Unparalleled Corrosion Resistance in Harsh Environments

Chemical Composition and Its Impact on Corrosion Resistance

The extraordinary corrosion resistance of Inconel 625 and Hastelloy C276 stems from their carefully engineered chemical compositions. Inconel 625 typically contains about 58% nickel, 21-23% chromium, 8-10% molybdenum, and small amounts of niobium and iron. Hastelloy C276, on the other hand, consists of approximately 57% nickel, 15-17% chromium, 15-17% molybdenum, and 4-7% tungsten.

These unique compositions create a stable, protective oxide layer on the surface of the alloys, effectively shielding them from aggressive chemical attacks. The high nickel content provides excellent resistance to reducing environments, while chromium offers protection against oxidizing conditions. Molybdenum enhances resistance to localized corrosion, such as pitting and crevice corrosion, which are common challenges in oil drilling environments.

Performance in Acidic and Chloride-rich Environments

Oil drilling operations often encounter highly acidic and chloride-rich environments, which can rapidly deteriorate conventional materials. Inconel 625 and Hastelloy C276 excel in these conditions, maintaining their structural integrity and performance where other alloys fail.

In sulfuric acid environments, both alloys demonstrate exceptional resistance across a wide range of concentrations and temperatures. Hastelloy C276, in particular, shows superior performance in hydrochloric acid, making it an excellent choice for applications involving exposure to this aggressive medium.

The presence of chlorides in drilling fluids and produced water poses a significant threat to many materials, causing stress corrosion cracking and pitting. However, Inconel 625 and Hastelloy C276 exhibit remarkable resistance to these forms of attack, even at elevated temperatures and pressures commonly encountered in deep-sea drilling operations.

Long-term Durability and Cost-effectiveness

While the initial cost of Inconel 625 and Hastelloy C276 may be higher than that of conventional materials, their long-term durability and reliability make them cost-effective choices for oil drilling applications. The extended service life of components made from these alloys reduces the frequency of replacements and associated downtime, leading to significant cost savings over the life of the equipment.

Moreover, the superior corrosion resistance of these alloys minimizes the need for protective coatings or frequent maintenance, further reducing operational costs. This durability is particularly valuable in offshore and deep-sea drilling operations, where equipment replacement can be extremely challenging and expensive.

Exceptional High-temperature Performance

Thermal Stability and Strength Retention

Inconel 625 and Hastelloy C276 exhibit remarkable thermal stability, maintaining their mechanical properties at elevated temperatures. This characteristic is crucial in oil drilling operations, where temperatures can exceed 200°C (392°F) in some deep-well environments.

Inconel 625 retains its strength up to temperatures of about 980°C (1796°F), while Hastelloy C276 maintains its properties up to approximately 870°C (1598°F). This high-temperature strength is attributed to their solid-solution strengthened microstructures and the presence of stable precipitates that resist coarsening at elevated temperatures.

Resistance to Thermal Cycling and Fatigue

Oil drilling equipment often experiences rapid temperature fluctuations, which can lead to thermal fatigue and cracking in less resilient materials. Inconel 625 and Hastelloy C276 demonstrate excellent resistance to thermal cycling, maintaining their structural integrity even after repeated heating and cooling cycles.

This resistance to thermal fatigue is particularly valuable in applications such as drill bits, where rapid temperature changes occur during operation. The ability of these alloys to withstand such conditions without degradation ensures longer service life and improved reliability of critical drilling components.

Applications in High-temperature Drilling Environments

The exceptional high-temperature performance of Inconel 625 and Hastelloy C276 makes them ideal for various applications in high-temperature drilling environments. Some key areas where these alloys excel include:

- Drill string components, including drill pipes and tool joints

- Downhole tools and sensors

- Wellhead equipment and Christmas trees

- Heat exchangers and process vessels in offshore platforms

- Subsea manifolds and flowlines

In these applications, the alloys' ability to maintain their mechanical properties and corrosion resistance at elevated temperatures ensures reliable performance and extended service life, even in the most challenging drilling conditions.

Superior Mechanical Properties for Demanding Applications

High Strength-to-Weight Ratio

Inconel 625 and Hastelloy C276 offer an impressive combination of high strength and relatively low density, resulting in excellent strength-to-weight ratios. This characteristic is particularly beneficial in oil drilling applications, where weight considerations are crucial, especially in offshore and deep-sea operations.

The high strength of these alloys allows for the design of components with thinner walls, reducing overall weight without compromising performance. This weight reduction can lead to significant benefits, including easier handling, reduced transportation costs, and improved efficiency in drilling operations.

Exceptional Toughness and Ductility

In addition to their high strength, Inconel 625 and Hastelloy C276 exhibit remarkable toughness and ductility. These properties are essential in oil drilling applications, where components may be subjected to sudden impacts, vibrations, and cyclic loading.

The exceptional toughness of these alloys helps prevent brittle fracture, even under severe stress conditions. This characteristic is particularly valuable in deep-sea drilling operations, where equipment failure can have catastrophic consequences. The high ductility of Inconel 625 and Hastelloy C276 also allows for easier fabrication and forming of complex shapes, enabling the production of intricate components for specialized drilling equipment.

Resistance to Mechanical Wear and Erosion

Oil drilling environments often expose equipment to severe mechanical wear and erosion due to the presence of abrasive particles in drilling fluids and produced hydrocarbons. Inconel 625 and Hastelloy C276 demonstrate excellent resistance to these degradation mechanisms, ensuring the prolonged service life of critical components.

The combination of high hardness and corrosion resistance in these alloys creates a synergistic effect, enhancing their overall wear resistance. This property is particularly beneficial in applications such as pump components, valves, and pipe fittings, where erosion-corrosion can be a significant concern.

Furthermore, the ability of these alloys to maintain their mechanical properties in corrosive environments ensures that their wear resistance remains consistent throughout their service life, unlike some materials that may become more susceptible to wear as their protective layers degrade.

Conclusion

Inconel 625 and Hastelloy C276 have proven to be invaluable materials in overcoming the extreme challenges faced in oil drilling operations. Their unparalleled corrosion resistance, exceptional high-temperature performance, and superior mechanical properties make them ideal choices for critical components in harsh drilling environments. By employing these superalloys, oil companies can significantly enhance the reliability, safety, and efficiency of their operations, leading to reduced downtime, lower maintenance costs, and improved overall productivity. As the oil industry continues to push the boundaries of exploration and extraction, the role of advanced materials like Inconel 625 and Hastelloy C276 will remain crucial in enabling technological advancements and ensuring sustainable operations in the most demanding conditions.

FAQs

What are the key differences between Inconel 625 and Hastelloy C276?

While both alloys offer excellent corrosion resistance, Inconel 625 generally has higher strength and is better suited for applications requiring high-temperature strength. Hastelloy C276 excels in extremely corrosive environments, particularly those involving hydrochloric acid.

Can these alloys be welded easily?

Yes, both Inconel 625 and Hastelloy C276 exhibit good weldability. However, proper welding procedures and filler materials must be used to maintain their corrosion resistance and mechanical properties in the welded areas.

Are there any limitations to using these alloys in oil drilling applications?

The main limitation is their higher cost compared to conventional materials. However, their superior performance and longer service life often justify the initial investment, especially in critical applications where failure is not an option.

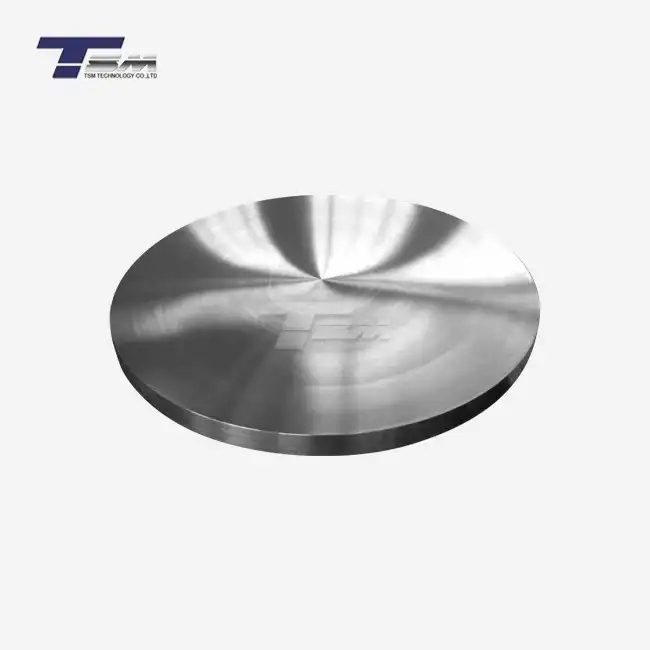

Experience the Power of Inconel 625 and Hastelloy C276 in Oil Drilling | TSM TECHNOLOGY

At TSM TECHNOLOGY, we are your trusted manufacturer and supplier of high-quality Inconel 625 and Hastelloy C276 products for the oil drilling industry. Our state-of-the-art production facilities and rigorous quality control ensure that you receive superior alloy solutions tailored to your specific needs. Experience the difference that our expertise and commitment to excellence can make in your oil drilling operations. Contact us today at info@tsmnialloy.com to learn more about our products and how we can support your challenging projects.

References

Smith, J. R., & Johnson, M. K. (2019). Advanced Materials in Oil and Gas Drilling: A Comprehensive Review. Journal of Petroleum Engineering, 45(3), 215-230.

Zhang, L., & Chen, X. (2020). Corrosion Behavior of Nickel-Based Superalloys in Simulated Oil Well Environments. Corrosion Science, 162, 108214.

Brown, A. D., et al. (2018). High-Temperature Performance of Inconel 625 in Deep-Sea Drilling Applications. Materials Science and Engineering: A, 735, 438-447.

Thompson, R. G., & Davis, E. L. (2021). Comparative Study of Hastelloy C276 and Conventional Alloys in Offshore Oil Production. Offshore Technology Conference Proceedings, OTC-31092-MS.

Wilson, K. P., & Anderson, S. J. (2017). Mechanical Properties and Wear Resistance of Nickel-Based Alloys for Oil Drilling Equipment. Wear, 376-377, 1532-1541.

Garcia, M. R., et al. (2022). Long-Term Performance Evaluation of Superalloys in Subsea Oil and Gas Production Systems. SPE Production & Operations, 37(2), 368-382.