Understanding Nickel 201 Plate Properties and Standards

Chemical Composition and Physical Properties

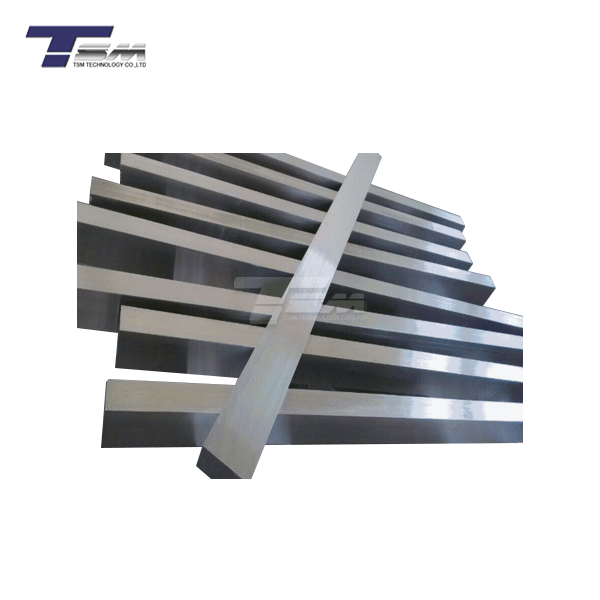

Nickel 201 plates are widely recognized for their exceptional purity, with nickel content consistently above 99.0%. This high purity contributes not only to outstanding corrosion resistance in aggressive chemical environments but also to its inherently non-magnetic nature, which is crucial for specialized applications. With a density of 8.89 g/cm³ and a melting point of 1435°C, Nickel 201 demonstrates excellent stability under elevated temperatures. Additionally, its thermal conductivity of 70 W/m·K ensures efficient heat transfer, while an electrical resistivity of 9.5 µΩ·cm provides versatility in electrical and electronic applications. These combined properties make it a reliable choice for demanding industrial settings.

Applicable Standards and Specifications

To maintain consistency and ensure reliability, Nickel 201 plates are manufactured in compliance with widely recognized international standards. The most frequently cited specifications include ASTM B162, ASME SB162, and DIN 17750. These standards define critical parameters such as chemical composition, tensile strength, hardness, and dimensional tolerances. Adhering to these specifications guarantees that each plate meets stringent quality requirements, allowing engineers and fabricators to use the material confidently in high-performance equipment. Following these standards also facilitates traceability, regulatory compliance, and global interoperability of Nickel 201 components.

Importance of Material Certification

To maintain consistency and ensure reliability, Nickel 201 plates are manufactured in compliance with widely recognized international standards. The most frequently cited specifications include ASTM B162, ASME SB162, and DIN 17750. These standards define critical parameters such as chemical composition, tensile strength, hardness, and dimensional tolerances. Adhering to these specifications guarantees that each plate meets stringent quality requirements, allowing engineers and fabricators to use the material confidently in high-performance equipment. Following these standards also facilitates traceability, regulatory compliance, and global interoperability of Nickel 201 components.

Essential Quality Verification Methods for Nickel 201 Plates

Visual Inspection and Surface Quality Assessment

A thorough visual inspection is the first step in verifying the quality of Nickel 201 plates. Look for surface defects such as scratches, pits, or discoloration that may affect the plate's performance. For plates with surface treatments like sandblasting or anodizing, ensure the finish is uniform and meets your specifications. Use appropriate lighting and magnification tools to detect any subtle imperfections that might compromise the plate's integrity.

Dimensional Accuracy Checks

Accurate dimensions are critical for many applications using Nickel 201 plates. Use precision measuring tools to verify the plate's thickness, which should fall within the 5-150 mm range, and width, typically between 1000-2500 mm. Pay close attention to flatness and straightness, as these factors can affect the plate's performance in fabrication and assembly processes. Document any deviations from the specified dimensions for further evaluation.

Non-Destructive Testing Techniques

Non-destructive testing (NDT) methods are invaluable for detecting internal flaws in Nickel 201 plates without compromising their integrity. Ultrasonic testing can reveal hidden defects, such as inclusions or voids, throughout the plate's thickness. Eddy current testing is effective for detecting surface and near-surface flaws, especially in thin plates. For critical applications, consider employing multiple NDT techniques to ensure comprehensive quality verification.

Advanced Quality Assurance Procedures for Nickel 201 Plates

Material Composition Analysis

To verify the high purity of Nickel 201 plates, conduct a detailed material composition analysis. X-ray fluorescence (XRF) spectroscopy or optical emission spectroscopy (OES) can provide accurate measurements of the nickel content and trace elements. Ensure the nickel content meets or exceeds the minimum 99.0% requirement, and check for any impurities that might affect the plate's performance in your specific application.

Mechanical Property Testing

Assess the mechanical properties of Nickel 201 plates through standardized tests. Conduct tensile tests to verify yield strength, ultimate tensile strength, and elongation. Hardness testing using methods like Brinell or Rockwell can provide additional insights into the material's properties. For applications involving cyclic loading, consider fatigue testing to ensure the plate's long-term durability. Compare the results with the specifications outlined in ASTM B162, ASME SB162, or DIN 17750 to confirm compliance.

Corrosion Resistance Evaluation

One of the key advantages of Nickel 201 plates is their excellent corrosion resistance. To verify this property, perform corrosion tests tailored to your specific application environment. Salt spray tests can simulate marine or coastal conditions, while immersion tests in various chemicals can assess resistance to specific corrosive media. For high-temperature applications, consider conducting stress corrosion cracking tests to ensure the plate's integrity under challenging conditions.

Conclusion

Verifying the quality of Nickel 201 plates is a multifaceted process that requires attention to detail and a comprehensive approach. By combining visual inspections, dimensional checks, non-destructive testing, and advanced quality assurance procedures, you can ensure that the plates meet the high standards required for demanding industrial applications. Always work with reputable suppliers who provide thorough documentation and are transparent about their quality control processes. Remember that investing time and resources in proper quality verification can prevent costly failures and ensure optimal performance of your Nickel 201 plate components.

FAQs

What are the key features of Nickel 201 plates?

Nickel 201 plates are characterized by high purity (min. 99.0% Ni), excellent corrosion resistance, superior thermal and electrical conductivity, good ductility and formability, and non-magnetic properties.

What are the common applications for Nickel 201 plates?

Nickel 201 plates are widely used in chemical processing equipment, food preparation vessels, pharmaceutical reactors, electronic components, and heat exchangers.

What standards do TSM Technology's Nickel 201 plates comply with?

TSM Technology's Nickel 201 plates comply with ASTM B162, ASME SB162, and DIN 17750 standards, ensuring consistent quality and performance.

Experience the Superior Quality of TSM Technology's Nickel 201 Plates

As a leading Nickel 201 plate manufacturer and supplier, TSM Technology combines expertise, innovation, and rigorous quality control to deliver exceptional products. Our state-of-the-art facilities, featuring 3 factories, 8 production lines, and over 100 machines, ensure consistent high-quality output. We offer customized sizes, various surface treatments, and comprehensive material certifications. Experience the difference of working with a trusted industry leader. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "ASTM B162 - Standard Specification for Nickel Plate, Sheet, and Strip."

American Society of Mechanical Engineers. (2019). "ASME SB162 - Specification for Nickel Plate, Sheet, and Strip."

Deutsches Institut für Normung. (2018). "DIN 17750 - Nickel and nickel alloy plate, sheet and strip."

ASM International. (2020). "Handbook of Corrosion-Resistant Nickel Alloys."

The American Society for Nondestructive Testing. (2022). "Nondestructive Testing Handbook: Ultrasonic Testing."

Journal of Materials Engineering and Performance. (2021). "Quality Assurance Methods for High-Performance Nickel Alloys in Industrial Applications."