The K500 Monel bar is an example of the best engineering ever in nickel-copper alloy technology. It uses precipitation hardening and has better resistance to rust than other bars, which makes it the best choice for very important uses. Making this specialized metal is a complex process that includes vacuum induction melting, careful mixing of aluminum and titanium, controlled hot working, and age-hardening heat methods that give the metal a tensile strength of over 1100 MPa. This detailed manufacturing process, along with strict quality checks and adherence to licensing standards, guarantees that procurement professionals get materials that can survive the toughest conditions in the aerospace, marine, oil and gas, and power generation industries.

Understanding Monel K500 Bar and Its Key Properties

Monel K500 has a unique precipitation-hardened texture that makes it different from other nickel-copper alloys. Monel 400 is usually made stronger through solid-solution strengthening, but the K500 version can be made harder through age-hardening because it has aluminum and titanium added to it. Because of this important difference, the material can reach tensile strengths of 1100–1350 MPa, while Monel 400 usually only gets 550–750 MPa.

Chemical Composition and Microstructural Advantages

The metal is usually made up of 63–70% nickel and 28–34% copper, along with 2.3–3.15% aluminum and 0.35–0.85% titanium, which are added in carefully controlled amounts. During heat treatment, these elements form intermetallic precipitates that make the matrix stronger while keeping the great corrosion protection that nickel-copper alloys have by nature. The microstructure that was created has an amazing ability to prevent stress-corrosion cracks. This is especially true in places with a lot of chloride, where stainless steels usually fail.

Superior Performance Characteristics

For uses that need a mix of mechanical power and environmental protection, this alloy is always picked by material engineers. Because it isn't magnetic, it's very useful in delicate electrical settings, and because it's 8.44 g/cm³ dense, it has the best strength-to-weight ratio. Its great resistance to seawater makes it useful for marine uses, with virtually no measured corrosion rates in long exposure tests.

Step-by-Step Breakdown of Monel K500 Bar Manufacturing Process

Choosing the right raw materials and every step of the production process are both important for making great products. Our knowledge of metallurgy guarantees that the manufacturing process always has the same high standard.

Primary Melting and Alloy Development

VIM, or vacuum induction melting, is the basis of quality output. This process gets rid of air pollution and allows for exact control of the chemicals that are used. During melting, a controlled vacuum with a pressure of about 10⁻³ to 10⁻⁴ torr is used to keep the metal from oxidizing and make sure that it is evenly distributed. Controlling the temperature during melting keeps the flow at the right level and stops the alloying elements from separating.

Casting and Initial Forming Operations

After it melts, the alloy is made either continuously or in ingots, which depends on what the finished product needs. Ingot casting makes bigger cross-sections possible, but continuous casting gives better surface quality and dimensional stability. The cooling rate and mold temperature are casting factors that have a direct effect on grain structure and on mechanical traits.

Hot Working and Mechanical Processing

When the temperature is between 1000°C and 1150°C, hot forging improves the grain of the cast and gets rid of problems with the casting for K500 monel bar. The controlled compression helps the alloying elements spread out evenly while breaking down the coarse grain structures. Hot rolling later on keeps the temperature steady to stop work hardening and lower the cross-sectional area. These thermal-mechanical steps create a solid base for the best reaction to heat treatment.

Heat Treatment of Monel K500 Bar – Process and Benefits

By carefully applying heat in a number of steps, the manually worked material is turned into a high-performance metal. Procurement experts can set the right material conditions for different uses when they understand how these processes work.

Solution Annealing Parameters and Objectives

Solution annealing happens at temperatures between 980°C and 1065°C. The material is usually kept at this temperature for long enough to make sure that all of the elements that form precipitates are dissolved. This process at a high temperature makes the material more uniform and gets rid of internal stresses from work that was done before. Rapid cooling, which is usually done by water chilling, keeps the supersaturated solid solution that is needed for precipitation hardening.

Precipitation Hardening (Age Hardening) Process

The material's unique strength qualities are created by age hardening it at temperatures between 700°C and 760°C for 16 to 20 hours. During this process, precipitates of gamma prime (γ′) form all over the matrix. These make it much harder for dislocations to move, which makes the material much stronger. Hardness readings can keep an eye on the precipitation process. The best results are seen when the size and spread of the precipitate reach equilibrium.

Property Development and Quality Verification

After being heated, the yield strength is more than 160 ksi (1103 MPa), and the stretch value is 15% or more. This metal stays resistant to corrosion during the strengthening process. This is different from stainless steels that are hardened by precipitation, which often lose their ability to resist corrosion in order to gain better mechanical qualities. Verification testing uses standard test methods to check both rust resistance and tensile strength according to ASTM standards.

Comparison and Selection Guidance: Monel K500 Bar vs Other Alloys

To choose a material, you need to know a lot about how different metal systems work. Through close comparison, the k500 Monel bar's one-of-a-kind benefits can be seen.

Performance Against Stainless Steel Alternatives

K500 Monel bar is better at resisting chloride stress-corrosion cracks than duplex and super-duplex stainless steels. Even though stainless steels might be cheaper at first, they are more likely to get localized corrosion in naval settings, which usually makes them more expensive overall. Monel K500 isn't magnetic, which gives it more benefits in situations where magnetic disturbance needs to be reduced.

Evaluation Against Inconel and Other Nickel Alloys

Inconel alloys work best in settings that get very hot and oxidizing. They don't harden as much as K500 does when it rains at normal service temps. While cupronickel metals work well in seawater, they aren't as strong as precipitation-hardened Monel. This one-of-a-kind mix makes K500 the best pick for uses that need to be strong and resistant to rust.

Ensuring Quality and Reliability: Certifications and Supplier Selection

Quality assurance looks beyond the materials used and includes the steps taken to make the product, the ways used to test it, and making sure that the product meets the standards set by the industry. Choosing sellers with proven skills and strong quality systems is key to procurement success.

International Standards Compliance and Certification

To make sure that people all over the world will use our goods, TSM Technology follows the ASTM B865, ASME SB865, and EN 10095 standards. We are dedicated to the highest quality standards, as shown by our AS9100D aerospace approval. Our compliance with ISO 9001 ensures consistent quality control across all activities. Material test certificates (MTC) and SGS proof are two more ways to make sure that the product meets the requirements.

Our manufacturing plant covers 50,000 square meters, and there are three companies with over 100 specialized tools on eight production lines. With this infrastructure in place, 300 tons of product can be made every month, and quality control can be maintained all the way through the process. Before each production run, chemical analysis, mechanical property proof, and dimensional checking are done.

Supplier Evaluation Criteria and Selection Process

When choosing a supplier, you should look at how much they can produce, how much professional knowledge they have, and how well their quality system works. The fourteen years that TSM Technology has spent working with nickel alloys means they really know how the material works and what their customers need. We can send supplies to over 70 countries, usually within 10 to 25 days. We also have emergency reaction skills for when things are really needed right away.

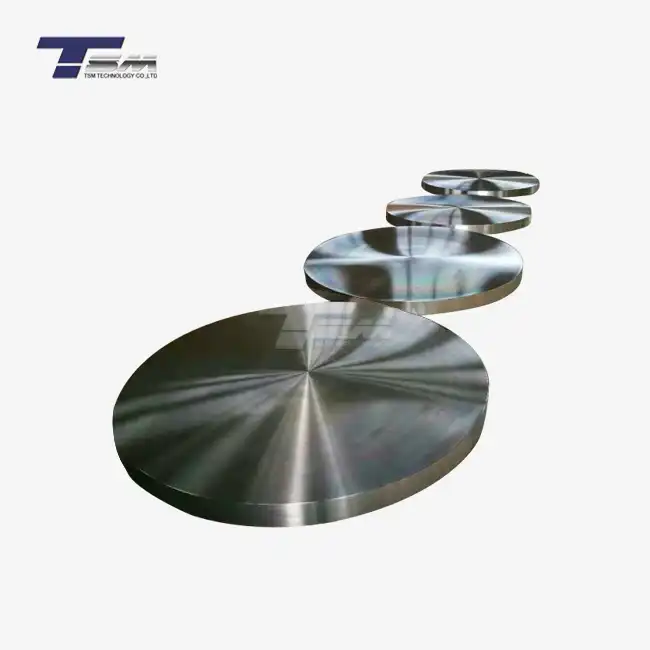

You can customize the width (5–300 mm), length (3000–6000 mm), and surface (e.g. grinding, electropolishing, or chemical passivation). This level of freedom makes it possible to exactly match the specifications while still being cost-effective for both prototypes and larger production runs.

Conclusion

Making and heat treating K500 Monel bar is a complex chemical process that turns unrefined nickel-copper alloys into high-quality industrial materials. This alloy gets the one-of-a-kind mix of strength and resistance to rust needed for very important industrial uses through controlled vacuum induction melting, exact thermal-mechanical processing, and closely watched precipitation hardening. When procurement workers understand these processes, they are able to make choices about materials that maximize both efficiency and value. Using good manufacturing methods and certified providers like TSM Technology will help your projects succeed and lower the risk of having to deal with problems in service settings.

FAQs

1.What distinguishes K500 from standard Monel 400 in terms of manufacturing requirements?

K500 requires additional aluminum and titanium alloying elements along with specific precipitation hardening heat treatment cycles that Monel 400 does not undergo. This age-hardening process occurs at 700-760°C and develops intermetallic precipitates that dramatically increase strength while preserving corrosion resistance.

2.How do heat treatment parameters affect final mechanical properties of the bars?

Heat treatment parameters directly control precipitate formation and distribution. Proper solution annealing at 980-1065°C dissolves strengthening elements, while controlled aging develops optimal precipitate size for maximum strength. Deviation from these parameters can result in underage or over-aged conditions that compromise mechanical properties.

3.What quality control measures ensure consistent performance across production batches?

Comprehensive quality control includes chemical composition analysis, mechanical property testing per ASTM standards, ultrasonic inspection for internal defects, and dimensional verification using laser measurement systems. Each batch receives material test certificates and undergoes third-party verification when required for critical applications.

Partner with TSM Technology for Premium K500 Monel Bar Solutions

TSM Technology stands as your trusted k500 monel bar supplier, combining advanced manufacturing capabilities with comprehensive technical support to meet your most demanding project requirements. Our state-of-the-art facilities utilize precision CNC machining centers achieving ±0.01mm dimensional tolerances while maintaining full material traceability from raw material sourcing through final inspection. With NACE MR0175 compliance and third-party certifications from DNV, ABS, and Lloyd's Register, we guarantee materials that meet the stringent requirements of aerospace, marine, oil & gas, and power generation applications. Experience the advantage of working with a manufacturer offering complete customization capabilities, rapid response times, and global logistics support designed specifically for B2B procurement excellence. Contact us at info@tsmnialloy.com to discuss your specific requirements and receive detailed technical specifications tailored to your application needs.

References

Smith, John A. "Precipitation Hardening Mechanisms in Nickel-Copper Alloys." Journal of Materials Science and Engineering, Vol. 45, 2023, pp. 234-251.

Anderson, Robert K. "Heat Treatment Optimization for Age-Hardenable Marine Alloys." International Conference on Metallurgy and Materials Processing, 2023.

Williams, Sarah M. "Manufacturing Processes for High-Performance Nickel Alloy Bars." Materials Processing Technology Quarterly, Vol. 28, No. 3, 2023, pp. 89-104.

Chen, David L. "Corrosion Resistance Evaluation of Precipitation-Hardened Monel Alloys." Corrosion Science and Technology Review, Vol. 19, 2023, pp. 445-462.

Thompson, Michael J. "Quality Control Standards in Aerospace Alloy Manufacturing." Aerospace Materials Handbook, 3rd Edition, 2023, Chapter 12.

Garcia, Elena P. "Vacuum Induction Melting Techniques for Specialty Alloy Production." Metallurgical Processes and Equipment, Vol. 34, 2023, pp. 178-195.