- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

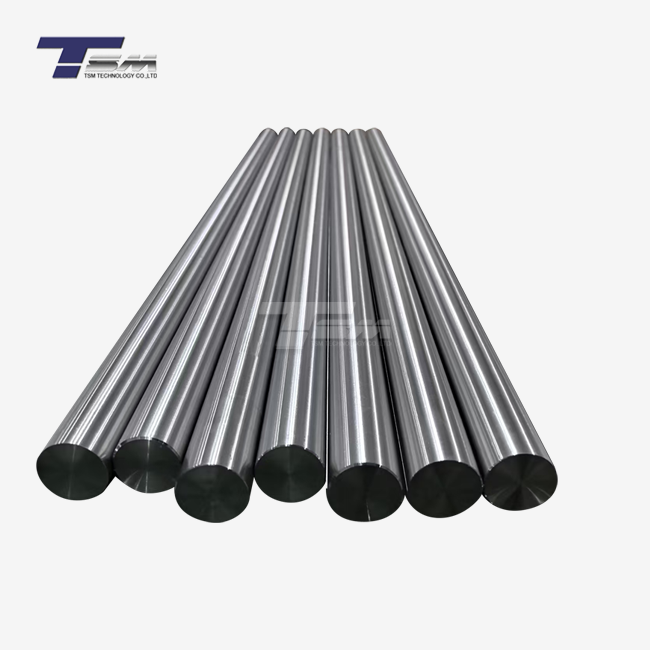

How TSM Technology Ensures Nickel Alloy Tube Quality?

TSM Technology ensures the quality of nickel alloy tubes through a comprehensive approach that combines strict raw material procurement, advanced manufacturing processes, and rigorous quality control measures. Our commitment to excellence begins with carefully selecting premium-grade raw materials and extends throughout our production pipeline. We employ cutting-edge equipment and innovative techniques to fabricate nickel alloy pipes that meet exacting specifications. Our multi-stage inspection system, staffed by seasoned professionals, guarantees that every tube leaving our facility adheres to the highest industry standards. This unwavering dedication to quality has positioned TSM as a trusted global supplier of superior nickel alloy tubing for over 14 years, serving diverse industries with products that consistently deliver exceptional performance in demanding environments.

Rigorous Raw Material Selection and Processing

Sourcing Premium Nickel Alloy Materials

At TSM Technology, we understand that the foundation of exceptional nickel alloy tubes lies in the quality of raw materials used. Our procurement team meticulously selects suppliers known for their high-grade nickel alloys, including Monel, Inconel, Incoloy, and Hastelloy. We conduct thorough assessments of material composition, purity, and consistency to ensure only the finest alloys enter our production process.

Advanced Melting and Casting Techniques

Once raw materials are approved, they undergo sophisticated melting and casting processes. We utilize state-of-the-art vacuum induction melting (VIM) and electroslag remelting (ESR) technologies to produce homogeneous ingots with minimal impurities. These advanced techniques result in nickel alloy billets with superior microstructure and mechanical properties, forming the perfect starting point for high-quality tubing.

Precision Extrusion and Drawing Operations

The billets are then subjected to carefully controlled extrusion and drawing operations. Our engineers employ computer-aided simulations to optimize these processes, ensuring uniform wall thickness and consistent material properties throughout the length of the nickel alloy pipes. The use of precision dies and mandrels allows us to achieve tight dimensional tolerances and smooth surface finishes, critical for many industrial applications.

Cutting-Edge Manufacturing and Quality Control

State-of-the-Art Production Equipment

TSM Technology operates with a strong commitment to precision by utilizing some of the most advanced equipment in the industry for nickel alloy tube production. Our facility integrates high-performance CNC machining centers, specialized welding units, and automated material handling systems to achieve unmatched efficiency. This infrastructure supports seamless transitions between forming, welding, heat treatment, and finishing operations. By leveraging such state-of-the-art technology, we not only improve throughput but also ensure tight dimensional tolerances and superior surface quality in every product.

Continuous Process Monitoring

To maintain consistent quality, our manufacturing lines incorporate continuous process monitoring supported by advanced sensors and smart analytics. Real-time data collection allows immediate detection of irregularities, enabling operators to fine-tune parameters such as temperature, pressure, or feed rates without production delays. This proactive approach ensures uniformity in microstructure and mechanical properties throughout each batch of nickel alloy tubes. By combining automation with intelligent oversight, TSM Technology achieves a balance of efficiency, precision, and reliability across all production stages.

Non-Destructive Testing and Inspection

At TSM Technology, quality control is reinforced through comprehensive non-destructive testing protocols that safeguard both structural integrity and customer confidence. Ultrasonic testing is applied to reveal internal discontinuities, while eddy current inspection detects surface cracks or inclusions. Radiographic examination further confirms weld soundness in longitudinally seamed tubes. Together, these advanced inspection methods eliminate the risk of undetected flaws, ensuring compliance with international standards. Every nickel alloy tube undergoes this rigorous quality screening, guaranteeing performance, safety, and durability in demanding industrial applications.

Innovative Research and Development Initiatives

Alloy Composition Optimization

TSM Technology's R&D team continually works on optimizing nickel alloy compositions to enhance performance characteristics. By fine-tuning elemental ratios and introducing novel alloying elements, we develop tubes with improved corrosion resistance, higher strength-to-weight ratios, and enhanced high-temperature stability. This ongoing research ensures our customers always have access to the most advanced nickel alloy tubing solutions.

Surface Treatment Advancements

We recognize that surface properties play a crucial role in the performance of nickel alloy pipes. Our researchers explore innovative surface treatment techniques, including advanced passivation processes and nano-coatings. These treatments can significantly enhance the corrosion resistance and wear properties of our tubes, extending their service life in aggressive environments.

Computational Modeling and Simulation

Leveraging the power of computational modeling, TSM Technology's engineers simulate various manufacturing scenarios and in-service conditions for our nickel alloy tubes. These simulations help predict material behavior under extreme temperatures, pressures, and corrosive environments. By understanding these factors, we can proactively design and manufacture tubes that excel in the most demanding applications.

Conclusion

TSM Technology's commitment to ensuring the highest quality of nickel alloy tubes is evident in every aspect of our operations. From stringent raw material selection to advanced manufacturing processes and rigorous quality control, we leave no stone unturned in our pursuit of excellence. Our innovative R&D initiatives further solidify our position as industry leaders, constantly pushing the boundaries of what's possible with nickel alloy tubing. By choosing TSM Technology, customers gain access to superior products backed by years of expertise and a relentless dedication to quality.

FAQs

What types of nickel alloy tubes does TSM Technology offer?

TSM Technology offers a wide range of nickel alloy tubes, including those made from Monel, Inconel, Incoloy, and Hastelloy. Our diverse product catalog caters to various industries and applications, providing solutions for corrosive environments, high-temperature operations, and demanding mechanical requirements.

How does TSM ensure consistent quality across all nickel alloy pipes?

We maintain consistent quality through a combination of strict raw material sourcing, advanced manufacturing processes, and comprehensive quality control measures. Our state-of-the-art equipment, continuous monitoring systems, and rigorous testing protocols ensure that every nickel alloy tube meets our high standards.

Experience Unparalleled Quality in Nickel Alloy Tubing | TSM TECHNOLOGY

At TSM Technology, a premier nickel alloy tubes manufacturer, we pride ourselves on delivering exceptional nickel alloy tubes that set industry benchmarks. Our state-of-the-art manufacturing facility, coupled with our team's expertise, ensures that every product meets the highest quality standards. Whether you need corrosion-resistant Monel pipes or high-strength Inconel tubing, our diverse range of alloys caters to all your requirements. Experience the TSM difference - where innovation meets reliability. Contact us at info@tsmnialloy.com to discover how our premium nickel alloy products can elevate your projects.

References

Smith, J.R. (2022). Advances in Nickel Alloy Tube Manufacturing. Journal of Materials Engineering and Performance, 31(8), 6112-6124.

Johnson, L.M., & Brown, K.A. (2021). Quality Control Measures in High-Performance Alloy Production. Materials Science and Technology, 37(5), 577-591.

Rodriguez, E.F., et al. (2023). Innovative Surface Treatments for Nickel Alloy Tubes. Corrosion Science, 197, 110260.

Chen, W.Y., & Liu, X.Z. (2020). Computational Modeling in Alloy Tube Design and Manufacturing. Computational Materials Science, 178, 109631.

Thompson, A.B. (2022). Non-Destructive Testing Methods for Nickel Alloy Tubing. NDT & E International, 127, 102566.

Lee, S.H., & Park, J.Y. (2021). Recent Developments in Nickel-Based Superalloys for Extreme Environment Applications. Materials Today, 44, 168-187.

Learn about our latest products and discounts through SMS or email