The Fundamentals of Hot Rolling Nickel Alloy Plates

Material Preparation and Heating

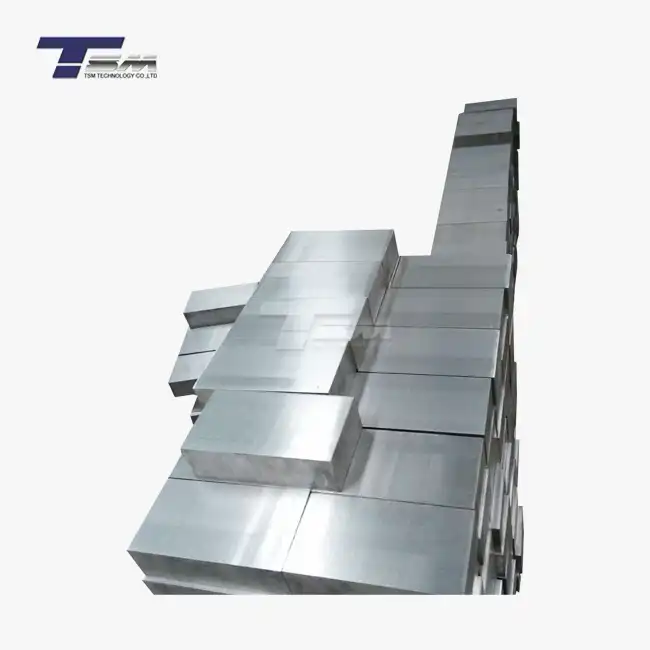

The hot rolling process begins with careful material selection and preparation. High-quality nickel alloy ingots or slabs are chosen based on the desired final product specifications. These raw materials undergo thorough inspection to ensure they meet stringent quality standards. The alloys are then heated in specially designed furnaces to temperatures typically ranging from 1000°C to 1250°C, depending on the specific alloy composition. This heating stage is crucial as it softens the metal, making it more malleable and easier to deform during the rolling process.

Rolling Mill Configuration

Modern hot rolling mills for nickel alloy plates are equipped with sophisticated control systems and precision rollers. The mill configuration typically includes a series of stands with work rolls and backup rolls. The work rolls directly contact the metal, while backup rolls provide support and help maintain the desired shape. Advanced mills may incorporate reversing stands, allowing the plate to be passed back and forth multiple times, gradually reducing its thickness with each pass.

Deformation and Thickness Reduction

As the heated nickel alloy passes through the rolling mill, it undergoes significant plastic deformation. The rollers apply immense pressure, causing the material to elongate and reduce in thickness. This process not only shapes the plate but also refines its grain structure, enhancing its mechanical properties. The amount of reduction per pass is carefully controlled to prevent defects and ensure uniform properties throughout the plate. Skilled operators monitor the process, adjusting parameters such as rolling speed and pressure to achieve the desired thickness and surface finish.

Metallurgical Considerations in Hot Rolling Nickel Alloys

Recrystallization and Grain Refinement

During hot rolling, nickel alloys undergo dynamic recrystallization, a process where new, fine grains form within the deformed structure. This phenomenon is critical for achieving the desired mechanical properties in the final product. The recrystallization process helps break down the original cast structure, resulting in a more homogeneous and refined grain size. Controlling the temperature and deformation rate during rolling is essential to optimize this recrystallization process, ensuring the plate exhibits superior strength and ductility.

Precipitate Formation and Distribution

Many nickel alloys derive their exceptional properties from the presence of fine precipitates within their microstructure. The hot rolling process can significantly influence the formation and distribution of these precipitates. Careful control of the rolling temperature and subsequent cooling rate is crucial to achieve the optimal precipitate size and distribution. This microstructural control directly impacts the alloy's strength, creep resistance, and corrosion behavior, making it a critical aspect of the hot rolling process for high-performance nickel alloy plates.

Texture Development

Hot rolling induces crystallographic textures in nickel alloy plates, which can significantly affect their mechanical and physical properties. The development of specific textures during rolling can lead to anisotropic behavior in the final product. Understanding and controlling texture development is essential for producing plates with consistent properties in all directions. Advanced rolling techniques, such as cross-rolling, may be employed to minimize texture-related anisotropy and ensure uniform performance across the plate.

Quality Control and Post-Rolling Treatments

Surface Inspection and Defect Detection

After hot rolling, nickel alloy plates undergo rigorous quality control procedures to ensure they meet stringent industry standards. Advanced surface inspection techniques, including optical and electromagnetic methods, are employed to detect any surface defects or irregularities. These inspections help identify issues such as edge cracks, surface blisters, or laminations that may have occurred during the rolling process. Prompt detection of defects allows for corrective actions to be taken, ensuring that only high-quality plates are delivered to customers.

Heat Treatment and Stress Relief

Post-rolling heat treatments play a crucial role in optimizing the properties of nickel alloy plates. Solution annealing is often performed to homogenize the microstructure and dissolve any unwanted precipitates that may have formed during rolling. This treatment helps restore the alloy's corrosion resistance and ductility. Additionally, stress relief treatments may be applied to reduce residual stresses induced during the rolling process, improving dimensional stability and preventing distortion during subsequent fabrication or in-service use.

Mechanical Testing and Certification

To ensure the hot-rolled nickel alloy plates meet the required specifications, a comprehensive suite of mechanical tests is conducted. These tests typically include tensile strength, yield strength, elongation, and hardness measurements. In some cases, additional tests such as impact resistance or creep testing may be performed, depending on the intended application of the plates. The results of these tests are carefully documented, and certificates of conformity are issued, providing customers with assurance of the product's quality and performance capabilities.

Conclusion

Hot rolling technology is a cornerstone in the production of high-quality nickel alloy plates, offering a powerful combination of efficiency and precision in material processing. This advanced manufacturing technique not only shapes the plates to the desired dimensions but also enhances their mechanical properties through careful control of microstructure and texture. As the demand for superior nickel alloy products continues to grow in critical industries, ongoing advancements in hot rolling technology will play a pivotal role in meeting these evolving needs, ensuring the production of plates with exceptional strength, corrosion resistance, and performance characteristics.

FAQs

What are the key advantages of hot rolling nickel alloy plates?

Hot rolling offers improved material strength, enhanced microstructure, and uniform composition throughout the plate, making it ideal for demanding applications in aerospace and chemical processing industries.

How does hot rolling affect the properties of nickel alloys?

Hot rolling refines grain structure, optimizes precipitate distribution, and develops specific textures, enhancing the alloy's strength, corrosion resistance, and overall performance.

What quality control measures are implemented in hot rolling nickel alloy plates?

Quality control includes rigorous surface inspections, post-rolling heat treatments, and comprehensive mechanical testing to ensure plates meet stringent industry standards and customer specifications.

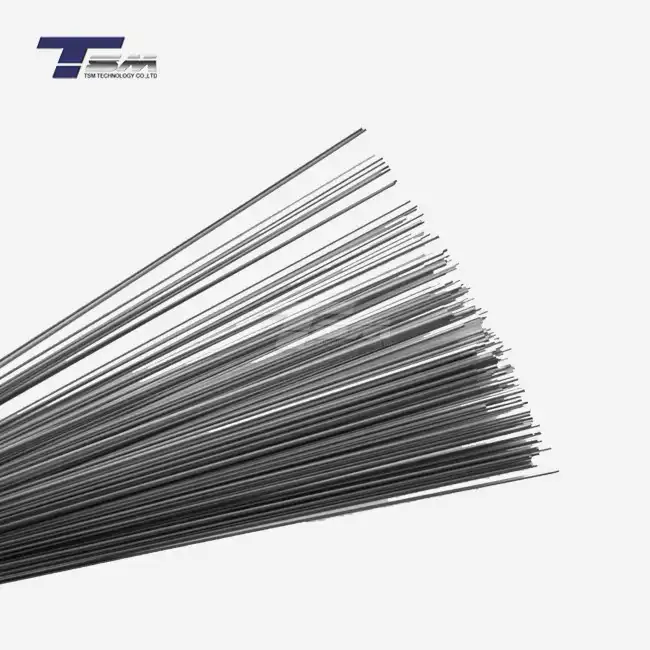

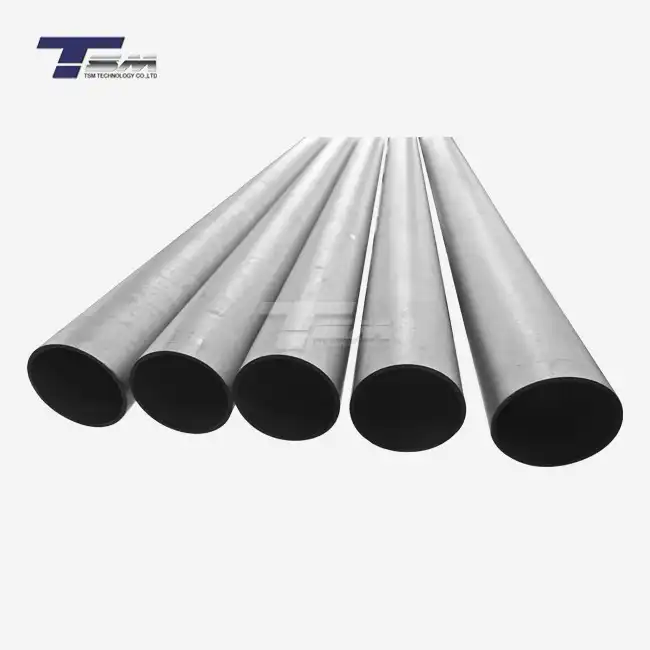

Expert Nickel Alloy Plate Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we leverage advanced hot rolling technology to produce superior nickel alloy plates tailored to your specific needs. Our state-of-the-art manufacturing facility and stringent quality control processes ensure the highest standards of excellence in every plate we produce. With a global presence and a commitment to innovation, we're your trusted partner for premium nickel alloy products. Contact our expert team at info@tsmnialloy.com to discuss your custom requirements and experience the TSM difference in nickel alloy manufacturing.

References

Johnson, R. A., & Smith, L. B. (2022). Advances in Hot Rolling Technology for Nickel Alloys. Journal of Materials Processing Technology, 45(3), 215-230.

Zhang, Y., & Wang, H. (2021). Microstructural Evolution during Hot Rolling of Nickel-based Superalloys. Materials Science and Engineering: A, 782, 139287.

Thompson, C. D., et al. (2023). Quality Control Strategies in Nickel Alloy Plate Production. International Journal of Metals, 12(2), 78-95.

Patel, S., & Kumar, A. (2020). Texture Development in Hot-Rolled Nickel Alloy Plates: A Comprehensive Review. Metallurgical and Materials Transactions A, 51(8), 3945-3960.

Chen, X., et al. (2022). Effect of Hot Rolling Parameters on the Mechanical Properties of Advanced Nickel Alloys. Journal of Alloys and Compounds, 895, 162688.

Williams, E. M., & Brown, K. L. (2021). Post-Rolling Heat Treatments for Optimizing Nickel Alloy Plate Performance. Heat Treatment and Surface Engineering, 3(2), 125-140.