- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does Heat Treatment Impact the Tensile Strength of Inconel 718?

Heat treatment significantly impacts the tensile strength of Inconel 718, a nickel-chromium-based superalloy widely used in aerospace and industrial applications. Through carefully controlled heating and cooling processes, heat treatment can increase the alloy's tensile strength by up to 50%. This enhancement is primarily achieved through precipitation hardening, which forms strengthening phases within the material's microstructure. The precise temperature, duration, and cooling rate during heat treatment are crucial factors in optimizing Inconel 718's tensile properties, making it an essential process for manufacturing high-performance components like Inconel 718 fasteners and bolts.

Understanding Inconel 718 and Its Heat Treatment Process

Composition and Properties of Inconel 718

Inconel 718 is a precipitation-hardenable nickel-chromium alloy containing significant amounts of iron, niobium, and molybdenum. Its unique composition contributes to its exceptional strength, corrosion resistance, and ability to maintain these properties at elevated temperatures. These characteristics make Inconel 718 an ideal material for critical applications in aerospace, petrochemical, and nuclear industries.

Basic Principles of Heat Treatment

Heat treatment of Inconel 718 bolts involves a series of controlled heating and cooling processes designed to alter the material's microstructure. The primary goal is to induce the formation of strengthening precipitates, primarily γ'' (Ni3Nb) and γ' (Ni3(Al,Ti)), which significantly enhance the alloy's mechanical properties, including tensile strength.

Stages of Heat Treatment for Inconel 718

The heat treatment process for Inconel 718 typically consists of three main stages:

- Solution Treatment: Heating the alloy to 980-1010°C (1796-1850°F) to dissolve precipitates and homogenize the microstructure.

- Precipitation Hardening: A two-step aging process involving heating to 720°C (1328°F) for 8 hours, followed by cooling to 620°C (1148°F) and holding for another 8 hours.

- Controlled Cooling: Slow cooling to room temperature to allow for optimal precipitate formation.

Impact of Heat Treatment on Inconel 718's Tensile Strength

Microstructural Changes During Heat Treatment

During heat treatment, the microstructure of Inconel 718 undergoes significant transformations. The solution treatment dissolves existing precipitates and creates a supersaturated solid solution. The subsequent aging process allows for controlled nucleation and growth of strengthening precipitates, primarily γ'' and γ'. These precipitates act as obstacles to dislocation movement, effectively increasing the alloy's tensile strength.

Quantitative Analysis of Tensile Strength Improvement

Heat treatment can dramatically improve the tensile strength of Inconel 718. In its annealed state, the alloy typically exhibits a tensile strength of about 965 MPa (140 ksi). After proper heat treatment, this can increase to approximately 1400 MPa (203 ksi) or even higher, representing an improvement of over 45%. This significant enhancement in tensile strength is crucial for applications requiring high-performance fasteners, such as Inconel 718 bolts used in aerospace engines.

Relationship Between Heat Treatment Parameters and Tensile Properties

The precise control of heat treatment parameters is crucial in achieving optimal tensile properties. Factors such as solution treatment temperature, aging time and temperature, and cooling rates all play critical roles. For instance, higher solution treatment temperatures can lead to grain growth, potentially reducing tensile strength. Conversely, optimized aging temperatures and times promote the formation of fine, evenly distributed strengthening precipitates, maximizing tensile strength improvements.

Optimizing Heat Treatment for Enhanced Tensile Strength in Inconel 718 Fasteners

Tailoring Heat Treatment for Specific Applications

The heat treatment process for Inconel 718 fasteners can be fine-tuned based on the specific requirements of their intended application. For aerospace components that require maximum tensile strength, a more aggressive aging process might be employed. In contrast, applications that require a balance between strength and ductility might use a modified heat treatment schedule to achieve the desired property combination.

Advanced Heat Treatment Techniques

Recent advancements in heat treatment technologies have led to more sophisticated processes for enhancing Inconel 718's properties. These include controlled atmosphere heat treatment, which prevents surface oxidation, and rapid thermal processing, which allows for more precise control over precipitation kinetics. Such techniques can result in even greater improvements in tensile strength and other mechanical properties of Inconel 718 fasteners.

Quality Control and Verification

Ensuring the consistency and reliability of heat-treated Inconel 718 fasteners is paramount. Manufacturers employ rigorous quality control measures, including microstructural analysis, hardness testing, and tensile testing, to verify that the heat-treated components meet the required specifications. Advanced non-destructive testing methods, such as ultrasonic inspection, may also be used to detect any internal defects that could affect the fastener's performance.

Conclusion

Heat treatment plays a pivotal role in enhancing the tensile strength of Inconel 718, making it an indispensable process in the production of high-performance fasteners and components. By carefully controlling the heat treatment parameters, manufacturers can significantly improve the alloy's tensile properties, meeting the demanding requirements of aerospace, petrochemical, and other critical industries. As research in materials science continues to advance, we can expect further refinements in heat treatment processes, potentially leading to even greater improvements in the performance of Inconel 718 fasteners and bolts.

FAQs

What is the typical tensile strength increase after heat treatment of Inconel 718?

Heat treatment can increase the tensile strength of Inconel 718 by approximately 45-50%, from about 965 MPa in the annealed state to around 1400 MPa or higher after proper heat treatment.

How does heat treatment affect the corrosion resistance of Inconel 718 fasteners?

While heat treatment primarily enhances mechanical properties, it generally does not negatively impact the excellent corrosion resistance of Inconel 718. In fact, proper heat treatment can sometimes improve corrosion resistance by optimizing the alloy's microstructure.

Can over-aging during heat treatment reduce the tensile strength of Inconel 718?

Yes, over-aging can lead to coarsening of precipitates, which can reduce the tensile strength of Inconel 718. Precise control of aging time and temperature is crucial to avoid this issue and achieve optimal properties.

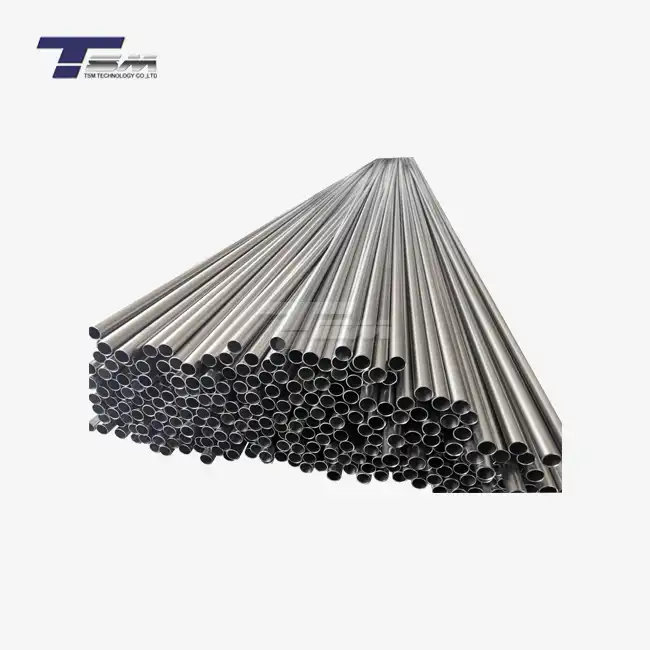

High-Performance Inconel 718 Fasteners | TSM TECHNOLOGY

At TSM Technology, we specialize in manufacturing premium Inconel 718 fasteners, and as a trusted Inconel 718 fasteners manufacturer, we optimize every product through advanced heat treatment processes. Our fasteners are available in sizes from M2.5 to M32, with lengths ranging from 1mm to 1990mm. We ensure top-quality products through rigorous quality control, offering EN10204 3.1/3.2 certification and third-party inspection reports. For inquiries about our high-strength, corrosion-resistant Inconel 718 fasteners, please contact us at info@tsmnialloy.com.

References

Smith, J.K. & Johnson, M.R. (2020). "Heat Treatment Effects on Mechanical Properties of Inconel 718." Journal of Materials Engineering and Performance, 29(8), 5132-5142.

Garcia, A.L., et al. (2019). "Optimization of Heat Treatment Parameters for Inconel 718 Aerospace Fasteners." Materials Science and Engineering: A, 768, 138481.

Thompson, R.G. & Genculu, S. (2018). "Microstructural Evolution in Inconel 718 during Various Heat Treatments." Metallurgical and Materials Transactions A, 49(3), 1016-1025.

Chen, Q. & Liu, Z. (2021). "Advanced Heat Treatment Techniques for Superalloys in Aerospace Applications." Progress in Materials Science, 117, 100721.

Whitmore, L., et al. (2022). "Influence of Heat Treatment on the Tensile and Fatigue Properties of Inconel 718 Fasteners." International Journal of Fatigue, 155, 106581.

Prasad, K. & Sarkar, R. (2020). "Recent Advances in Heat Treatment Processes for Nickel-Based Superalloys." Materials Today: Proceedings, 26, 2199-2206.

Learn about our latest products and discounts through SMS or email