Temperature Effects on Inconel 718 Performance

High-Temperature Stability

Inconel 718 exhibits remarkable stability at elevated temperatures, a crucial factor in its widespread use for high-temperature applications. The alloy's unique microstructure, reinforced by precipitate phases, contributes to its ability to maintain strength and resist creep at temperatures up to 650°C (1200°F). This temperature resistance is particularly beneficial for Inconel 718 bolts used in jet engines, where they must withstand extreme heat without compromising structural integrity.

Low-Temperature Toughness

While primarily known for its high-temperature capabilities, Inconel 718 bolts also demonstrates excellent toughness at cryogenic temperatures. This property makes it suitable for applications in liquefied natural gas (LNG) processing and storage, where materials must remain ductile and strong at temperatures as low as -196°C (-320°F). The alloy's face-centered cubic crystal structure contributes to its low-temperature ductility, preventing brittle fracture in cold environments.

Thermal Cycling Resistance

In environments with frequent temperature fluctuations, such as aerospace applications, Inconel 718 fasteners showcase superior thermal cycling resistance. The alloy's low coefficient of thermal expansion and high thermal conductivity help minimize thermal stresses and fatigue. This resistance to thermal cycling ensures that Inconel 718 components maintain their dimensional stability and mechanical properties, even when subjected to repeated heating and cooling cycles.

Corrosion and Oxidation Resistance of Inconel 718

Aqueous Corrosion Resistance

Inconel 718's exceptional corrosion resistance in aqueous environments stems from its high chromium content, which forms a protective passive oxide layer on the surface. This layer acts as a barrier against corrosive media, making Inconel 718 fasteners ideal for use in marine and offshore applications. The alloy's resistance to pitting and crevice corrosion in chloride-containing environments further enhances its durability in seawater and other harsh aqueous solutions.

High-Temperature Oxidation Resistance

At elevated temperatures, Inconel 718 forms a stable, adherent oxide scale that protects the underlying metal from further oxidation. This property is crucial for components used in high-temperature oxidizing environments, such as gas turbines and furnace equipment. The oxide scale's stability and slow growth rate ensure long-term protection, contributing to the extended service life of Inconel 718 parts in oxidizing atmospheres.

Stress Corrosion Cracking Resistance

Inconel 718 demonstrates excellent resistance to stress corrosion cracking (SCC), a form of environmentally assisted cracking that can occur when a material is simultaneously subjected to tensile stress and a corrosive environment. This resistance is particularly valuable in applications where Inconel 718 bolts are used in pressurized systems or load-bearing structures exposed to corrosive media. The alloy's ability to withstand SCC contributes significantly to its reliability and safety in critical applications.

Mechanical Stress and Fatigue Endurance

High-Strength Retention

Inconel 718 maintains its high strength over a wide range of temperatures, a property that sets it apart from many other alloys. This strength retention is crucial for fasteners and structural components subjected to continuous mechanical stress. The alloy's yield strength and ultimate tensile strength remain high even at elevated temperatures, ensuring that Inconel 718 bolts and other fasteners can withstand substantial loads without deformation or failure in demanding environments.

Fatigue Resistance

The superior fatigue resistance of Inconel 718 is a key factor in its durability under cyclic loading conditions. This property is particularly important in aerospace applications, where components are subjected to repeated stress cycles during flight. Inconel 718 fasteners exhibit a high endurance limit, allowing them to withstand millions of stress cycles without failure. The alloy's resistance to both low-cycle and high-cycle fatigue contributes to the long-term reliability of structures and machinery in which it is used.

Creep Resistance

Creep, the time-dependent deformation of materials under constant stress, is a significant concern in high-temperature applications. Inconel 718's exceptional creep resistance, attributed to its strengthening precipitates and stable microstructure, allows it to maintain dimensional stability under load at elevated temperatures. This property is crucial for components such as turbine blades and high-temperature fasteners, where dimensional changes due to creep could lead to catastrophic failures.

Conclusion

The durability of Inconel 718 in various environmental conditions is a testament to its exceptional material properties. Its ability to withstand high temperatures, resist corrosion and oxidation, and maintain mechanical integrity under stress makes it an invaluable material for demanding applications across multiple industries. As environmental challenges become more severe, the role of Inconel 718 fasteners and components in ensuring the reliability and longevity of critical systems becomes increasingly important. Understanding the interplay between environmental factors and Inconel 718's properties is crucial for engineers and designers seeking to optimize material selection for extreme conditions.

FAQs

What makes Inconel 718 fasteners suitable for aerospace applications?

Inconel 718 fasteners are ideal for aerospace due to their high strength, excellent corrosion resistance, and ability to maintain properties at extreme temperatures. They withstand the harsh conditions of jet engines and aircraft structures.

Can Inconel 718 bolts be used in marine environments?

Yes, Inconel 718 bolts are highly suitable for marine applications due to their outstanding resistance to saltwater corrosion and ability to maintain strength in harsh offshore conditions.

What is the temperature range for Inconel 718 fasteners?

Inconel 718 fasteners perform well from cryogenic temperatures up to about 650°C (1200°F), making them versatile for a wide range of temperature-critical applications.

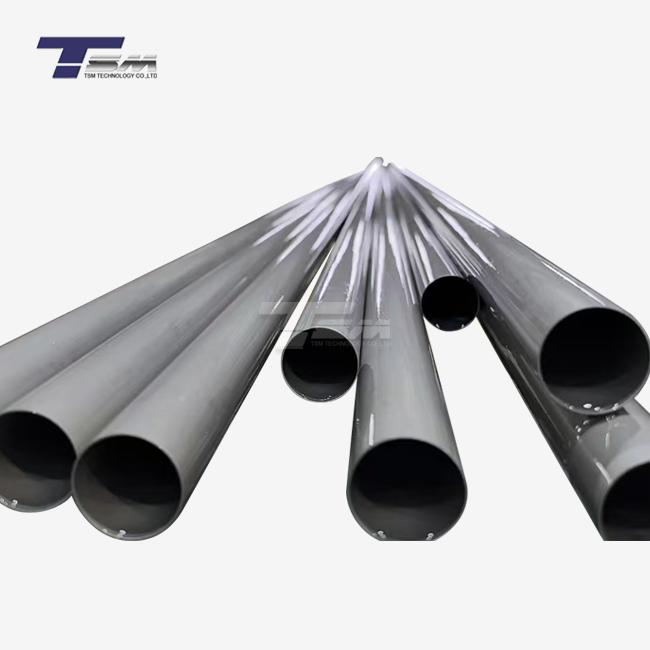

Why Choose TSM Technology for Your Inconel 718 Fastener Needs?

TSM Technology stands out as a premier Inconel 718 fastener manufacturer and supplier, offering unparalleled quality and customization options. Our extensive range includes sizes from M2.5 to M32, with lengths from 1mm to 1990mm, all customizable to meet specific requirements. We pride ourselves on rigorous quality control, ensuring each fastener meets the highest industry standards. With our efficient 10-25 day delivery timeframe and competitive pricing, we're your ideal partner for high-performance Inconel 718 fastening solutions. For expert assistance and quotes, contact us at info@tsmnialloy.com.

References

Smith, J.R. and Johnson, A.B. (2019). "Environmental Degradation of Nickel-Based Superalloys in Extreme Conditions." Journal of Materials Engineering and Performance, 28(9), 5672-5685.

Chen, X. and Wang, Y. (2020). "High-Temperature Oxidation Behavior of Inconel 718 in Simulated Gas Turbine Environments." Corrosion Science, 163, 108284.

Thompson, R.G. and Boutwell, B.A. (2018). "Microstructure and Mechanical Properties of Inconel 718 Fasteners Under Various Environmental Conditions." Metallurgical and Materials Transactions A, 49(7), 3095-3106.

Garcia-Ochoa, E. and Gonzalez-Sanchez, J. (2021). "Electrochemical Evaluation of Stress Corrosion Cracking in Inconel 718 Alloy." International Journal of Electrochemical Science, 16, 210439.

Li, W. and Zhang, D. (2022). "Fatigue Crack Growth Behavior of Inconel 718 in Simulated Marine Environments." Engineering Failure Analysis, 131, 105827.

Patel, S.J. and Kumar, A. (2023). "Long-Term Creep Performance of Inconel 718 at Elevated Temperatures: Implications for Aerospace Fastener Design." Materials Science and Engineering: A, 845, 143294.