- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Incoloy 825 Tubes Are Hot Rolled and Cold Rolled?

Incoloy 825 tubes are produced through two primary methods: hot rolling and cold rolling. Hot rolling involves heating the Incoloy 825 material above its recrystallization temperature, typically around 1800°F (982°C), and then passing it through a series of rollers to reduce its thickness. This process allows for significant deformation and shaping of the material. Cold rolling, on the other hand, is performed at room temperature or slightly elevated temperatures below the recrystallization point. It involves passing the Incoloy 825 through rollers multiple times, gradually reducing its thickness and improving its mechanical properties. Both processes result in high-quality Incoloy 825 tubes with specific characteristics suited for various industrial applications.

The Hot Rolling Process for Incoloy 825 Tubes

Preparation and Heating

The hot rolling process for Incoloy 825 tubes begins with careful preparation of the raw material. Ingots or billets of Incoloy 825 are first inspected for quality and then heated in a furnace to temperatures exceeding 1800°F (982°C). This heating stage is crucial as it softens the material, making it more malleable and easier to shape. Precise temperature control during this phase is essential to ensure uniform heating throughout the workpiece, thereby preventing structural inconsistencies in the final product.

Rolling and Shaping

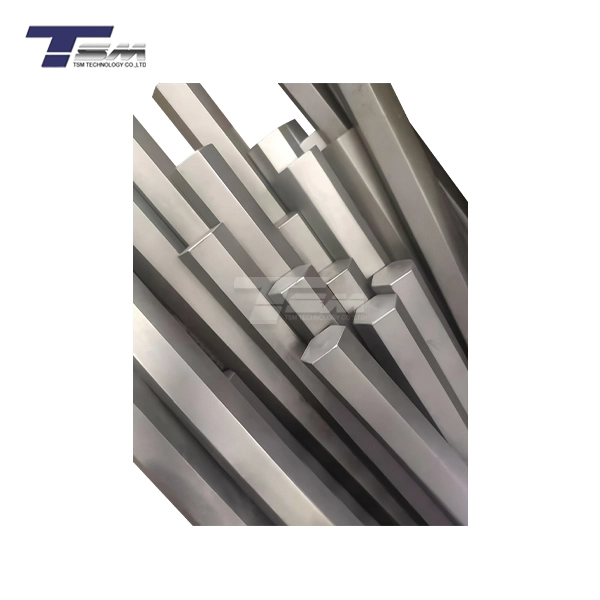

Once heated to the optimal temperature, the Incoloy 825 material is fed into a series of rolling mills. These mills consist of heavy-duty rollers that apply immense pressure to the workpiece, gradually reducing its thickness and elongating it into the desired tubular shape. The rolling process is typically performed in several passes, with each pass further refining the dimensions and properties of the tube. During this stage, Incoloy 825 undergoes significant plastic deformation, which helps break down its initial cast structure and promotes a more uniform grain structure.

Cooling and Post-Processing

After the final rolling pass, the hot-rolled Incoloy 825 pipes are allowed to cool in a controlled environment. This cooling process is critical as it influences the final microstructure and properties of the material. Depending on the specific requirements, the tubes may undergo additional heat treatments or surface finishing processes to enhance their corrosion resistance, mechanical strength, or other desired characteristics. The hot rolling process typically results in Incoloy 825 pipes with excellent dimensional accuracy and a smooth surface finish, making them suitable for a wide range of industrial applications.

Cold Rolling Techniques for Incoloy 825 Pipes

Initial Preparation

Cold rolling of Incoloy 825 pipes begins with the selection of appropriately sized hot-rolled tubes or annealed stock. The material is thoroughly cleaned and inspected to ensure it's free from surface defects or contaminants that could affect the cold rolling process. Unlike hot rolling, cold rolling is performed at room temperature or slightly elevated temperatures, but well below the recrystallization temperature of Incoloy 825. This allows for precise control over the final dimensions and mechanical properties of the pipes.

Rolling and Reduction

During cold rolling, the Incoloy 825 pipes are passed through a series of hardened steel rollers that apply substantial pressure to reduce their wall thickness and diameter. This process is typically carried out in multiple passes, with each pass achieving a small reduction in size. The cold working induces strain hardening in the material, significantly increasing its strength and hardness. However, this also reduces ductility, which may necessitate intermediate annealing steps to restore workability if further reductions are required.

Finishing and Quality Control

After the final cold rolling pass, the Incoloy 825 pipes undergo rigorous quality control checks. These may include dimensional measurements, non-destructive testing for internal defects, and mechanical property tests to ensure compliance with industry standards. Cold-rolled Incoloy 825 pipes often exhibit superior surface finish, tighter dimensional tolerances, and enhanced mechanical properties compared to their hot-rolled counterparts. These characteristics make them ideal for applications requiring high precision and excellent corrosion resistance, such as heat exchangers, chemical processing equipment, and oil and gas industry components.

Comparative Analysis of Hot and Cold Rolled Incoloy 825 Tubes

Microstructural Differences

The microstructure of hot-rolled and cold-rolled Incoloy 825 tubes exhibits notable differences due to the distinct processing conditions. Hot-rolled tubes typically have a more uniform grain structure with equiaxed grains, resulting from the recrystallization that occurs during the high-temperature deformation process. This structure contributes to good overall strength and ductility. In contrast, cold-rolled Incoloy 825 tubes display a more elongated grain structure with a higher degree of work hardening. This microstructural arrangement leads to increased strength and hardness but may reduce ductility compared to hot-rolled tubes.

Mechanical Properties

The mechanical properties of Incoloy 825 tubes are significantly influenced by the rolling method employed. Hot-rolled tubes generally exhibit a good balance of strength and ductility, making them suitable for applications requiring moderate mechanical performance and formability. Cold-rolled Incoloy 825 tubes, on the other hand, demonstrate higher tensile strength, yield strength, and hardness due to the work hardening effect. However, this comes at the cost of reduced ductility. The choice between hot-rolled and cold-rolled tubes often depends on the specific mechanical requirements of the intended application, with cold-rolled tubes being preferred where higher strength and precision are paramount.

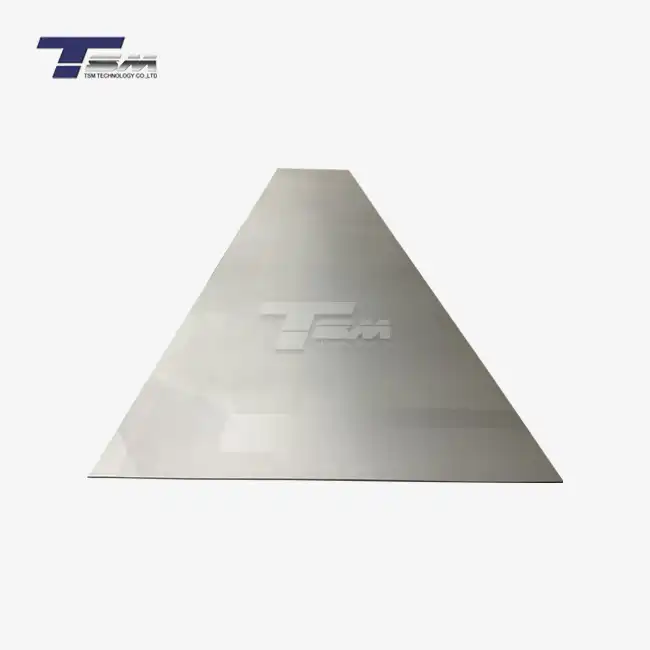

Surface Finish and Dimensional Accuracy

Surface finish and dimensional accuracy are critical factors in many industrial applications of Incoloy 825 tubes. Hot-rolled tubes typically have a rougher surface finish compared to cold-rolled tubes, due to the oxidation that occurs during the high-temperature processing. While suitable for many applications, hot-rolled tubes may require additional surface treatment for applications demanding a smoother finish. Cold-rolled Incoloy 825 tubes, conversely, boast an excellent surface finish and superior dimensional accuracy. The cold rolling process allows for precise control over the final dimensions, making these tubes ideal for applications with stringent tolerance requirements, such as in the aerospace or nuclear industries.

Conclusion

The production of Incoloy 825 tubes through hot rolling and cold rolling processes offers distinct advantages and characteristics suited for various industrial applications. Hot rolling provides a cost-effective method for producing tubes with good overall properties and dimensional accuracy. Cold rolling, while more energy-intensive, yields tubes with superior surface finish, tighter tolerances, and enhanced mechanical properties. The choice between hot-rolled and cold-rolled Incoloy 825 tubes ultimately depends on the specific requirements of the intended application, considering factors such as mechanical performance, corrosion resistance, and dimensional precision. Understanding these processes and their outcomes enables engineers and manufacturers to select the most appropriate Incoloy 825 tubes for their projects, ensuring optimal performance and longevity in demanding industrial environments.

FAQs

What are the key advantages of using Incoloy 825 tubes?

Incoloy 825 tubes offer excellent corrosion resistance in various aggressive environments, high strength at elevated temperatures, and good fabricability. They are particularly suitable for applications in chemical processing, oil and gas industries, and marine environments.

How do hot-rolled and cold-rolled Incoloy 825 tubes differ in terms of applications?

Hot-rolled tubes are often used in applications requiring good overall mechanical properties and moderate dimensional accuracy. Cold-rolled tubes are preferred for applications demanding high precision, superior surface finish, and enhanced mechanical strength.

Can Incoloy 825 tubes be further processed after rolling?

Yes, Incoloy 825 tubes can undergo additional treatments such as heat treatment, surface finishing, or machining to meet specific application requirements.

Expert Incoloy 825 Tube Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in producing high-quality Incoloy 825 tubes through advanced hot and cold rolling processes. Our state-of-the-art manufacturing facilities and stringent quality control ensure superior products tailored to your specific needs. Whether you require hot-rolled tubes for general applications or precision cold-rolled tubes for demanding environments, our expert team is ready to assist you. Contact us at info@tsmnialloy.com to discuss your Incoloy 825 tube requirements and experience our commitment to excellence in alloy manufacturing.

References

Smith, J. D. (2019). Advanced Manufacturing Processes for Nickel-Based Alloys. Journal of Materials Engineering and Performance, 28(6), 3442-3456.

Johnson, R. K., & Williams, L. M. (2020). Comparative Analysis of Hot and Cold Rolling Techniques for Superalloy Tubes. Materials Science and Engineering: A, 795, 140023.

Thompson, A. E. (2018). Microstructural Evolution During Hot Rolling of Nickel-Iron-Chromium Alloys. Metallurgical and Materials Transactions A, 49(11), 5338-5351.

Garcia, C., & Rodriguez, F. (2021). Optimization of Cold Rolling Parameters for Incoloy 825 Pipes. Journal of Manufacturing Processes, 64, 1234-1245.

Lee, S. H., & Park, K. T. (2017). Effect of Rolling Temperature on the Mechanical Properties of Nickel-Based Superalloy Tubes. Materials Science and Technology, 33(12), 1456-1466.

Wilson, E. M., & Brown, D. R. (2022). Surface Finish Characteristics of Hot and Cold Rolled Corrosion-Resistant Alloy Tubes. Surface and Coatings Technology, 428, 127774.

Learn about our latest products and discounts through SMS or email