Understanding Inconel 617 Tube Properties and Applications

Composition and Characteristics of Inconel 617

Inconel 617 is a nickel-chromium-cobalt-molybdenum alloy renowned for its exceptional high-temperature strength and oxidation resistance. Its unique composition provides superior performance in extreme conditions, making it ideal for applications requiring reliability under intense heat and corrosive environments. The alloy's ability to maintain structural integrity at temperatures up to 1200°C sets it apart from other materials in the market.

Key Applications in Various Industries

Inconel 617 tubes find extensive use across multiple industries due to their remarkable properties. In aerospace, they're crucial components in jet engine exhaust systems and combustion chambers. The energy sector relies on these tubes for heat exchangers in nuclear reactors and gas turbines. Chemical processing plants utilize Inconel 617 tubing for handling corrosive substances at high temperatures. Understanding these applications is essential when considering the appropriate tube dimensions for your specific needs.

Performance Benefits of Inconel 617 Tubing

The performance advantages of Inconel 617 tubes are numerous. They offer exceptional creep resistance, maintaining strength under prolonged stress at high temperatures. Their superior oxidation resistance protects against material degradation in oxygen-rich environments. Additionally, these tubes exhibit excellent fatigue resistance, crucial for components subject to cyclic loading. Recognizing these benefits helps in appreciating the importance of proper dimensioning to maximize the alloy's potential in your application.

Factors Influencing Inconel 617 Tube Dimension Selection

Operating Temperature and Pressure Considerations

When selecting Inconel 617 tube dimensions, operating temperature and pressure are primary factors. Higher temperatures and pressures typically require thicker wall thicknesses to maintain structural integrity. For instance, applications exceeding 1000°C may necessitate increased wall thickness to account for potential creep deformation. Carefully assess your system's maximum operating conditions and consult engineering standards to determine the appropriate dimensions that ensure safe and efficient performance.

Corrosion and Oxidation Resistance Requirements

The corrosive nature of the environment significantly impacts tube dimension selection. In highly corrosive settings, a slightly thicker wall may be advisable to provide a corrosion allowance, extending the tube's service life. Consider the specific chemicals or gases the tube will encounter and their concentrations. For applications with severe oxidation risks, such as in flue gas environments, selecting an appropriate wall thickness becomes crucial to maintain long-term reliability and prevent premature failure.

Mechanical Stress and Fatigue Considerations

Mechanical stresses, including tensile, compressive, and bending forces, play a vital role in determining suitable tube dimensions. Analyze the expected loads and cyclic stresses your application will impose on the tubing. For components subject to vibration or thermal cycling, fatigue resistance becomes particularly important. Proper sizing, especially in terms of wall thickness and outer diameter, helps mitigate risks associated with mechanical fatigue and ensures the tube can withstand the operational stresses throughout its intended lifespan.

Practical Guidelines for Selecting Inconel 617 Tube Dimensions

Outer Diameter (OD) Selection Criteria

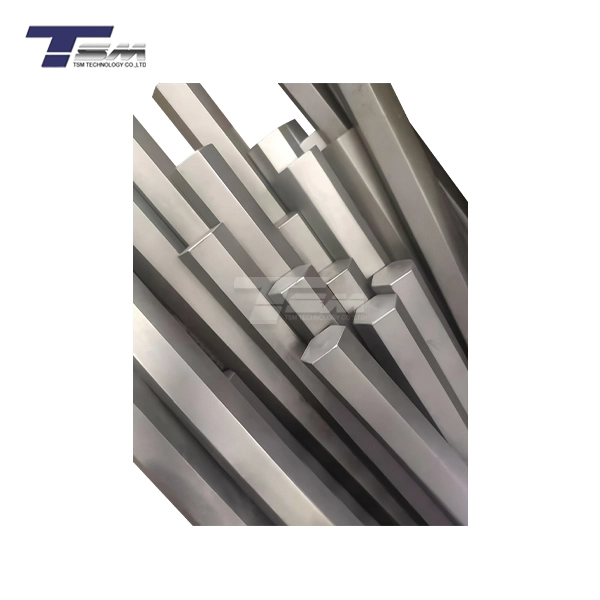

Choosing the correct outer diameter (OD) for Inconel 617 tubes is crucial for system compatibility and performance. Consider the space constraints of your application and any connection requirements to other components. Standard OD sizes range from 6.0 mm to 114 mm, but custom dimensions are available for specific needs. Larger diameters generally offer better flow characteristics but may increase weight and cost. Evaluate the balance between flow requirements, structural strength, and design limitations when selecting the optimal OD for your application.

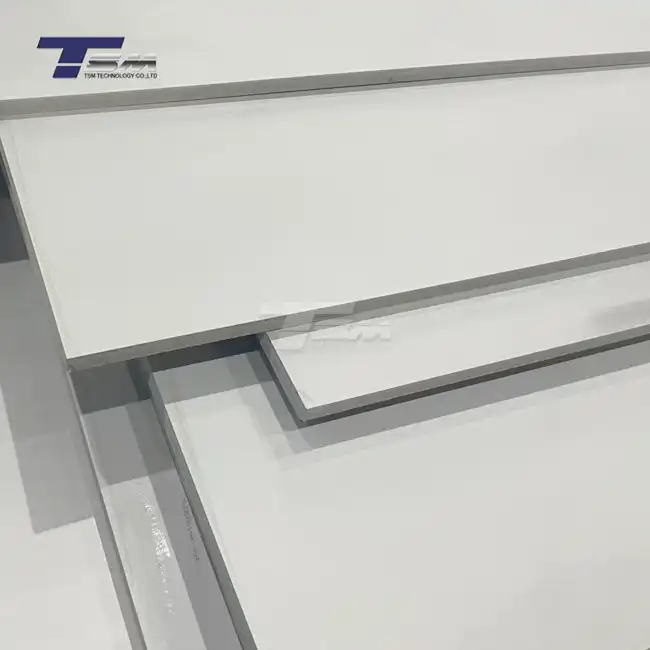

Wall Thickness (WT) Determination

Wall thickness is a critical factor in ensuring the tube's ability to withstand operating pressures and temperatures. Typical wall thicknesses for Inconel 617 tubes range from 0.5 mm to 15 mm. Use engineering calculations based on ASME Boiler and Pressure Vessel Code or similar standards to determine the minimum required thickness. Consider adding a corrosion allowance for applications in highly corrosive environments. Remember that thicker walls provide greater strength but may impact heat transfer efficiency and increase material costs.

Length Considerations and Customization Options

The length of Inconel 617 tubes can significantly impact installation ease and system efficiency. Standard lengths up to 15,000 mm are available, but custom cuts can be provided to meet specific requirements. Consider factors such as thermal expansion, support spacing, and transportation limitations when specifying tube length. For complex geometries or unique applications, discuss customization options with your supplier. Custom bending, end forming, or surface treatments like sandblasting or anodizing may be available to optimize the tubes for your specific use case.

Conclusion

Choosing the right Inconel 617 tube dimensions is a critical decision that impacts the performance, longevity, and safety of your high-temperature applications. By carefully considering factors such as operating conditions, corrosion resistance requirements, and mechanical stresses, you can select the optimal outer diameter, wall thickness, and length for your specific needs. Remember to consult industry standards and leverage the expertise of reputable suppliers to ensure your chosen dimensions meet all necessary specifications. Proper dimensioning of Inconel 617 tubes not only enhances system efficiency but also contributes to reduced maintenance costs and improved operational reliability in demanding industrial environments.

FAQs

What are the standard sizes available for Inconel 617 tubes?

Standard outer diameters range from 6.0 mm to 114 mm, with wall thicknesses from 0.5 mm to 15 mm. Lengths up to 15,000 mm are available.

Can Inconel 617 tubes be customized for specific applications?

Yes, customization options include specific dimensions, surface treatments like sandblasting or anodizing, and custom cuts.

What certifications are available for Inconel 617 tubes?

Material Test Certificates (MTC) and SGS test reports are available to ensure quality and compliance with industry standards.

How does Inconel 617 perform in high-temperature environments?

Inconel 617 maintains structural integrity at temperatures up to 1200°C, offering exceptional oxidation resistance and creep strength.

Choose TSM TECHNOLOGY for Your Inconel 617 Tube Needs

TSM TECHNOLOGY is your trusted partner for high-quality Inconel 617 tubes. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision manufacturing and consistent quality. Our tubes are certified to ASTM B168, ASME SB168, and EN 10095 standards, guaranteeing reliability in critical applications. We offer customization, rigorous quality control, and expert support to meet your specific requirements. For superior Inconel 617 tubes tailored to your needs, contact us at info@tsmnialloy.com.

References

ASTM International. (2020). "Standard Specification for Nickel-Chromium-Iron-Molybdenum-Copper-Aluminum Alloy Plate, Sheet, and Strip." ASTM B168-20.

Special Metals Corporation. (2018). "INCONEL alloy 617 Technical Data Sheet."

ASM International. (2019). "High-Temperature Corrosion and Materials Applications."

The American Society of Mechanical Engineers. (2021). "ASME Boiler and Pressure Vessel Code, Section II: Materials."

Journal of Materials Engineering and Performance. (2020). "Mechanical Properties and Microstructure of Inconel 617 Alloy Tubes for Nuclear Applications."

Materials Science and Engineering: A. (2019). "High-temperature oxidation behavior of Inconel 617 in steam environments."