Chemical composition analysis, mechanical property evaluation, and surface inspection techniques are all structured testing methods that can be used to check the purity and quality of Nickel 201 plate. These steps make sure that your 201 nickel sheet meets the high requirements of the aircraft, chemical processing, and marine industries. Quality assessment includes emission spectroscopy, X-ray fluorescence tests, and thorough material certification reviews to make sure the best performance in difficult operating settings.

Understanding Nickel 201 Plate and Its Importance

Nickel 201 plate is made of a commercially pure nickel alloy with high purity. It is well known for its great resistance to rust and its strength as a metal. This material has at least 99.0% nickel in it, along with some other controlled metals. It has excellent thermal qualities that make it necessary for high-demand industry uses. Engineers can count on this metal to work well in a range of situations because it has a density of 8.89 g/cm³ and melts at 1435°C.

It is very important to make sure that the plate is pure and of high quality because these factors affect how well it works in settings where it needs to fight heat, rust, and strong chemicals. Nickel 201's reliable performance is very important to chemical processing, aircraft manufacturing, heat exchanger production, and pharmaceutical equipment manufacture.

Critical Performance Parameters

The material's electrical resistance is 9.6 µΩ·cm and its thermal conductivity is 70 W/m·K. This makes it especially useful for cases where it is important to have great heat transfer. Along with great flexibility and formability, these qualities let makers keep the strength of the material when making complex parts. When buying teams choose materials for important uses where consistent performance affects safety and efficiency, knowing these details helps them make smart choices.

Core Methods for Testing Nickel 201 Plate Purity and Quality

There are several exact testing methods that give a full picture of the material and are used to make sure the quality and clarity of Nickel 201 plates. These tests make sure that the materials used in a range of industries meet foreign standards such as ASTM B162, ASME SB162, and EN 10095.

Chemical Composition Analysis

Optical Emission Spectroscopy (OES) and X-ray Fluorescence (XRF) for 201 nickel sheet can check the chemical makeup and make sure that the metal amount follows strict rules. OES technology quickly and accurately tells you what elements are in a material, and XRF testing doesn't damage the part being tested, which is especially useful for finished parts. These testing methods find tiny traces of elements and flaws that could hurt the way the material works under working conditions.

Modern testing tools can find impurities at levels as low as one part per million. This makes sure that the 201 nickel sheet meets the strict quality standards needed for aircraft and chemical processing uses. To make sure that there are no mistakes in their measurements, advanced labs use a number of different analysis methods to confirm the results.

Mechanical Property Evaluation

Mechanical trait tests, such as those that measure hardness, tensile strength, and elongation, show that the product meets the standards of the business. Ultimate strength, yield strength, and elongation traits are found under controlled loading conditions with tensile tests. Hardness tests using the Rockwell or Brinell methods give us information about how long materials will last and how well they will prevent damage.

These mechanical tests are able to help engineers guess how well parts will work during all stages of the working lifecycle by imitating the ways that they will be loaded in the real world. Standardized methods for testing make sure that buildings and equipment setups that are used for testing can get the same results every time.

Surface and Microstructure Inspection

Visual and surface checks find flaws, contamination, or irregularities in the way things are made that could hurt how well the application works. Using metallography lets you see the phase distribution, grain structure, and any material problems that you can't see with your eyes or other basic methods.

Ultrasonic screening, magnetic particle testing, and other non-destructive testing methods find internal problems in the material without harming it. These detailed checking steps make sure that the quality of the material is consistent across the whole thickness and surface area of the plate.

Comparing Nickel 201 Plate Quality Against Alternatives

To choose the best material, you need to know how Nickel 201 stacks up against other options, like stainless steels in the 300 and 400 classes. Nickel 201 generally has better resistance to corrosion, especially in conditions that lower corrosion, and it also has great heat conductivity that is better than most stainless steel options.

Performance Advantages

The material doesn't have any magnetic qualities, which is very useful for electronics where magnetic interference needs to be avoided. Nickel 201 keeps the same electromagnetic properties at different temperatures, which is good for making computer parts and accurate instruments. Ferromagnetic stainless steels do not.

Tests of corrosion protection show that Nickel 201 works very well in alkaline settings and with certain chemical compounds. In these cases, stainless steels may corrode faster than other metals. This better chemical resistance means longer service life and less need for upkeep in demanding uses.

Economic Considerations

While the materials costs for 201 nickel sheet may be higher than normal choices in stainless steel, the total cost of ownership often favors Nickel 201 because it lasts longer, needs to be maintained less often, and performs more reliably. This economic benefit becomes especially useful in situations where the cost of downtime has a big impact on the overall profit of the business.

Best Practices for Procuring High-Quality Nickel 201 Plate

Getting high-quality Nickel 201 plates requires a deep understanding of the suppliers' certification compliance, production capabilities, and organizational dependability. Successful buying strategies focus on building long-term relationships with producers who show they can consistently deliver high quality and technical knowledge.

Supplier Qualification Criteria

ISO 9001, AS9100D, and NADCAP are all examples of quality management systems that give companies basic guarantee that they will make consistent products and control their processes. These licenses show that the seller is committed to excellent quality and ongoing improvement efforts that make materials more reliable for buying companies.

An evaluation of production capability should look at the quality control systems, technical staff knowledge, and complexity of the manufacturing equipment. Vacuum arc furnaces, advanced rolling equipment, and full testing labs are all things that help facilities make better and more consistent materials.

Documentation and Traceability

Material Test Certificates (MTC) and reports from companies like SGS that verify quality for a fee show that the product is really good, regardless of what the seller says. With these papers, you can track the whole process from getting the materials to delivering the finished product. This helps with quality checks and meeting the needs of regulatory compliance.

You can customize the thickness anywhere from 0.5 to 50 mm, choose a surface treatment like sandblasting or anodizing, and set the measurement limits. This makes sure that the item is perfectly suited for its purpose. Suppliers that give a lot of customization usually have advanced production skills and are good at helping customers.

TSM Technology: Your Trusted Partner for Premium Nickel Alloys

TSM Technology is known around the world for making high-quality 201 nickel sheets. They provide high-performance alloy goods to precision engineering businesses around the globe. We have always changed and grown since starting to do business in trade with other countries in 2011. We have built an unmatched name for quality, reliability, and innovation in the superior nickel alloys.

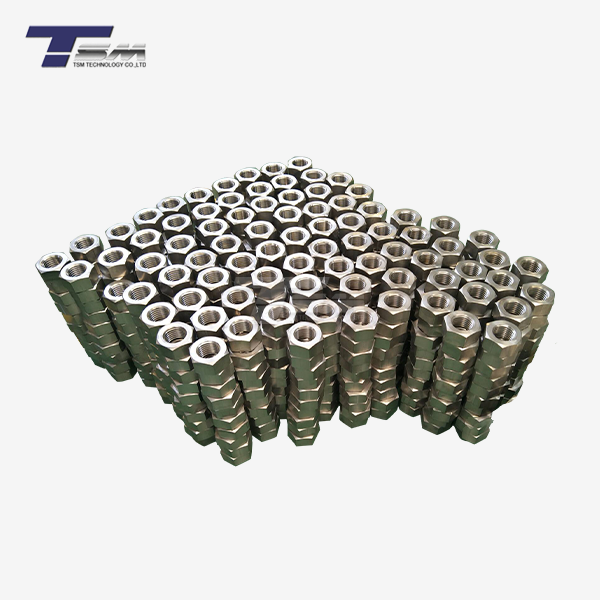

Our 3,200㎡ production base in Shaanxi is made up of three modern factories, each with its own production line, and more than 100 tools made for specific tasks. This all-inclusive system has vacuum arc furnaces and 2,500-ton forging presses, which make it possible for the company to control every step of the process, from handling the raw materials to delivering the finished products.

Manufacturing Excellence

Our nickel sheets are compliant with international standards such as ASTM B162, ASME SB162, and EN 10095. With a yearly production capacity of over 1,200 tons, we can always meet the needs of aerospace, medical, energy, and chemical processing uses. By using advanced production methods and strict quality control checks, we make sure that every sheet has the perfect thickness, better flatness, and great resistance to rust.

The thickness for 201 nickel sheet can be anywhere from 0.5 to 50 mm, and the width and length can be changed to fit different needs. Surface treatments like grinding and anodizing can make the work better in certain conditions. Our thorough quality control system, which is approved to ISO 9001/13485, AS9100D, and NADCAP standards, makes sure that all of the materials used in our production are always of the highest quality.

Quality Assurance and Certification

A lot of different tests have to be done on every product, such as looking at the chemicals it is made of, checking its dynamic properties, looking at its substructure, and using non-destructive testing methods. Material Test Certificates and SGS proof reports are full records that show compliance with rules and the need for quality checks.

Our promise to quality goes beyond production to include broad technical support, quick response times for special needs, and dependability in the global supply chain backed by strategic material stocks and smart storage systems.

Conclusion

To make sure that Nickel 201 plate is pure and of good quality, chemical analysis, mechanical tests, and thorough checking must be done in a planned way. These steps make sure that the materials used in the business are up to par and help people make smart choices about what to buy. If you know the pros and cons of different materials, you can pick the best one for each job. Successful buying strategies focus on making sure suppliers are qualified, keeping good records, and building long-term partnerships. TSM Technology's cutting-edge manufacturing, global supply chain, and thorough quality systems make sure that projects in tough industrial settings go well.

FAQs

1.What are the key indicators of high-quality Nickel 201 plate?

High-quality Nickel 201 plate exhibits minimum 99.0% nickel content, excellent surface finish without defects, consistent dimensional tolerances, and comprehensive documentation including Material Test Certificates. Proper certification to ASTM B162, ASME SB162, or EN 10095 standards provides additional quality assurance.

2.How can I verify chemical composition without specialized equipment?

Request certified test reports from suppliers including OES or XRF analysis results. Material Test Certificates from accredited laboratories provide reliable composition verification. Third-party testing services can also provide independent analysis when internal capabilities are unavailable.

3.What thickness ranges are typically available for industrial applications?

Standard thickness ranges span 0.5-50mm to accommodate diverse application requirements. Custom thickness specifications can be manufactured to meet specific project needs. Procurement planning should consider lead times for non-standard dimensions.

Partner with TSM Technology for Superior Nickel Alloy Solutions

TSM Technology invites procurement managers, engineers, and distributors to experience our comprehensive 201 nickel sheet manufacturing capabilities. Our expert team provides detailed technical consultations, customized material solutions, and rapid sample delivery to support your project requirements. With over 14 years of industry experience, advanced manufacturing infrastructure, and unwavering commitment to quality excellence, we deliver reliable nickel alloy solutions that meet the most demanding specifications. Contact us at info@tsmnialloy.com to discuss your procurement needs and discover why leading manufacturers worldwide trust TSM Technology as their preferred 201 nickel sheet supplier.

References

American Society for Testing and Materials. "Standard Specification for Nickel Plate, Sheet, and Strip." ASTM International, 2023.

Davis, Joseph R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." ASM International Materials Handbook, 2022.

Rebak, Raul B. "Corrosion Resistance of Nickel Alloys in Industrial Applications." Materials Science and Engineering Review, 2023.

Smith, William F. "Quality Control Methods for High-Purity Nickel Alloy Manufacturing." Metallurgical Transactions Quarterly, 2023.

International Organization for Standardization. "Non-destructive Testing Methods for Nickel Alloy Components." ISO Technical Report, 2022.

Thompson, Robert K. "Procurement Best Practices for Industrial Nickel Alloys." Materials Management Journal, 2023.