Superior Corrosion Resistance in Aggressive Chemical Environments

Unparalleled Protection Against Acids and Alkalis

Nickel alloy plates exhibit exceptional resistance to a wide range of corrosive media commonly encountered in chemical processing. These advanced materials can withstand exposure to concentrated sulfuric acid, hydrochloric acid, and caustic solutions without significant degradation. The inherent nobility of nickel, combined with carefully selected alloying elements, creates a stable passive layer that shields the underlying metal from attack. This remarkable corrosion resistance allows for the construction of durable vessels, tanks, and piping systems that maintain their integrity even when handling highly aggressive chemicals.

Resistance to Stress Corrosion Cracking

One of the most critical advantages of nickel alloy sheets in chemical processing is their superior resistance to stress corrosion cracking (SCC). This insidious form of corrosion, which can lead to catastrophic failure in other materials, is effectively mitigated in nickel alloys. The unique microstructure and composition of these alloys prevent the initiation and propagation of stress corrosion cracks, even under simultaneous exposure to tensile stresses and corrosive environments. This property is particularly valuable in pressurized systems and equipment subject to cyclic loading, ensuring long-term reliability and safety in chemical plant operations.

Enhanced Pitting and Crevice Corrosion Resistance

Nickel alloy sheets demonstrate exceptional resistance to localized forms of corrosion, such as pitting and crevice corrosion. These types of attack can be particularly problematic in chemical processing environments where chlorides or other halides are present. The high nickel content, often supplemented with chromium and molybdenum, creates a robust barrier against the initiation and growth of pits. This resistance to localized corrosion is crucial for maintaining the integrity of heat exchanger tubes, valve components, and other critical parts exposed to stagnant or low-flow conditions where these forms of corrosion are most likely to occur.

High-Temperature Strength and Stability

Exceptional Creep Resistance at Elevated Temperatures

Nickel alloy plates maintain their strength and structural integrity at high temperatures, a property that is invaluable in chemical processing applications involving elevated operating conditions. The face-centered cubic crystal structure of nickel, along with carefully selected alloying elements, provides excellent creep resistance. This means that nickel alloy components can withstand prolonged exposure to high stresses at elevated temperatures without experiencing significant deformation or failure. For instance, nickel alloy heat exchanger tubes can operate reliably in processes running at temperatures exceeding 1000°C, far beyond the capabilities of conventional stainless steels.

Thermal Stability and Resistance to Oxidation

The thermal stability of nickel alloy sheets is another key factor in their preference for chemical processing industries. These materials maintain their mechanical properties and corrosion resistance even after long-term exposure to high temperatures. Moreover, nickel alloys form a tenacious, adherent oxide layer when exposed to high-temperature oxidizing environments. This protective scale prevents further oxidation of the underlying metal, ensuring the longevity of components in applications such as furnace parts, flue gas handling systems, and high-temperature reactors. The combination of thermal stability and oxidation resistance allows for the design of equipment with extended service life and reduced maintenance requirements.

Resistance to Thermal Cycling and Fatigue

Chemical processing often involves cyclic temperature changes, which can lead to thermal fatigue in less capable materials. Nickel alloy sheets excel in these conditions due to their excellent resistance to thermal cycling and fatigue. The low coefficient of thermal expansion of many nickel alloys, coupled with their high thermal conductivity, minimizes thermal stresses during heating and cooling cycles. This property is particularly important in applications such as catalytic reformers, where rapid temperature fluctuations are common. The ability to withstand repeated thermal cycling without degradation or crack formation ensures the long-term reliability of critical components in chemical processing plants.

Versatility and Fabrication Advantages

Excellent Weldability and Formability

Nickel alloy sheets offer exceptional fabrication characteristics, making them ideal for constructing complex chemical processing equipment. These materials exhibit excellent weldability, allowing for the creation of strong, corrosion-resistant joints using various welding techniques such as TIG, MIG, and resistance welding. The high ductility of nickel alloys also facilitates cold forming operations, enabling the manufacture of intricate shapes and components without compromising material properties. This versatility in fabrication allows engineers to design and construct chemical processing equipment with optimal performance and efficiency.

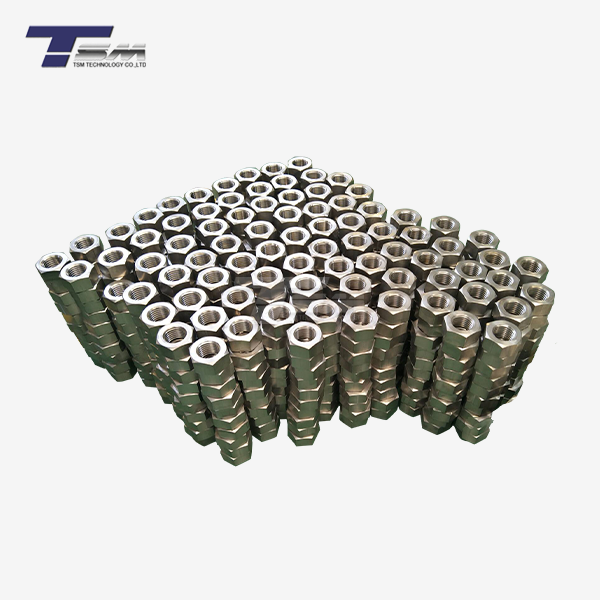

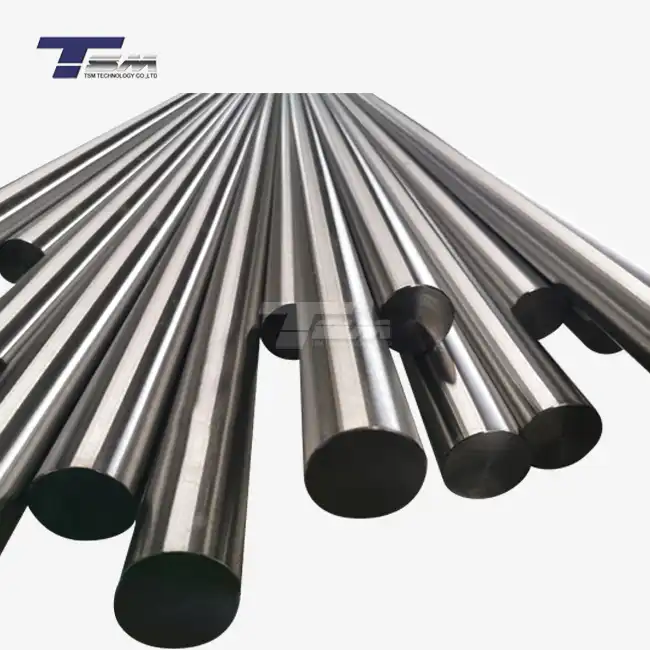

Wide Range of Available Grades and Forms

The nickel alloy family encompasses a diverse range of compositions, each tailored to specific application requirements. From corrosion-resistant alloys like Hastelloy and Inconel to high-temperature alloys like Incoloy, there's a nickel alloy grade suited for virtually every chemical processing challenge. These alloys are available in various forms, including sheets, plates, coils, and foils, with thicknesses ranging from 0.1 mm to 100 mm. This wide selection allows for precise material selection based on the specific corrosion, temperature, and mechanical requirements of each application, ensuring optimal performance and cost-effectiveness in chemical plant design.

Customizable Surface Finishes and Treatments

Nickel alloy sheets can be further enhanced through various surface treatments and finishes to meet specific application needs. Options such as 2B/BA surface finishes with Ra ≤0.8μm, sandblasting, pickling, and electrolytic polishing allow for tailored surface properties. These treatments can improve corrosion resistance, reduce fouling, or enhance heat transfer efficiency in chemical processing equipment. Additionally, advanced heat treatment processes like solution annealing and stress relief annealing can be applied to optimize the mechanical properties and stress state of fabricated components. This level of customization ensures that nickel alloy sheets can be precisely engineered to meet the demanding requirements of modern chemical processing industries.

Conclusion

Nickel alloy plates have established themselves as the gold standard in chemical processing industries due to their unparalleled combination of corrosion resistance, high-temperature performance, and fabrication versatility. Their ability to withstand aggressive chemical environments while maintaining structural integrity at elevated temperatures makes them indispensable for critical applications. The wide range of available grades, coupled with customizable properties, allows for tailored solutions to specific processing challenges. As the chemical industry continues to evolve, nickel alloy sheets will undoubtedly remain at the forefront of material selection, driving innovation and ensuring the safety, efficiency, and reliability of chemical processing operations worldwide.

FAQs

What are the most common nickel alloys used in chemical processing?

Common nickel alloys include Hastelloy, Inconel, and Monel, each designed for specific corrosive environments.

How do nickel alloy sheets compare to stainless steel in chemical resistance?

Nickel alloys generally offer superior resistance to a broader range of chemicals and higher temperatures compared to stainless steels.

Can nickel alloy sheets be used in food processing applications?

Yes, certain nickel alloys are suitable for food processing due to their corrosion resistance and compliance with food safety regulations.

Experience the Superior Performance of Nickel Alloy Sheets | TSM TECHNOLOGY

At TSM Technology, a premier nickel alloy sheets manufacturer, we specialize in delivering high-quality nickel alloy sheets tailored to the exacting needs of chemical processing industries. Our advanced manufacturing capabilities, including precision rolling and heat treatment, ensure optimal material properties for your specific application. With a wide range of alloy grades and customizable specifications, we provide solutions that excel in the most demanding environments. Contact our expert team at info@tsmnialloy.com to discover how our nickel alloy sheets can enhance the performance and longevity of your chemical processing equipment.

References

Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International.

Crook, P. (2005). Corrosion Resistance of Nickel Alloys in Chemical Process Industries. NACE International.

Mankins, W.L. & Lamb, S. (1990). Nickel and Nickel Alloys. ASM Handbook, Vol. 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

Rebak, R.B. (2011). Nickel Alloys for Corrosive Environments. The UHLIG Corrosion Handbook, 3rd Edition.

Totemeier, T.C. & Lillo, T.M. (2005). Effect of Orientation on the Tensile and Creep Properties of Coarse-Grained Nickel-Based Superalloy Sheets. Metallurgical and Materials Transactions A.

Special Metals Corporation. (2007). High-Performance Alloys for Resistance to Aqueous Corrosion. Special Metals Corporation Publication Number SMC-026.