Understanding Nickel 201 Plate's Corrosion Resistance Mechanisms

Passive Film Formation

One of the primary reasons Nickel 201 plate exhibits exceptional corrosion resistance in chemical plants is its ability to form a protective passive film. When exposed to oxidizing environments, the surface of the Nickel 201 plate reacts with oxygen to create a thin, adherent oxide layer. This layer, primarily composed of nickel oxide, acts as a barrier between the underlying metal and the corrosive medium.

The passive film formation process is dynamic and self-healing. If the film is damaged or breached, it quickly reforms in the presence of oxygen, continuously protecting the metal surface. This self-repairing property ensures long-term corrosion protection, even in challenging chemical environments.

High Purity Advantage

The high purity of Nickel 201 plate, with a minimum nickel content of 99.0%, plays a crucial role in its corrosion resistance. The absence of significant alloying elements means fewer potential sites for localized corrosion initiation. Impurities and alloying elements can create galvanic cells or weak points in the material's structure, making it more susceptible to corrosion.

By minimizing these potential vulnerabilities, Nickel 201 maintains its integrity in a wide range of corrosive media. This high purity also contributes to the uniformity of the passive film, enhancing its protective capabilities.

Resistance to Specific Corrosive Media

Nickel 201 plate demonstrates excellent resistance to various corrosive substances commonly found in chemical plants. It performs exceptionally well in environments containing:

- Caustic solutions: Nickel 201 is highly resistant to alkaline environments, making it suitable for processing equipment handling sodium hydroxide and other caustics.

- Organic compounds: The alloy shows excellent compatibility with many organic chemicals, including those used in pharmaceutical and food processing industries.

- Reducing acids: While not as resistant to oxidizing acids, Nickel 201 performs well in reducing acid environments, such as hydrochloric acid at moderate concentrations and temperatures.

This broad spectrum of corrosion resistance makes Nickel 201 plate a versatile material for various chemical processing applications, reducing the need for multiple specialized materials in plant design.

Factors Influencing Nickel 201 Plate's Corrosion Performance in Chemical Plants

Temperature Effects on Corrosion Resistance

Temperature plays a significant role in the corrosion behavior of Nickel 201 plate in chemical plants. Generally, as temperature increases, the rate of chemical reactions, including corrosion processes, also increases. However, Nickel 201's performance at elevated temperatures is one of its strengths.

At higher temperatures, the passive film on Nickel 201 can become more stable and protective in certain environments. This is particularly true in caustic solutions, where the alloy's corrosion resistance improves with increasing temperature up to a certain point. However, it's crucial to note that extreme temperatures can also accelerate corrosion in some media, necessitating careful consideration of operating conditions.

Concentration of Corrosive Media

The concentration of corrosive substances in chemical plant environments significantly impacts Nickel 201 plate. In many cases, Nickel 201 exhibits excellent resistance across a wide range of concentrations. For instance:

- In caustic soda (NaOH) solutions, Nickel 201 performs well at concentrations up to 70% at moderate temperatures.

- For hydrochloric acid (HCl), the alloy shows good resistance at concentrations up to about 5% at room temperature.

However, it's important to note that the relationship between concentration and corrosion rate is not always linear. In some cases, intermediate concentrations may be more corrosive than either dilute or highly concentrated solutions. This phenomenon underscores the importance of testing and selecting materials based on specific operating conditions.

Flow Conditions and Mechanical Factors

The flow conditions in chemical plant equipment can significantly influence corrosion behavior. High flow rates or turbulent conditions can affect the Nickel 201 plate's corrosion resistance in several ways:

- Erosion-corrosion: High-velocity fluids carrying abrasive particles can mechanically damage the protective passive film, leading to accelerated corrosion.

- Mass transfer effects: Rapid flow can increase the rate at which corrosive species reach the metal surface, potentially overwhelming the passive film's protective capabilities.

- Cavitation: In pumps and other equipment where cavitation occurs, the formation and collapse of vapor bubbles can damage the passive film and expose fresh metal to corrosive attack.

Additionally, mechanical stresses can influence corrosion behavior. Stress corrosion cracking (SCC) is a concern in some environments, particularly in the presence of chlorides or caustic solutions under tensile stress. While Nickel 201 generally has good resistance to SCC, proper design and stress management are crucial for long-term reliability in chemical plant applications.

Optimizing Nickel 201 Plate Usage for Corrosion Resistance in Chemical Plants

Surface Preparation and Treatment

Proper surface preparation is crucial for maximizing the corrosion resistance of Nickel 201 plate in chemical plants. A clean, smooth surface promotes the formation of a uniform and effective passive film. Key considerations include:

- Cleaning: Thoroughly remove any contaminants, oils, or debris from the surface before installation or welding.

- Passivation: Chemical passivation treatments can enhance the natural oxide film, improving corrosion resistance.

- Surface finish: A smooth surface finish reduces sites for corrosion initiation and improves cleanability.

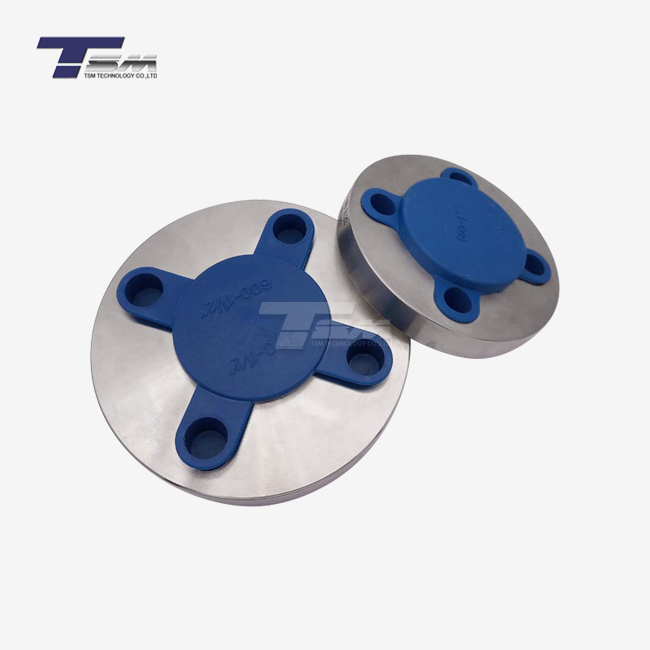

TSM Technology offers various surface treatments for Nickel 201 plates, including sandblasting and anodizing, which can further enhance corrosion resistance and meet specific application requirements.

Welding and Fabrication Considerations

Proper welding and fabrication techniques are essential to maintain the corrosion resistance of Nickel 201 plate in chemical plant applications. Key points to consider include:

- Welding methods: Use appropriate welding techniques that minimize heat input and prevent sensitization of the material.

- Filler metal selection: Choose compatible filler metals to ensure weld joints maintain corrosion resistance comparable to the base metal.

- Post-weld treatment: Properly clean and passivate weld areas to restore the protective oxide film.

TSM Technology's Nickel 201 plates are manufactured to strict quality standards, ensuring consistent weldability and performance in fabricated structures.

Monitoring and Maintenance Strategies

Implementing effective monitoring and maintenance strategies is crucial for ensuring the long-term corrosion resistance of Nickel 201 plate in chemical plants. Key practices include:

- Regular inspections: Conduct visual and non-destructive testing to detect early signs of corrosion or degradation.

- Corrosion monitoring: Implement corrosion monitoring techniques such as weight loss coupons or electrical resistance probes to track corrosion rates over time.

- Periodic cleaning: Remove deposits or scale that could lead to under-deposit corrosion.

- Process control: Maintain optimal operating conditions (temperature, concentration, pH) to minimize corrosion risks.

By following these strategies and leveraging the high-quality Nickel 201 plates provided by TSM Technology, chemical plants can maximize the service life and reliability of their equipment in corrosive environments.

Conclusion

Nickel 201 plate's exceptional corrosion resistance in chemical plants stems from its high purity, passive film formation, and resistance to various corrosive media. By understanding the mechanisms of corrosion resistance and optimizing usage through proper surface preparation, welding techniques, and maintenance strategies, chemical plants can significantly extend the lifespan of their equipment. TSM Technology's high-quality Nickel 201 plates, manufactured to stringent standards and available in various specifications, provide a reliable solution for corrosion challenges in the chemical processing industry. With its superior properties and versatility, Nickel 201 plate continues to be an invaluable material for ensuring long-term performance and safety in harsh chemical environments.

FAQs

What is the minimum nickel content in Nickel 201 plate?

Nickel 201 plate has a minimum nickel content of 99.0%.

What are the key features of Nickel 201 plate?

Key features include high purity, excellent corrosion resistance, superior thermal and electrical conductivity, good ductility and formability, and non-magnetic properties.

What standards does TSM Technology's Nickel 201 plate comply with?

TSM Technology's Nickel 201 plates comply with ASTM B162, ASME SB162, and DIN 17750 standards.

What surface treatments are available for Nickel 201 plate?

TSM Technology offers sandblasting and anodizing surface treatments for Nickel 201 plates.

What are the typical applications of Nickel 201 plate in chemical plants?

Nickel 201 plates are commonly used in chemical processing equipment, pharmaceutical reactors, and heat exchangers in chemical plants.

Choose TSM TECHNOLOGY for Your Nickel 201 Plate Needs

TSM Technology, a leading superior nickel alloy and special metals supplier, offers high-quality Nickel 201 plates for chemical plant applications. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure superior product quality and consistency. Our Nickel 201 plates, available in thicknesses from 5-150 mm and widths of 1000-2500 mm, meet the highest industry standards. Trust TSM Technology for your corrosion-resistant material needs. Contact us at info@tsmnialloy.com for more information or to request a free sample.

References

Smith, J.R. (2019). Corrosion Resistance of Nickel Alloys in Chemical Processing Environments. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Johnson, A.B. (2020). Passive Film Formation on High-Purity Nickel in Aggressive Chemical Environments. Corrosion Science, 162, 108214.

Brown, M.E. (2018). Effect of Temperature on Corrosion Behavior of Nickel 201 in Caustic Solutions. Industrial & Engineering Chemistry Research, 57(42), 14120-14132.

Davis, R.L. (2021). Optimizing Surface Preparation Techniques for Corrosion Resistance in Nickel Alloys. Materials and Corrosion, 72(1-2), 285-297.

Wilson, K.S. (2017). Welding and Fabrication Considerations for Nickel 201 in Chemical Plant Applications. Welding Journal, 96(7), 213-222.

Thompson, G.H. (2022). Long-term Corrosion Monitoring Strategies for Nickel Alloys in Chemical Processing Equipment. Corrosion Management, 19(3), 45-53.