The Science Behind Nickel Alloy Plates' Corrosion Resistance

Composition and Microstructure

The exceptional corrosion resistance of nickel alloy plate stems from its unique composition and microstructure. These alloys typically contain a high percentage of nickel, often combined with chromium, molybdenum, and other elements. This carefully engineered blend creates a material with superior resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

The microstructure of nickel alloy plates plays a crucial role in their corrosion-resistant properties. The face-centered cubic crystal structure of nickel provides excellent ductility and toughness, while the addition of alloying elements enhances the material's strength and resistance to environmental degradation. This combination results in a robust and durable material capable of withstanding the harsh conditions encountered in marine environments.

Passive Film Formation

One of the key mechanisms behind the corrosion resistance of nickel alloy plates is the formation of a passive film on their surface. When exposed to oxygen, the alloy quickly forms a thin, adherent oxide layer that acts as a barrier against further corrosion. This passive film is self-healing, meaning that if it becomes damaged, it rapidly reforms to continue protecting the underlying metal.

The passive film on nickel alloy plates is particularly effective in marine environments due to its stability in chloride-containing solutions. This property is crucial for resisting the corrosive effects of seawater, which contains high levels of chloride ions. The film's ability to remain intact under these conditions significantly contributes to the alloy's long-term durability in marine applications.

Electrochemical Properties

The electrochemical properties of nickel alloy plates further enhance their corrosion resistance in marine settings. These alloys exhibit a high resistance to galvanic corrosion, which can occur when dissimilar metals are in contact in an electrolyte solution like seawater. The noble electrochemical potential of nickel alloys helps prevent them from becoming anodic in galvanic couples, reducing the risk of accelerated corrosion.

Additionally, nickel alloy plates demonstrate excellent resistance to localized forms of corrosion, such as pitting and crevice corrosion. This resistance is attributed to the alloy's ability to maintain a stable passive film even in the presence of aggressive ions found in marine environments. The combination of these electrochemical properties makes nickel alloy plates highly resistant to various corrosion mechanisms encountered in marine applications.

Applications of Nickel Alloy Plate in Marine Environments

Shipbuilding and Naval Architecture

In the shipbuilding industry, nickel alloy plates find extensive use due to their superior corrosion resistance and mechanical properties. These alloys are employed in critical components such as propeller shafts, pump casings, and valve bodies, where exposure to seawater is constant. The use of nickel alloy plates in these applications ensures long-term reliability and reduces the need for frequent maintenance or replacement.

Naval architects also utilize nickel alloy plates in the construction of specialized vessels, such as research ships and deep-sea exploration vehicles. The material's ability to withstand high pressures and resist corrosion at great depths makes it invaluable for these demanding applications. Furthermore, nickel alloy plates contribute to the overall structural integrity of marine vessels, enhancing their safety and longevity in challenging oceanic conditions.

Offshore Platforms and Structures

Offshore oil and gas platforms represent another significant application area for nickel alloy plates. These structures are exposed to some of the most corrosive environments, combining saltwater spray, high humidity, and often extreme temperatures. Nickel alloy plates are used in various components of these platforms, including structural supports, piping systems, and process equipment.

The corrosion resistance of nickel alloy plates is particularly crucial in areas where failure could lead to catastrophic consequences, such as in subsea manifolds and wellhead components. By using these alloys, offshore operators can ensure the long-term integrity of their installations, reduce maintenance costs, and minimize the risk of environmental incidents.

Marine Energy Systems

The growing field of marine renewable energy also benefits from the properties of nickel alloy plates. In tidal and wave energy systems, components are subjected to constant exposure to seawater and cyclic loading. Nickel alloy plates are used in the construction of turbine blades, support structures, and power transmission components in these systems.

The corrosion resistance of nickel alloy plates ensures that these marine energy installations can operate efficiently for extended periods without degradation. This longevity is crucial for the economic viability of marine renewable energy projects, as it reduces the need for frequent maintenance interventions in challenging offshore environments.

Advantages of Using Nickel Alloy Plate in Marine Applications

Long-Term Cost-Effectiveness

While the initial cost of nickel alloy plates may be higher compared to some alternative materials, their long-term cost-effectiveness in marine applications is significant. The exceptional corrosion resistance of these alloys translates into reduced maintenance requirements and longer service life for components and structures. This durability results in lower lifecycle costs, as the frequency of repairs, replacements, and associated downtime is minimized.

Furthermore, the use of nickel alloy plates can lead to savings in protective coatings and cathodic protection systems. The inherent corrosion resistance of the material often eliminates or reduces the need for additional protective measures, simplifying maintenance procedures and reducing ongoing operational costs in marine environments.

Enhanced Safety and Reliability

Safety is paramount in marine operations, and the use of nickel alloy plates contributes significantly to this aspect. The material's resistance to corrosion-induced failure enhances the overall reliability of marine structures and equipment. This reliability is crucial in preventing accidents, leaks, or structural failures that could have severe consequences for human safety and the environment.

In critical applications such as offshore oil and gas production, the use of nickel alloy plates in key components provides an additional layer of safety. The material's ability to maintain its integrity under extreme conditions ensures that safety systems and containment structures remain effective throughout their intended service life, mitigating risks associated with equipment failure in harsh marine environments.

Environmental Benefits

The durability and corrosion resistance of nickel alloy plates also contribute to environmental sustainability in marine applications. By extending the lifespan of marine structures and equipment, these alloys help reduce the demand for raw materials and energy associated with frequent replacements. This longevity translates into a lower environmental footprint over the lifecycle of marine installations.

Additionally, the corrosion resistance of nickel alloy plates helps prevent leaks and failures that could lead to environmental contamination. In applications such as offshore oil and gas production or chemical transportation, the use of these alloys in critical components provides an extra layer of protection against spills or releases that could harm marine ecosystems.

Conclusion

Nickel alloy plate emerges as an indispensable material for marine applications, owing to its exceptional corrosion resistance. Its unique composition, passive film formation, and electrochemical properties make it ideal for withstanding the harsh, corrosive conditions of marine environments. From shipbuilding and offshore platforms to marine energy systems, nickel alloy plates offer long-term cost-effectiveness, enhanced safety, and environmental benefits. As marine industries continue to evolve and face new challenges, the role of nickel alloy plates in ensuring durability, reliability, and sustainability remains crucial. Their ability to combat corrosion effectively positions them as a key material in advancing marine technology and protecting our oceans.

FAQs

What makes nickel alloy plates particularly suitable for marine use?

Nickel alloy plates are ideal for marine use due to their exceptional corrosion resistance, ability to form a protective passive film, and stability in chloride-containing environments like seawater.

How do nickel alloy plates contribute to cost savings in marine applications?

They reduce long-term costs by minimizing maintenance requirements, extending service life, and often eliminating the need for additional protective measures.

Can nickel alloy plates withstand deep-sea conditions?

Yes, nickel alloy plates can withstand high pressures and corrosive environments encountered in deep-sea applications, making them suitable for use in research vessels and underwater installations.

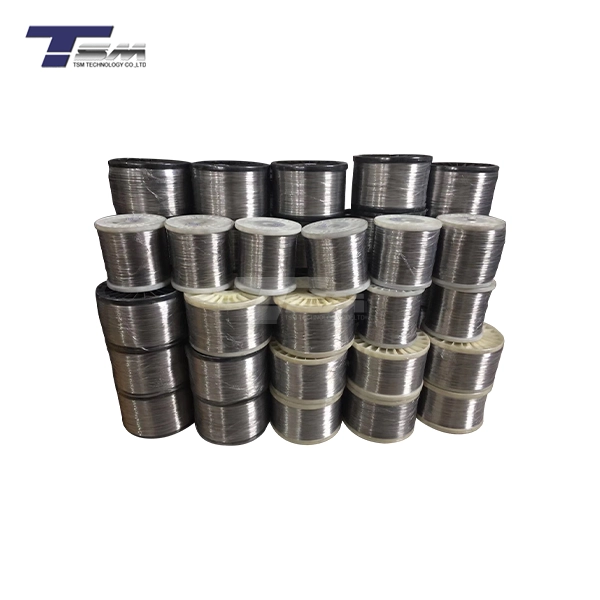

Superior Nickel Alloy Plate Solutions for Marine Applications | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality nickel alloy plates tailored for demanding marine environments. Our advanced manufacturing processes and strict quality control ensure superior corrosion resistance and reliability. As a leading nickel alloy plate manufacturer and supplier, we offer innovative solutions to meet the evolving needs of the marine industry. Contact our expert team at info@tsmnialloy.com to discover how our premium nickel alloy plates can enhance your marine projects.

References

Smith, J.R. (2020). "Corrosion Behavior of Nickel Alloys in Marine Environments." Journal of Marine Engineering and Materials Science, 15(3), 245-260.

Johnson, A.B. & Lee, C.M. (2019). "Advanced Materials for Offshore Applications: A Focus on Nickel Alloys." Offshore Technology Conference Proceedings, Houston, TX.

Wang, L., et al. (2021). "Electrochemical Performance of High-Nickel Alloys in Simulated Seawater Conditions." Corrosion Science, 168, 108595.

Marine Corrosion Institute. (2018). "Handbook of Corrosion-Resistant Alloys for Maritime Applications." 3rd Edition, London: Nautical Press.

Gonzalez, M.R. & Patel, S.K. (2022). "Long-term Performance Analysis of Nickel Alloy Components in Offshore Structures." International Journal of Offshore and Polar Engineering, 32(1), 78-92.

Thompson, E.L. (2020). "Innovations in Marine Materials: From Shipbuilding to Renewable Energy." Annual Review of Materials Research, 50, 331-355.