Understanding Nickel Alloy Tube Compositions and Their Impact

Elemental Composition of Nickel Alloy Tubes

Nickel alloy tubes are engineered with precise elemental compositions to achieve specific properties. The primary alloying elements, such as chromium, molybdenum, and tungsten, contribute to enhanced corrosion resistance and mechanical strength. For instance, increasing the chromium content improves resistance to oxidation at high temperatures, while molybdenum enhances pitting resistance in chloride environments. The careful balance of these elements determines the tube's performance characteristics and influences its cost.

Effect of Alloying Elements on Performance

Each alloying element in nickel alloy pipes serves a unique purpose. Nickel, as the base metal, provides excellent resistance to reducing environments and alkalis. Chromium forms a protective oxide layer, enhancing resistance to oxidizing media. Molybdenum and tungsten improve resistance to pitting and crevice corrosion. The synergistic effects of these elements result in superior performance in harsh environments, such as those found in chemical processing plants or offshore oil rigs.

Cost Implications of Alloy Compositions

The cost of nickel alloy tubes is directly related to their composition. Alloys with higher percentages of expensive elements like nickel, molybdenum, and cobalt command premium prices. For example, Hastelloy alloys, known for their exceptional corrosion resistance, are more expensive due to their complex compositions. Conversely, alloys with lower nickel content and fewer exotic elements are more budget-friendly but may offer reduced performance in extreme conditions.

Performance Characteristics of Different Nickel Alloy Tube Grades

Corrosion Resistance Across Grades

Nickel alloy tubes exhibit varying degrees of corrosion resistance depending on their grade. High-performance grades like Inconel 625 offer outstanding resistance to a wide range of corrosive media, including seawater and acidic environments. This exceptional resistance translates to longer equipment lifespans and reduced maintenance costs. Lower-grade alloys may suffice in less aggressive environments but could require more frequent replacement in harsher conditions, affecting long-term operational costs.

Mechanical Properties and Temperature Resistance

The mechanical strength and temperature resistance of nickel alloy tubes vary significantly across grades. Some alloys maintain their strength at extremely high temperatures, making them ideal for applications in aerospace and power generation. For instance, Inconel 718 retains its mechanical properties up to 1300°F (704°C), justifying its higher cost in critical high-temperature applications. Lower-grade alloys may offer adequate performance at moderate temperatures but could fail prematurely in more demanding scenarios.

Weldability and Fabrication Considerations

The ease of welding and fabrication differs among nickel alloy tube grades, impacting both performance and cost. Some high-performance alloys require specialized welding techniques and equipment, increasing fabrication costs. However, their superior weld integrity can lead to better long-term performance and reduced maintenance expenses. More easily weldable grades may offer cost savings during initial fabrication but might not provide the same level of joint strength or corrosion resistance in critical applications.

Cost-Benefit Analysis of Nickel Alloy Tube Selection

Initial Investment vs. Long-Term Value

When selecting nickel alloy tubes, it's crucial to balance the initial investment against long-term value. Higher-grade alloys often come with a steeper upfront cost but can offer significant savings over time through extended service life and reduced maintenance requirements. For instance, using a more corrosion-resistant grade in a chemical processing plant may prevent costly shutdowns and extend equipment lifespan, ultimately providing a better return on investment despite the higher initial expense.

Application-Specific Performance Requirements

Matching the nickel alloy tube grade to specific application requirements is essential for optimizing both performance and cost. Over-specifying can lead to unnecessary expenses, while under-specifying risks premature failure and increased long-term costs. For example, in less demanding environments, a mid-range nickel alloy pipe might offer the ideal balance of performance and cost-effectiveness. Careful analysis of operating conditions, including temperature, pressure, and chemical exposure, is crucial for selecting the most appropriate and cost-efficient grade.

Lifecycle Cost Considerations

The total lifecycle cost of nickel alloy tubes extends beyond the initial purchase price. Factors such as installation complexity, maintenance requirements, and end-of-life disposal or recycling all contribute to the overall cost. Higher-grade alloys may offer advantages in terms of easier maintenance and higher scrap value, potentially offsetting their higher initial cost. Conversely, lower-grade options might require more frequent replacement or additional protective measures, increasing long-term expenses. A comprehensive lifecycle analysis helps in making informed decisions that balance performance needs with budget constraints.

Conclusion

The selection of nickel alloy tube grades significantly impacts both performance and cost in industrial applications. Higher-grade alloys offer superior corrosion resistance, mechanical properties, and temperature tolerance, often justifying their premium price through extended service life and reduced maintenance. However, careful consideration of specific application requirements is essential to avoid over-specification and unnecessary expenses. By conducting a thorough cost-benefit analysis that includes initial investment, long-term value, and lifecycle costs, industries can optimize their choice of nickel alloy tubes, ensuring optimal performance while managing costs effectively.

FAQs

What are the most common nickel alloy tube grades?

Common grades include Inconel 600, 625, and 718, Monel 400, and Hastelloy C-276.

How do I choose the right nickel alloy tube for my application?

Consider factors like operating temperature, corrosive environment, mechanical stress, and budget constraints.

Are higher-grade nickel alloy tubes always necessary?

Not always. The choice depends on specific application requirements and cost considerations.

Can nickel alloy tubes be recycled?

Yes, most nickel alloy tubes are recyclable, which can offset their initial cost.

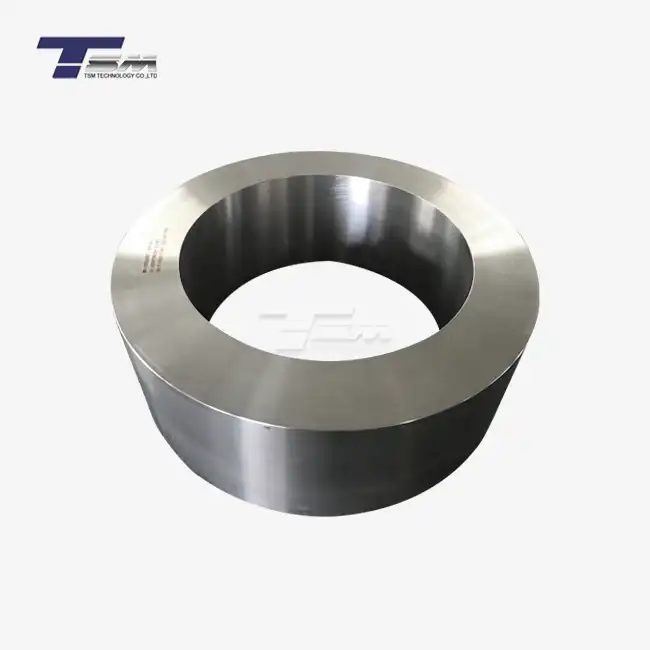

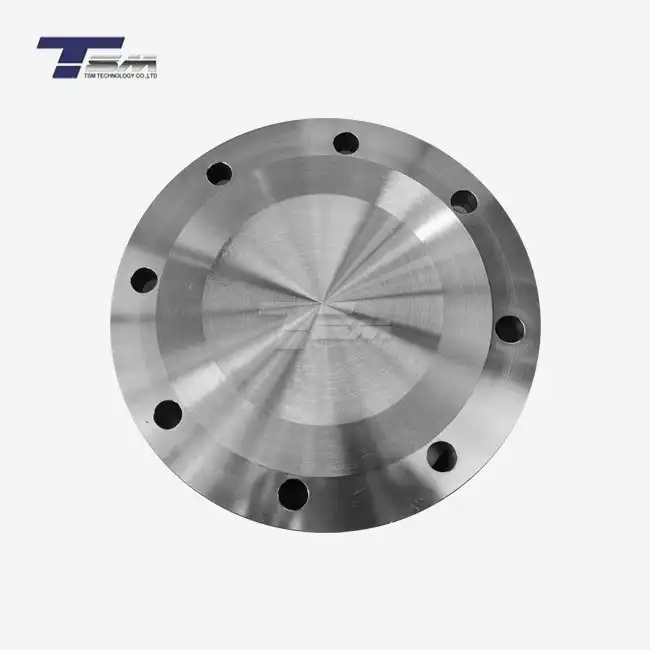

Expert Nickel Alloy Tube Solutions for Optimal Performance and Cost-Efficiency | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing superior nickel alloy tubes tailored to your specific needs. Our extensive range of high-quality alloys, including Monel, Inconel, and Hastelloy, ensures optimal performance across various industrial applications. As a leading Nickel alloy tube manufacturer and supplier, we offer expert guidance in selecting the most cost-effective solutions without compromising on quality. Contact our team at info@tsmnialloy.com to discover how our premium nickel alloy products can enhance your project's efficiency and longevity.

References

Smith, J.R. (2021). "Nickel Alloy Tube Performance in Extreme Environments." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. & Lee, C.D. (2020). "Cost-Benefit Analysis of High-Performance Nickel Alloys in Industrial Applications." Corrosion Science, 162, 108719.

Martinez, S.L. et al. (2019). "Comparative Study of Nickel Alloy Tube Grades for Chemical Processing Industries." Materials & Design, 178, 107860.

Wong, K.H. (2022). "Lifecycle Assessment of Nickel Alloy Tubing in Aerospace Applications." Journal of Aerospace Engineering, 35(2), 04021132.

Patel, R.V. & Garcia, M.E. (2018). "Optimizing Nickel Alloy Selection for Cost-Effective Corrosion Resistance." Materials Performance, 57(9), 32-38.

Yamamoto, T. et al. (2023). "Advanced Nickel Alloy Tubes: Balancing Performance and Economic Considerations." Metallurgical and Materials Transactions A, 54(4), 1234-1248.