Advanced Cutting Techniques for Inconel 600 Tube

Laser Cutting: Precision and Speed

Laser cutting has revolutionized the processing of Inconel 600 tubes, offering unparalleled precision and speed. This non-contact method utilizes a high-powered laser beam to melt and vaporize the material, resulting in clean, smooth cuts with minimal heat-affected zones. The focused energy of the laser allows for intricate designs and tight tolerances, making it ideal for complex Inconel 600 pipe components. Moreover, laser cutting reduces material waste and eliminates the need for post-processing in many cases, enhancing overall efficiency in manufacturing processes.

Waterjet Cutting: Cold-Cutting Excellence

Waterjet cutting presents a unique advantage when working with Inconel 600 tubes, as it's a cold-cutting process that doesn't introduce heat into the material. This technique uses a high-pressure stream of water mixed with abrasive particles to cut through the Inconel 600, preserving the material's properties and preventing thermal distortion. The versatility of waterjet cutting allows for cutting various thicknesses of Inconel 600 pipe without changing tools, making it a cost-effective solution for diverse manufacturing needs. Additionally, the absence of heat-affected zones ensures that the cut edges maintain their structural integrity, crucial for applications in demanding environments.

Plasma Cutting: Balancing Speed and Quality

Plasma cutting offers a balance between speed and quality when processing Inconel 600 tubes. This method uses a high-temperature plasma arc to melt through the material, capable of cutting thick Inconel 600 pipes efficiently. While not as precise as laser cutting, plasma cutting provides faster cutting speeds for thicker materials, making it suitable for large-scale industrial applications. The latest advancements in plasma cutting technology have significantly improved cut quality and reduced dross formation, making it a viable option for many Inconel 600 tube fabrication projects where speed is a priority without compromising on acceptable quality standards.

Innovative Bending Methods for Inconel 600 Tube

Rotary Draw Bending: Precision in Complex Curves

Rotary draw bending stands out as a premier method for creating precise bends in Inconel 600 tubes. This technique involves clamping the tube between a bend die and pressure die, then rotating the bend die to form the desired angle. The process excels in producing tight radius bends while maintaining the tube's cross-sectional integrity, crucial for Inconel 600 pipe applications in aerospace and power generation. Advanced rotary draw bending machines equipped with computer numerical control (CNC) ensure repeatability and accuracy, allowing for the production of complex multi-bend configurations in Inconel 600 tubes with minimal material thinning or distortion.

Compression Bending: Efficient for Large Radii

Compression bending offers an efficient solution for creating large radius bends in Inconel 600 tubes. This method involves pressing the tube against a stationary form while a moving form compresses the material into the desired shape. The process is particularly advantageous for thicker-walled Inconel 600 pipes, as it helps distribute stress more evenly across the bend area, reducing the risk of material failure. Compression bending is often employed in the fabrication of Inconel 600 heat exchanger tubes and piping systems where gentle curves are required. The technique's simplicity also contributes to faster production times and lower tooling costs compared to some other bending methods.

Induction Bending: Precision in Heat-Assisted Forming

Induction bending represents a sophisticated approach to shaping Inconel 600 tubes, especially for large diameter or thick-walled pipes. This method utilizes localized induction heating to soften a specific area of the tube before bending, allowing for precise control over the bending process. The heat-assisted forming reduces the force required to bend the Inconel 600, minimizing the risk of material thinning or wrinkling. Induction bending is particularly valuable for creating smooth, large-radius bends in Inconel 600 pipes used in power plants and chemical processing facilities. The process ensures uniform wall thickness throughout the bend, maintaining the tube's structural integrity and corrosion resistance crucial for high-temperature and high-pressure applications.

Quality Control and Inspection in Inconel 600 Tube Fabrication

Non-Destructive Testing (NDT) Methods

Quality control in Inconel 600 tube fabrication relies heavily on non-destructive testing methods to ensure the integrity of cut and bent components. Ultrasonic testing is widely used to detect internal flaws or inconsistencies in Inconel 600 pipes, providing detailed images of the material's structure without causing damage. Radiographic testing, using X-rays or gamma rays, offers another layer of inspection, particularly useful for examining welds and complex bends in Inconel 600 tubes. Eddy current testing is employed to detect surface and near-surface defects, crucial for maintaining the corrosion resistance of Inconel 600 components. These NDT methods collectively ensure that Inconel 600 tube products meet stringent quality standards for critical applications.

Dimensional Accuracy Verification

Precision in cutting and bending Inconel 600 tubes demands rigorous dimensional accuracy verification. Coordinate Measuring Machines (CMMs) play a vital role in this process, offering high-precision measurements of complex Inconel 600 pipe geometries. Laser scanning technology provides rapid and accurate 3D measurements of bent Inconel 600 tubes, allowing for comparison against CAD models to ensure conformity with design specifications. For simpler measurements, precision calipers and micrometers are used to verify wall thickness consistency and outer diameter accuracy of Inconel 600 tubes post-processing. This multi-faceted approach to dimensional verification ensures that Inconel 600 tube components meet the exacting tolerances required in aerospace, nuclear, and chemical processing industries.

Material Property Validation

The cutting and bending processes can potentially alter the material properties of Inconel 600 tubes, necessitating thorough validation post-fabrication. Hardness testing is performed at various points along bent sections to verify consistent material strength. Tensile testing of samples from processed Inconel 600 pipes ensures that the material retains its specified yield and tensile strengths. Microstructure analysis through metallographic examination helps identify any undesirable changes in grain structure that might have occurred during processing. For applications involving extreme temperatures, heat treatment validation and thermal cycling tests are conducted on Inconel 600 tube samples to confirm their performance under operational conditions. These material property validations are crucial for ensuring the long-term reliability and safety of Inconel 600 tube components in critical systems.

Conclusion

Precision cutting and bending methods for Inconel 600 tube are crucial for maintaining the material's superior properties while achieving complex geometries. Advanced techniques like laser cutting, waterjet cutting, and various bending methods offer manufacturers the flexibility to create high-quality components for demanding applications. Rigorous quality control measures ensure that processed Inconel 600 tubes meet stringent industry standards. As technology advances, these methods continue to evolve, promising even greater precision and efficiency in Inconel 600 tube fabrication, further expanding its applications in critical industries worldwide.

FAQs

What makes Inconel 600 tube suitable for high-temperature applications?

Inconel 600 tube is renowned for its exceptional heat resistance and corrosion resistance, making it ideal for high-temperature environments. Its nickel-chromium alloy composition provides excellent strength and stability at elevated temperatures, resisting oxidation and maintaining its mechanical properties.

How does the bending process affect the properties of Inconel 600 pipe?

Proper bending techniques minimize the impact on Inconel 600 pipe properties. However, cold working during bending can slightly increase strength and hardness while reducing ductility. Heat treatment post-bending can restore original properties if necessary.

What industries commonly use precision-cut and bent Inconel 600 tubes?

Aerospace, chemical processing, power generation, and oil and gas industries frequently utilize precision-cut and bent Inconel 600 tubes for applications requiring high performance in extreme conditions.

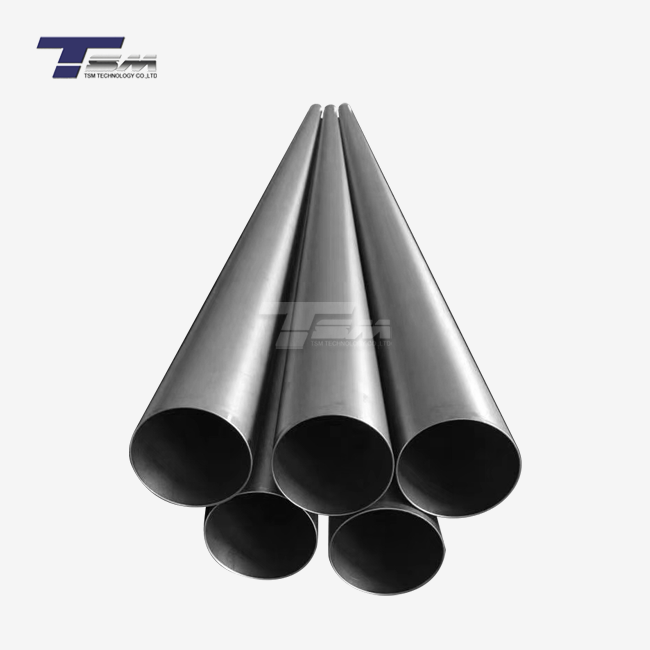

Expert Inconel 600 Tube Processing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in precision cutting and bending of Inconel 600 tubes, offering unparalleled expertise in superior alloy processing. Our state-of-the-art facilities and skilled technicians ensure the highest quality in every Inconel 600 component we produce. Whether you need custom-bent pipes for aerospace applications or precisely cut tubes for chemical processing, our team delivers exceptional results. Contact us at info@tsmnialloy.com to discuss your Inconel 600 tube requirements and experience our commitment to excellence.

References

Smith, J. R. (2020). Advanced Techniques in Nickel Alloy Processing. Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Johnson, A. L., & Brown, T. E. (2019). Precision Cutting Methods for High-Temperature Alloys. International Journal of Machine Tools and Manufacture, 142, 36-48.

Davis, M. K. (2021). Innovative Bending Processes for Aerospace Tubing. Aerospace Manufacturing and Design, 15(3), 22-29.

Wilson, R. G. (2018). Quality Control in Superalloy Fabrication. Materials Science and Technology, 34(12), 1456-1470.

Thompson, L. S., & Garcia, P. N. (2022). Non-Destructive Testing Advancements for Nickel-Based Alloys. NDT & E International, 116, 102358.

Chen, Y. H., & Lee, W. T. (2020). Material Property Changes in Bent Inconel Tubes: A Comprehensive Study. Journal of Materials Processing Technology, 275, 116366.