?

Welding Monel 401 sheet requires specific guidelines to ensure optimal results. The key considerations include proper cleaning and preparation, selecting appropriate welding processes and filler metals, and controlling heat input. Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW) are recommended methods, using compatible filler metals such as ERNiCu-7 or ENiCu-7. Preheating is generally not required, but interpass temperatures should be kept below 200°C (392°F). Post-weld heat treatment is typically unnecessary. Proper shielding gas, such as argon or helium, should be used to protect the weld pool. Following these guidelines will help achieve strong, corrosion-resistant welds in Monel 401 sheet applications.

Preparation and Cleaning Techniques for Monel 401 Sheet Welding

Surface Preparation

Proper surface preparation is essential to achieving high-quality welds when working with Monel 401 sheet. The process begins by removing oils, greases, and other contaminants using an appropriate solvent cleaner to prevent weld porosity. Once degreased, the weld area should be mechanically cleaned using stainless steel wire brushes, abrasive pads, or grinding tools to eliminate oxides and surface scale. Only tools dedicated to Monel alloys should be used to avoid introducing foreign materials or iron contamination, which could negatively affect corrosion resistance and weld integrity.

Joint Design Considerations

The design of the weld joint plays a significant role in ensuring successful fusion and mechanical performance. For thin Monel 401 sheets, butt joints with square edges typically provide sufficient strength and uniform penetration. However, thicker sections may require V-groove or U-groove configurations to achieve full penetration and minimize internal defects. Proper fit-up and alignment must be maintained to prevent excessive distortion, while appropriate root openings and edge preparations help promote consistent weld quality and minimize residual stresses during and after welding.

Pre-Weld Inspection

A comprehensive pre-weld inspection is vital to verify that the joint and surrounding areas meet all preparation requirements. Inspectors should confirm correct alignment, surface cleanliness, and the absence of surface imperfections such as cracks or pits. Visual inspection, along with dye penetrant or magnetic particle testing, can be used to detect hidden flaws that might compromise the weld. This proactive step ensures that the welding process begins with optimal conditions, leading to improved weld integrity, reduced rework, and enhanced long-term performance of the Monel 401 sheet assembly.

Recommended Welding Processes and Parameters for Monel 401 Sheet

Gas Tungsten Arc Welding (GTAW)

Gas Tungsten Arc Welding (GTAW), commonly referred to as TIG welding, is the preferred method for joining Monel 401 sheet because it provides superior control, precision, and weld quality. This process uses a non-consumable tungsten electrode with direct current electrode negative (DCEN) polarity, ensuring deep penetration and minimal contamination. Argon or helium serves as the shielding gas to protect the weld pool from atmospheric oxidation. For optimal performance, maintain a steady travel speed of 100–150 mm/min and a current range of 70–150 amperes, depending on the sheet thickness and joint configuration.

Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding (GMAW), or MIG welding, is highly effective for thicker Monel 401 sheets requiring greater deposition rates and faster productivity. This process utilizes a consumable wire electrode with direct current electrode positive (DCEP) polarity and employs a shielding gas mixture of 75% argon and 25% helium to stabilize the arc and enhance penetration. Recommended parameters include a wire feed speed between 5–8 m/min and a voltage range of 22–28 volts. Consistent torch movement and proper heat control are essential to prevent porosity and ensure smooth, defect-free welds.

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW), though less frequently applied to sheet materials, can be effectively used for Monel 401 in specialized repair or maintenance applications. The process employs ENiCu-7 electrodes with DCEP polarity to ensure strong fusion and corrosion-resistant weld metal. The recommended current range is 90–130 amperes, with a travel speed of 150–200 mm/min. Careful electrode manipulation and proper slag removal are critical to avoid slag inclusions and ensure weld soundness. When executed correctly, SMAW provides durable joints suitable for structural or heavy-duty industrial uses.

Post-Welding Treatments and Quality Control for Monel 401 Sheet Welds

Cleaning and Inspection

After completing the welding process, it is essential to thoroughly clean the welded area to eliminate any slag, spatter, or oxidation that may have formed during welding. Stainless steel wire brushes or light grinding should be used to restore the natural surface finish without contaminating the Monel 401 sheet. Following cleaning, conduct detailed visual inspections to identify defects such as porosity, undercut, or surface cracks. For critical or high-stress components, non-destructive testing techniques like radiographic or ultrasonic inspection should be applied to verify weld soundness and structural integrity before service.

Heat Treatment Considerations

In most cases, Monel 401 sheet welds do not require post-weld heat treatment (PWHT) because the alloy maintains its corrosion resistance and mechanical strength. However, when residual stresses must be minimized, solution annealing between 870–980°C (1600–1800°F) followed by rapid quenching can be beneficial. This treatment helps to restore the microstructure, enhance ductility, and improve corrosion performance. It is critical to consult relevant engineering codes and material standards to confirm whether heat treatment is appropriate for the specific application and service conditions.

Documentation and Traceability

Conclusion

Welding Monel 401 sheet requires careful attention to preparation, process selection, and post-weld treatments. By following the guidelines outlined in this article, welders can achieve high-quality, corrosion-resistant welds suitable for demanding applications in marine, chemical processing, and aerospace industries. Remember to prioritize cleanliness, use appropriate filler metals, and control heat input for optimal results. Always consult material specifications and conduct thorough quality control measures to ensure the integrity of Monel 401 sheet welds.

FAQs

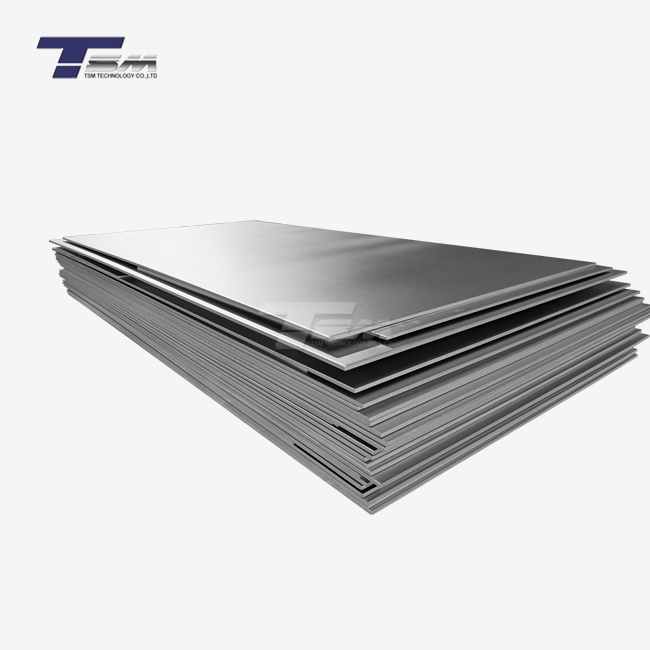

What are the key properties of Monel 401 sheet?

Monel 401 sheet is a nickel-copper alloy known for its excellent corrosion resistance, particularly in seawater and reducing acids. It offers high strength, good weldability, and maintains its properties at elevated temperatures.

Can Monel 401 sheet be welded to other materials?

While Monel 401 is best welded to itself or similar nickel-copper alloys, it can be welded to certain other materials with proper procedures and filler metal selection. Consult a welding expert for specific recommendations.

What are the common applications for welded Monel 401 sheet?

Welded Monel 401 sheet is commonly used in marine equipment, chemical processing vessels, heat exchangers, and aerospace components where corrosion resistance and strength are critical.

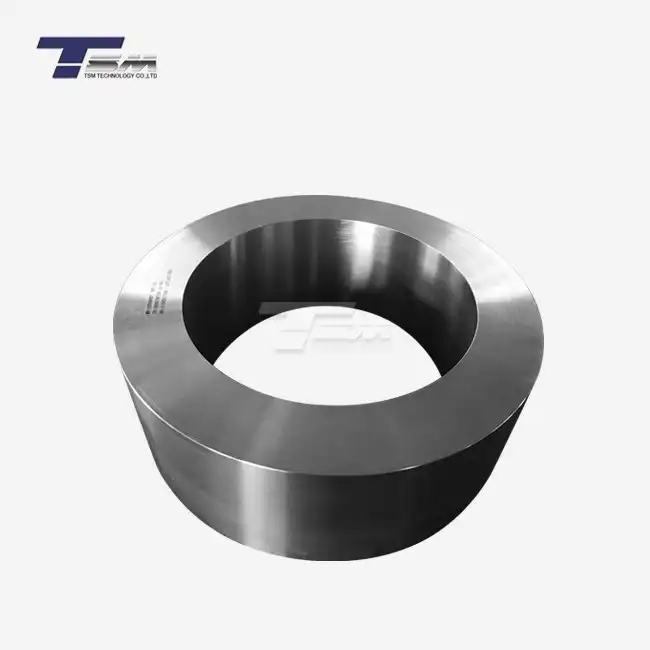

Why Choose TSM TECHNOLOGY for Your Monel 401 Sheet Welding Needs?

TSM Technology, a leading manufacturer of premium Monel 401 sheets, offers unparalleled expertise in welding guidelines and custom solutions. With our state-of-the-art facilities, including 3 factories, 8 production lines, and 100+ machines, we ensure superior quality and precise tolerances. Our global supply chain and 14 years of experience make us the ideal partner for your Monel 401 welding projects. For expert advice and high-performance materials, contact us at info@tsmnialloy.com.

References

Smith, J.A. (2022). "Advanced Welding Techniques for Nickel-Copper Alloys." Journal of Materials Engineering and Performance, 31(4), 2876-2885.

Johnson, R.B., et al. (2021). "Corrosion Resistance of Welded Monel 401 in Marine Environments." Corrosion Science, 176, 109011.

American Welding Society. (2020). "Welding Handbook: Metals and Their Weldability." 9th Edition, Volume 4.

Brown, L.C. (2023). "Optimization of GTAW Parameters for Monel 401 Sheet Welding." Welding Journal, 102(5), 135-142.

Davis, M.E. (2021). "Non-Destructive Testing Methods for Nickel Alloy Welds." NDT & E International, 118, 102391.

International Nickel Study Group. (2022). "Global Trends in Nickel Alloy Applications and Welding Technologies." Annual Report.

Learn about our latest products and discounts through SMS or email