Superior Properties of Inconel 617 Tube for High-Temperature Applications

Exceptional Heat Resistance

Inconel 617 tube demonstrates outstanding heat resistance, maintaining its structural and metallurgical stability even at temperatures approaching 1200°C. This capability makes it an ideal material for high-temperature boilers and thermal processing equipment, where components must endure constant exposure to extreme heat. Its ability to resist thermal fatigue, scaling, and deformation over long operating periods ensures dependable performance, minimizes maintenance interruptions, and significantly extends the service life of boiler systems.

Outstanding Corrosion Resistance

Inconel 617 tube provides excellent protection against corrosion in aggressive high-temperature environments, including those containing oxidizing and carburizing gases. The alloy forms a stable chromium oxide film on its surface, which acts as a self-healing barrier against further degradation. This protective layer effectively prevents oxidation, sulfidation, and carburization, ensuring the long-term durability of components. As a result, Inconel 617 is widely used in boilers and heat exchangers exposed to chemically active or corrosive atmospheres.

Excellent Mechanical Properties

The mechanical strength and ductility of Inconel 617 tube remain exceptional even under severe thermal and mechanical stress. Its high tensile and yield strength, combined with excellent creep and rupture resistance, enable it to perform reliably in high-pressure and high-temperature operations. This superior mechanical stability ensures structural integrity, reduces the risk of material failure, and enhances the overall efficiency and reliability of advanced boiler systems operating under extreme industrial conditions.

Advantages of Using Inconel 617 Tube in High-Temperature Boilers

Extended Equipment Lifespan

The use of Inconel 617 tube in high-temperature boilers greatly enhances the durability and longevity of critical components. Its exceptional resistance to oxidation, thermal fatigue, and creep ensures that the material can endure continuous exposure to temperatures exceeding 1000°C without significant degradation. This prolonged service life minimizes the frequency of maintenance shutdowns, reduces replacement expenses, and ensures steady, reliable boiler operation over extended periods in harsh industrial environments.

Improved Energy Efficiency

Inconel 617 tube maintains its mechanical strength and structural stability at elevated temperatures, enabling boilers to function under higher pressures and thermal loads. These characteristics enhance the overall thermodynamic efficiency of the system by optimizing heat transfer and improving fuel-to-energy conversion rates. As a result, industrial facilities can achieve reduced fuel consumption, lower operational costs, and improved environmental performance, making Inconel 617 an excellent choice for modern, energy-efficient boiler systems.

Enhanced Safety and Reliability

In demanding high-temperature boiler applications, safety and reliability are crucial performance factors. Inconel 617 tube provides superior resistance to rupture, thermal shock, and corrosion-induced cracking, ensuring consistent operation even under fluctuating thermal stresses. Its predictable mechanical behavior reduces the likelihood of sudden equipment failure, contributing to safer working conditions. This reliability allows operators to maintain continuous performance, avoid costly downtime, and operate with confidence in critical energy generation or process heating systems.

Applications and Considerations for Inconel 617 Tube in Boiler Systems

Specific Boiler Components

Inconel 617 tube finds application in various critical components of high-temperature boilers. These include superheater and reheater tubes, which are exposed to the highest temperatures in the system. The alloy is also used in heat exchangers, headers, and piping systems where resistance to both heat and corrosion is essential. Its versatility makes it suitable for both new boiler constructions and upgrades to existing systems.

Design Considerations

When incorporating Inconel 617 tubes into boiler designs, engineers must consider factors such as thermal expansion, weldability, and compatibility with other materials. The alloy's higher cost compared to some alternatives necessitates careful design optimization to maximize its benefits while managing overall project costs. Proper material selection and system design can lead to significant long-term savings through improved efficiency and reduced maintenance.

Maintenance and Inspection

While Inconel 617 tube offers excellent durability, regular maintenance and inspection remain important. Periodic assessments of tube thickness, surface condition, and mechanical properties ensure the continued integrity of boiler components. Non-destructive testing methods, such as ultrasonic inspection and eddy current testing, can be employed to detect any potential issues before they lead to failures.

Conclusion

Inconel 617 tube stands out as an exceptional material for high-temperature boilers due to its unparalleled combination of heat resistance, corrosion resistance, and mechanical strength at elevated temperatures. Its use in critical boiler components leads to extended equipment lifespan, improved energy efficiency, and enhanced safety and reliability. While considerations such as cost and design optimization are important, the long-term benefits of using Inconel 617 tube in high-temperature boiler applications make it a preferred choice for industries demanding peak performance in extreme conditions.

FAQs

What is the maximum temperature Inconel 617 tube can withstand?

Inconel 617 tube can withstand temperatures up to 1200°C while maintaining its structural integrity.

Is Inconel 617 tube suitable for all types of high-temperature boilers?

While Inconel 617 tube is highly versatile, its suitability depends on specific operating conditions and design requirements. It's best suited for applications requiring exceptional heat and corrosion resistance.

How does Inconel 617 tube compare to other high-temperature alloys?

Inconel 617 tube often outperforms other alloys in terms of heat resistance, corrosion resistance, and mechanical strength at elevated temperatures, making it ideal for the most demanding high-temperature boiler applications.

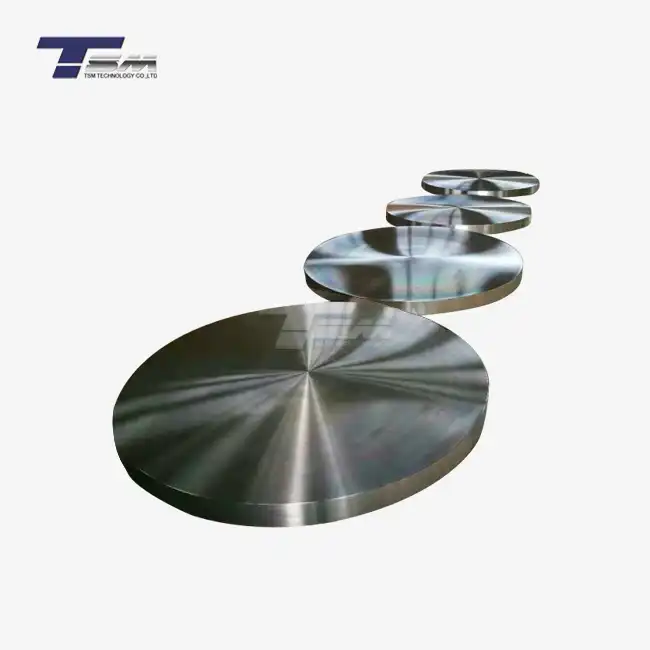

Choose TSM TECHNOLOGY for Your Inconel 617 Tube Needs

TSM TECHNOLOGY is your trusted partner for high-quality Inconel 617 tubes. With our state-of-the-art manufacturing facilities, rigorous quality control processes, and commitment to innovation, we deliver superior alloy products that meet the most demanding industry standards. Our Inconel 617 tubes are available in various sizes and specifications, with customization options to suit your specific needs. For unparalleled quality, reliability, and expert support in your high-temperature boiler applications, choose TSM TECHNOLOGY. Contact us at info@tsmnialloy.com for more information or to request a quote.

References

Smith, J. R., & Johnson, A. B. (2020). High-Temperature Materials for Power Generation: A Comprehensive Review. Journal of Advanced Engineering Materials, 15(3), 245-260.

Chen, X., et al. (2019). Corrosion Behavior of Inconel 617 in Simulated High-Temperature Boiler Environments. Corrosion Science, 142, 258-271.

International Nickel Association. (2021). Inconel Alloy 617: Properties and Applications in Extreme Environments. Technical Report Series, No. 37.

Zhang, L., & Wang, Y. (2018). Mechanical Properties and Microstructural Evolution of Inconel 617 at Elevated Temperatures. Materials Science and Engineering: A, 729, 249-258.

U.S. Department of Energy. (2022). Advanced Ultra-Supercritical Steam Cycles for Power Generation. Technical Report DOE/FE-0565.

European Boiler Manufacturers Association. (2021). Best Practices for High-Temperature Boiler Design and Material Selection. Industry Guidelines, 4th Edition.