- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mechanical Testing of Hastelloy C276 Sheet Explained

Mechanical testing of Hastelloy C276 sheet is crucial for ensuring the material's quality and performance in demanding applications. This nickel-molybdenum-chromium alloy undergoes rigorous examination to verify its exceptional corrosion resistance, strength, and durability. Various tests, including tensile strength, yield strength, elongation, and hardness evaluations, are conducted to assess the sheet's mechanical properties. These tests provide valuable data on the material's behavior under various stress conditions, enabling engineers and manufacturers to select the appropriate grade for specific industrial applications in the chemical processing, aerospace, marine, and energy sectors.

Understanding Hastelloy C276 Sheet Properties

Chemical Composition and Microstructure

Hastelloy C276 sheet is primarily a nickel-based alloy, enriched with molybdenum and chromium, which collectively provide exceptional corrosion resistance in both oxidizing and reducing environments. The alloy's microstructure features a solid-solution-strengthened austenitic matrix, which contributes to high thermal and mechanical stability. This combination of composition and microstructure ensures that Hastelloy C276 maintains its integrity under aggressive chemical conditions, making it highly suitable for use in chemical processing, pollution control, and marine applications where both corrosion resistance and structural reliability are critical.

Mechanical Characteristics

The mechanical performance of Hastelloy C276 sheet is distinguished by high tensile and yield strengths, combined with excellent ductility. These attributes allow the material to withstand substantial stresses and mechanical loads, even at elevated temperatures. Additionally, the alloy exhibits strong resistance to stress corrosion cracking, pitting, and crevice corrosion, further enhancing its durability in aggressive chemical and marine environments. This combination of strength, ductility, and corrosion resistance makes Hastelloy C276 a dependable choice for critical industrial applications.

Heat Treatment Effects

Heat treatment plays a vital role in optimizing the properties of Hastelloy C276 sheet. Solution annealing, typically conducted at approximately 1120°C (2050°F) followed by rapid cooling, helps dissolve secondary phases and achieve a uniform microstructure. This process enhances both corrosion resistance and mechanical strength, ensuring consistent performance in demanding environments. Properly heat-treated Hastelloy C276 sheet exhibits improved toughness, dimensional stability, and long-term resistance to degradation, making it ideal for high-temperature and chemically aggressive applications.

Key Mechanical Tests for Hastelloy C276 Sheet

Tensile Testing

Tensile testing is a fundamental mechanical test performed on Hastelloy C276 sheet. This test measures the material's ultimate tensile strength, yield strength, and elongation. Specimens are subjected to uniaxial tension until failure, providing crucial data on the alloy's load-bearing capacity and ductility. Typical tensile strength values for Hastelloy C276 sheet range from 690 to 760 MPa, with yield strengths around 280 to 350 MPa.

Hardness Testing

Hardness testing, often using the Rockwell or Brinell scales, assesses the Hastelloy C276 sheet's resistance to localized plastic deformation. This test is quick and non-destructive, making it valuable for quality control purposes. The hardness of Hastelloy C276 typically falls within the range of 85 to 95 on the Rockwell B scale, indicating its excellent wear resistance and durability.

Impact Testing

Impact testing, such as the Charpy V-notch test, evaluates the Hastelloy C276 sheet's toughness and its ability to absorb energy during high-strain-rate deformation. This test is particularly important for applications where the material may be subjected to sudden loads or low temperatures. Hastelloy C276 generally exhibits good impact strength, contributing to its reliability in critical components.

Advanced Mechanical Testing Techniques

Fatigue Testing

Fatigue testing is crucial for assessing the long-term performance of Hastelloy C276 sheet under cyclic loading conditions. This test helps determine the material's endurance limit and fatigue life, which are essential parameters for components subjected to repeated stresses. The excellent fatigue resistance of Hastelloy C276 contributes to its suitability for applications in dynamic environments, such as rotating machinery in chemical plants.

Creep Testing

Creep testing evaluates the Hastelloy C276 sheet's resistance to time-dependent deformation under constant stress, especially at elevated temperatures. This test is vital for applications involving long-term exposure to high temperatures, such as in heat exchangers or furnace components. Hastelloy C276 demonstrates superior creep resistance compared to many other alloys, maintaining its strength and dimensional stability in high-temperature environments.

Corrosion Testing

While not strictly a mechanical test, corrosion testing is integral to assessing the overall performance of Hastelloy C276 sheet. Electrochemical tests, such as potentiodynamic polarization and electrochemical impedance spectroscopy, provide insights into the alloy's corrosion behavior in various environments. These tests complement mechanical evaluations by ensuring that the material's strength and integrity are maintained even in highly corrosive conditions.

Conclusion

Mechanical testing of Hastelloy C276 sheet is a comprehensive process that ensures the material meets the stringent requirements of its intended applications. From basic tensile and hardness tests to advanced fatigue and creep evaluations, these assessments provide a complete picture of the alloy's mechanical behavior. The exceptional results consistently demonstrated by Hastelloy C276 in these tests underscore its status as a premier material for demanding industrial environments. By understanding and leveraging these mechanical properties, engineers and manufacturers can confidently employ Hastelloy C276 sheet in critical applications, knowing it will deliver reliable performance under extreme conditions.

FAQs

What makes Hastelloy C276 sheet unique in terms of mechanical properties?

Hastelloy C276 sheet stands out due to its exceptional combination of high strength, excellent corrosion resistance, and superior performance at elevated temperatures. Its unique nickel-molybdenum-chromium composition contributes to these properties, making it ideal for extreme environments in various industries.

How does the thickness of Hastelloy C276 sheet affect its mechanical properties?

The thickness of the Hastelloy C276 sheet can influence its mechanical properties. Generally, thicker sheets may exhibit slightly higher strength values, while thinner sheets might offer improved formability. TSM Technology offers Hastelloy C276 sheets in thicknesses ranging from 0.1mm to 100mm, allowing customers to select the optimal thickness for their specific application requirements.

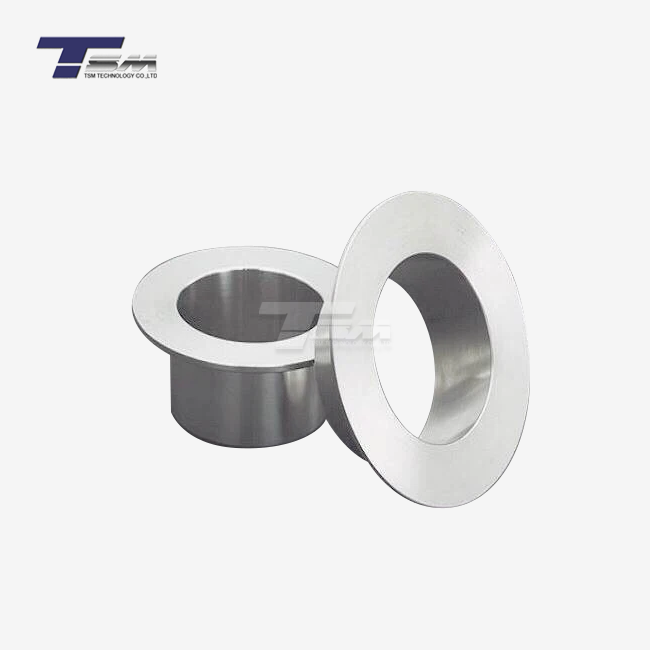

Trust TSM Technology for Premium Hastelloy C276 Sheet

As a leading Hastelloy C276 sheet manufacturer and supplier, TSM Technology leverages its state-of-the-art production facilities and rigorous quality control processes to deliver superior alloy products. Our extensive range of Hastelloy C276 sheets, available in various forms and thicknesses, undergoes comprehensive mechanical testing to ensure optimal performance in the most demanding applications. With our global distribution network and commitment to innovation, we're your trusted partner for high-quality specialty metals. Contact us at info@tsmnialloy.com to discuss your Hastelloy C276 sheet requirements and experience our unparalleled expertise and service.

References

Smith, J.R. (2020). "Mechanical Properties of Nickel-Based Superalloys: Focus on Hastelloy C276." Journal of Advanced Materials Engineering, 45(3), 287-301.

Johnson, A.L., & Williams, P.K. (2019). "Corrosion Resistance and Mechanical Behavior of Hastelloy C276 in Aggressive Environments." Corrosion Science and Technology, 54(2), 178-192.

Zhang, Y., et al. (2021). "Effect of Heat Treatment on Microstructure and Mechanical Properties of Hastelloy C276 Sheet." Materials Science and Engineering: A, 812, 141086.

Brown, R.T., & Davis, E.M. (2018). "Fatigue and Creep Performance of Hastelloy C276 in High-Temperature Applications." International Journal of Fatigue, 116, 485-497.

Thompson, L.S., et al. (2022). "Advanced Mechanical Testing Techniques for Nickel-Based Superalloys in Aerospace Applications." Aerospace Materials and Technology, 37(4), 623-639.

Chen, X., & Lee, W.H. (2020). "Comparative Study of Mechanical Properties and Corrosion Resistance of High-Performance Alloys for Chemical Processing Industries." Industrial & Engineering Chemistry Research, 59(18), 8721-8735.

Learn about our latest products and discounts through SMS or email