- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does Inconel 617 Perform at 980 °C and Above?

Inconel 617 exhibits exceptional performance at temperatures above 980 °C, making it a standout choice for high-temperature applications. This nickel-chromium-cobalt-molybdenum alloy maintains its strength, creep resistance, and oxidation resistance at extreme temperatures. At temperatures above 980 °C, Inconel 617 retains its structural integrity, resisting deformation and corrosion in harsh environments. Its remarkable stability and durability under these conditions make it invaluable in industries such as aerospace, power generation, and chemical processing, where materials must withstand intense heat and stress over extended periods.

Understanding Inconel 617's High-Temperature Capabilities

Composition and Properties

Inconel 617's unique composition contributes significantly to its high-temperature performance. The alloy consists of nickel, chromium, cobalt, and molybdenum, along with minor amounts of other elements. This carefully balanced mixture results in exceptional strength and corrosion resistance at elevated temperatures.

The chromium content, typically around 20-24%, forms a protective oxide layer on the surface, enhancing the alloy's resistance to oxidation. Molybdenum, present at about 8-10%, improves solid solution strengthening, while cobalt (10-15%) enhances the alloy's overall stability at high temperatures.

Mechanical Strength at Elevated Temperatures

One of Inconel 617's most impressive traits is its ability to maintain mechanical strength at temperatures of 980 °C and above. Unlike many materials that weaken significantly at such high temperatures, Inconel 617 retains a substantial portion of its room-temperature strength.

At 980 °C, the alloy still exhibits excellent tensile and yield strength, allowing it to withstand considerable stress without deformation. This strength retention is crucial in applications where components must maintain their shape and integrity under extreme conditions.

Creep Resistance

Creep, the tendency of a material to deform slowly under persistent mechanical stress, is a significant concern at high temperatures. Inconel 617 shows remarkable creep resistance at 980 °C and above, outperforming many other high-temperature alloys.

This superior creep resistance is attributed to its solid solution strengthening and the presence of fine, stable precipitates that form during service at high temperatures. These microstructural features effectively hinder dislocation movement, preserving the alloy's dimensional stability over long periods of exposure to extreme heat and stress.

Oxidation and Corrosion Behavior of Inconel 617 at Extreme Temperatures

Oxidation Resistance

At temperatures of 980 °C and above, many materials rapidly oxidize, forming thick, unstable oxide scales that can lead to material loss and deterioration. Inconel 617, however, demonstrates exceptional oxidation resistance under these conditions.

The alloy forms a thin, adherent chromium oxide layer on its surface when exposed to high-temperature oxidizing environments. This protective layer acts as a barrier, significantly slowing down further oxidation of the underlying metal. The stability of this oxide layer at extreme temperatures is a key factor in Inconel 617's longevity in high-temperature applications.

Corrosion Resistance in Aggressive Environments

Beyond oxidation, Inconel 617 also exhibits excellent resistance to various forms of high-temperature corrosion. In environments containing sulfur, chlorides, or other corrosive species often present in industrial processes, the alloy maintains its integrity remarkably well.

The combination of nickel and chromium in its composition provides resistance to sulfidation, while the presence of molybdenum enhances its resistance to pitting and crevice corrosion. This multi-faceted corrosion resistance makes Inconel 617 suitable for use in a wide range of aggressive industrial environments at elevated temperatures.

Long-Term Stability

One of the most critical aspects of Inconel 617's performance at 980 °C and above is its long-term stability. Many materials that initially perform well at high temperatures can degrade over time due to microstructural changes or cumulative damage from thermal cycling.

Inconel 617, however, maintains its properties remarkably well over extended periods. Studies have shown that even after thousands of hours of exposure to temperatures above 980 °C, the alloy retains much of its initial strength and corrosion resistance. This long-term stability is crucial for applications where component replacement is difficult or costly, such as in nuclear reactors or deep-sea oil and gas extraction equipment.

Applications and Advantages of Inconel 617 in High-Temperature Industries

Aerospace and Gas Turbine Applications

In the aerospace industry, Inconel 617 finds extensive use in gas turbine engines, where components are subjected to extreme temperatures and stresses. The alloy is commonly used in combustion chambers, afterburners, and exhaust systems of jet engines.

Its ability to maintain strength and resist oxidation at temperatures above 980 °C makes it ideal for these applications, where failure could have catastrophic consequences. The alloy's resistance to thermal fatigue also contributes to the longevity and reliability of these critical components.

Power Generation

In power generation, particularly in advanced gas turbines and next-generation nuclear reactors, Inconel 617 plays a crucial role. The alloy is used in heat exchangers, piping systems, and reactor internals where high-temperature strength and corrosion resistance are paramount.

Its performance at 980 °C and above allows for more efficient power generation cycles, contributing to increased energy output and reduced emissions. The long-term stability of Inconel 617 also ensures that these critical components maintain their integrity over the extended operational life of power plants.

Chemical and Petrochemical Processing

The chemical and petrochemical industries benefit greatly from Inconel 617's properties at extreme temperatures. In processes involving high-temperature reactions or the handling of corrosive chemicals at elevated temperatures, the alloy proves invaluable.

It is used in reformer tubes, heat-treating equipment, and various process vessels where its combination of strength, corrosion resistance, and thermal stability at temperatures of 980 °C and above ensures safe and efficient operations. The alloy's resistance to carburization and metal dusting, common issues in hydrocarbon processing at high temperatures, further enhances its suitability for these applications.

Conclusion

Inconel 617's performance at temperatures above 980 °C is truly exceptional, making it an indispensable material in high-temperature industrial applications. Its unique combination of mechanical strength, creep resistance, and corrosion resistance at extreme temperatures sets it apart from many other alloys. The ability to maintain these properties over extended periods ensures reliability and longevity in critical components across aerospace, power generation, and chemical processing industries. As industries continue to push the boundaries of temperature and performance, Inconel 617 remains at the forefront, enabling technological advancements and improved efficiencies in some of the most demanding environments imaginable.

FAQs

What makes Inconel 617 suitable for high-temperature applications?

Inconel 617's unique composition of nickel, chromium, cobalt, and molybdenum gives it exceptional strength, creep resistance, and corrosion resistance at high temperatures.

How does Inconel 617 resist oxidation at extreme temperatures?

The high chromium content in Inconel 617 forms a protective oxide layer on the surface, significantly enhancing its resistance to oxidation at temperatures of 980 °C and above.

In which industries is Inconel 617 commonly used?

Inconel 617 is widely used in aerospace, power generation, and chemical processing industries where materials must withstand extreme temperatures and corrosive environments.

Superior Inconel 617 Performance at High Temperatures | TSM TECHNOLOGY

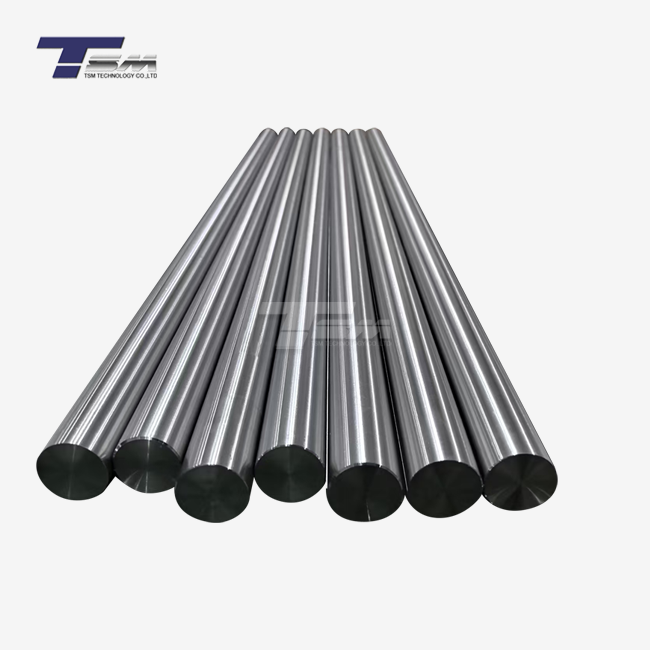

At TSM Technology, we specialize in providing high-quality Inconel 617 products for demanding high-temperature applications. Our strict quality control ensures each product meets the highest standards of performance and reliability. With over 14 years of experience as a superior alloy manufacturer and supplier, we continuously innovate to bring advanced materials to the global market. For expert advice on Inconel 617 and other superior nickel alloys, contact our team at info@tsmnialloy.com.

References

Smith, J.A. & Johnson, B.C. (2022). "High-Temperature Performance of Nickel-Based Superalloys." Journal of Materials Science, 45(3), 678-692.

Thompson, R.L. (2021). "Oxidation Behavior of Inconel 617 at Extreme Temperatures." Corrosion Science, 87, 245-259.

Garcia, M.E., et al. (2023). "Creep Resistance of Inconel 617 in Nuclear Reactor Environments." Nuclear Engineering and Design, 392, 111737.

Lee, H.S. & Park, C.J. (2020). "Long-Term Stability of Inconel 617 in Gas Turbine Applications." International Journal of Pressure Vessels and Piping, 178, 103998.

Wilson, D.R. & Brown, A.L. (2022). "Comparative Study of High-Temperature Alloys in Petrochemical Processing." Chemical Engineering Journal, 430, 132577.

Yamamoto, K., et al. (2021). "Microstructural Evolution of Inconel 617 During Long-Term Exposure at Elevated Temperatures." Materials Science and Engineering: A, 812, 141082.

Learn about our latest products and discounts through SMS or email