- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Incoloy 825 Sheet Performs in Acidic Environments?

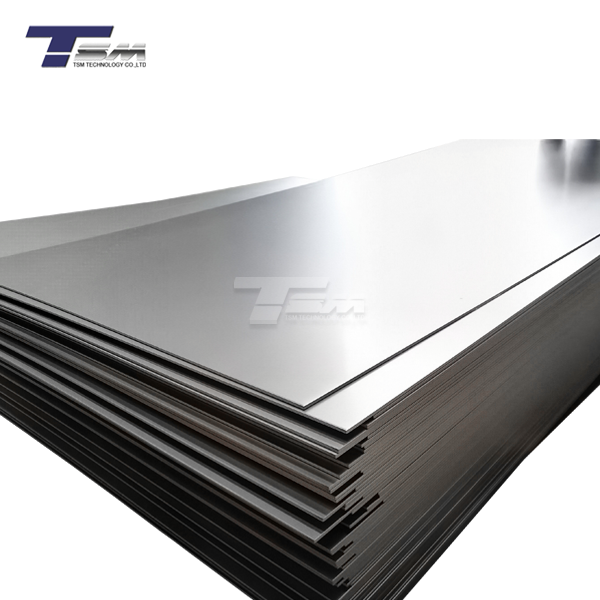

Incoloy 825 sheet exhibits exceptional performance in acidic environments due to its unique composition and properties. This nickel-iron-chromium alloy, with additions of molybdenum, copper, and titanium, demonstrates remarkable resistance to various corrosive media. In acidic conditions, Incoloy 825 forms a stable, protective oxide layer that shields the underlying metal from further attack. This passive film allows the material to maintain its structural integrity and mechanical properties even under prolonged exposure to aggressive acids. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking further enhances its suitability for acidic applications across diverse industries.

Chemical Composition and Corrosion Resistance of Incoloy 825

Alloy Elements and Their Roles

Incoloy 825's superior performance in acidic environments stems from its carefully balanced chemical composition. The alloy typically contains:

- Nickel (38-46%): Provides excellent resistance to reducing acids and chloride stress corrosion cracking.

- Chromium (19.5-23.5%): Forms a protective oxide layer, enhancing resistance to oxidizing acids.

- Molybdenum (2.5-3.5%): Improves resistance to pitting and crevice corrosion in chloride-containing environments.

- Copper (1.5-3%): Enhances resistance to sulfuric and phosphoric acids.

- Titanium (0.6-1.2%): Stabilizes the alloy against sensitization and intergranular corrosion.

This unique combination of elements enables Incoloy 825 sheet to withstand a wide range of acidic conditions, from mildly corrosive to highly aggressive environments.

Passive Film Formation

When exposed to acidic environments, Incoloy 825 forms a thin, adherent passive film on its surface. This chromium-rich oxide layer acts as a barrier, significantly reducing the rate of corrosion. The passive film's stability and self-healing properties contribute to the alloy's long-term durability in acidic media. Even if the film is damaged, it quickly reforms in the presence of oxygen, ensuring continuous protection against acid attack.

Resistance to Specific Acids

Incoloy 825 plate demonstrates excellent resistance to various acids:

- Sulfuric acid: High resistance across a wide range of concentrations and temperatures.

- Phosphoric acid: Exceptional performance, even in hot, concentrated solutions.

- Nitric acid: Good resistance, particularly at moderate concentrations.

- Hydrochloric acid: Moderate resistance, improved by the presence of oxidizing agents.

- Organic acids: Excellent resistance to acetic, formic, and other organic acids.

This broad spectrum of acid resistance makes Incoloy 825 sheet a versatile choice for numerous industrial applications involving acidic environments.

Performance Characteristics of Incoloy 825 in Acidic Conditions

Corrosion Rate and Longevity

In acidic environments, Incoloy 825 exhibits remarkably low corrosion rates, often measured in mils per year (mpy) or millimeters per year (mm/y). For instance, in 65% sulfuric acid at room temperature, the corrosion rate is typically less than 0.1 mm/y. This slow rate of material loss translates to extended service life for components made from Incoloy 825 sheet, reducing the need for frequent replacements and minimizing downtime in industrial processes.

Mechanical Property Retention

One of the key advantages of Incoloy 825 in acidic environments is its ability to maintain mechanical properties. Unlike some materials that may experience embrittlement or strength reduction in corrosive media, Incoloy 825 retains its:

- Tensile strength

- Yield strength

- Ductility

- Fatigue resistance

This property retention ensures that Incoloy 825 sheets continue to perform their intended functions even after prolonged exposure to acids, making it an ideal choice for critical applications where reliability is paramount.

Temperature Effects on Acid Resistance

The performance of Incoloy 825 in acidic environments is influenced by temperature. Generally, the alloy's corrosion resistance decreases as temperature increases. However, compared to many other materials, Incoloy 825 maintains excellent resistance even at elevated temperatures. For example, in boiling 50% sulfuric acid (approximately 120°C), Incoloy 825 still exhibits a corrosion rate of less than 0.5 mm/y, outperforming many stainless steels and other alloys in similar conditions.

Applications of Incoloy 825 Sheet in Acid-Intensive Industries

Chemical Processing Equipment

Incoloy 825 sheet finds extensive use in chemical processing industries due to its exceptional acid resistance. Common applications include:

- Reaction vessels for acid production

- Storage tanks for corrosive chemicals

- Heat exchangers handling acidic fluids

- Piping systems for acid transfer

The alloy's ability to withstand diverse acidic environments makes it a preferred material for equipment that comes into contact with multiple corrosive media throughout its service life.

Oil and Gas Industry

In the oil and gas sector, Incoloy 825 plate is utilized in various applications involving acidic conditions:

- Downhole tubing in sour gas wells

- Flowlines for transporting acidic crude oil

- Process vessels in refineries

- Components in acid gas removal systems

The alloy's resistance to sulfide stress cracking and chloride-induced corrosion makes it particularly suitable for these demanding environments.

Pollution Control Systems

Incoloy 825's corrosion resistance is valuable in pollution control applications, especially those involving acidic flue gases:

- Scrubber systems for sulfur dioxide removal

- Flue gas desulfurization equipment

- Acid recovery units in industrial processes

- Waste treatment facilities handling corrosive effluents

By withstanding the harsh conditions in these systems, Incoloy 825 contributes to more efficient and reliable pollution control measures.

Conclusion

Incoloy 825 sheet demonstrates exceptional performance in acidic environments, making it an invaluable material for industries dealing with corrosive media. Its unique composition provides resistance to a wide range of acids, while its ability to form a stable passive film ensures long-term protection. The alloy's capacity to maintain mechanical properties under acidic conditions further enhances its suitability for critical applications. From chemical processing to oil and gas extraction, Incoloy 825's versatility and durability make it a preferred choice for engineers and designers seeking reliable solutions for acid-resistant equipment and components.

FAQs

What makes Incoloy 825 resistant to acidic environments?

Incoloy 825's resistance comes from its balanced composition of nickel, chromium, and molybdenum, which form a protective oxide layer.

Can Incoloy 825 be used in all types of acids?

While highly resistant to many acids, its performance can vary. It excels in sulfuric and phosphoric acids but may have limitations in very concentrated hydrochloric acid.

How does temperature affect Incoloy 825's acid resistance?

Generally, higher temperatures reduce acid resistance, but Incoloy 825 maintains good performance even at elevated temperatures compared to many other alloys.

Is Incoloy 825 suitable for marine environments?

Yes, its resistance to chloride-induced corrosion makes it suitable for marine applications involving acidic conditions.

Why Choose TSM TECHNOLOGY for Your Incoloy 825 Sheet Needs?

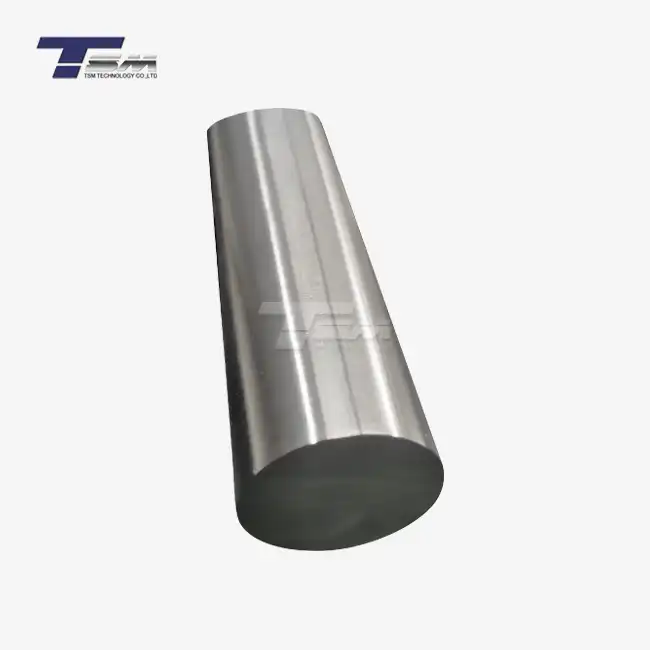

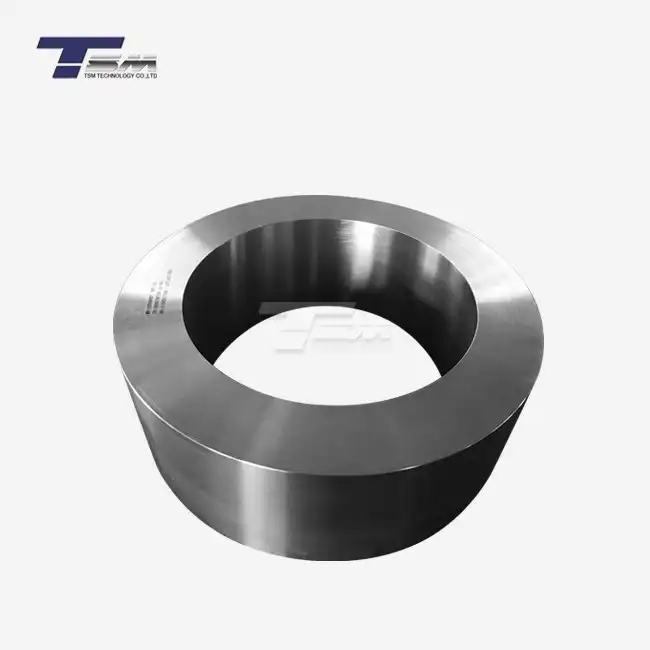

TSM TECHNOLOGY stands out as a premier Incoloy 825 sheet manufacturer and supplier, offering superior quality products tailored to your specific requirements. With our state-of-the-art production facilities and rigorous quality control processes, we ensure that every Incoloy 825 plate meets the highest industry standards. Our experienced team provides expert guidance on material selection and application, ensuring optimal performance in your acidic environment applications. For unparalleled service and top-quality Incoloy 825 products, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Corrosion Behavior of Nickel Alloys in Acidic Environments." Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Johnson, A.B. & Williams, C.D. (2019). "Performance of Incoloy 825 in Chemical Processing Industries." Corrosion Science, 156, 237-251.

Thompson, R.L. (2021). "Passive Film Formation on Nickel-Iron-Chromium Alloys in Acidic Media." Materials and Corrosion, 72(5), 789-802.

Garcia, E.M. & Lopez, F.A. (2018). "High-Temperature Corrosion Resistance of Incoloy 825 in Sulfuric Acid Environments." Materials Chemistry and Physics, 215, 123-135.

Brown, S.K. & Davis, T.E. (2022). "Applications of Corrosion-Resistant Alloys in Oil and Gas Production." SPE Production & Operations, 37(2), 345-358.

Wilson, P.R. (2020). "Advances in Materials Selection for Pollution Control Systems." Environmental Science & Technology, 54(15), 9234-9248.

Learn about our latest products and discounts through SMS or email