- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Typical Processing Steps for Monel 404 Tube?

The typical processing steps for Monel 404 tube include material preparation, tube forming, heat treatment, surface finishing, and quality control. This nickel-copper alloy undergoes careful manufacturing to ensure its exceptional corrosion resistance and mechanical properties. The process begins with raw material selection and melting, followed by hot working to create the initial tube shape. Subsequent cold working, annealing, and precision machining refine the tube's dimensions and properties. Finally, rigorous testing and inspection ensure the finished Monel 404 tube meets strict industry standards for performance in demanding marine, chemical, and industrial applications.

Raw Material Preparation and Initial Forming

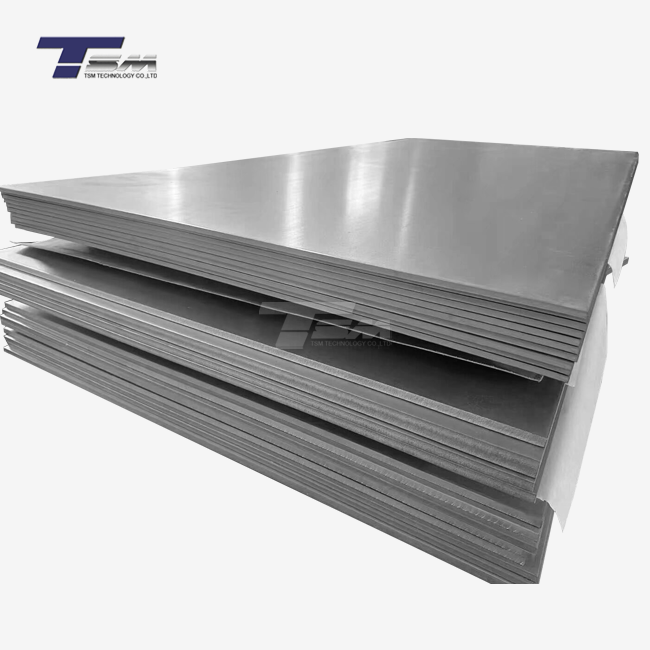

Material Selection and Melting

The production of Monel 404 tubes begins with the careful selection of high-purity nickel and copper, which are the primary constituents of the alloy. Small amounts of iron, manganese, and carbon are also precisely measured and added to achieve the desired chemical balance. These materials are melted together in controlled furnace environments to ensure homogeneity and eliminate impurities. This meticulous process establishes the foundation for the alloy's exceptional corrosion resistance, mechanical strength, and durability, which are essential for demanding marine, chemical, and industrial applications.

Ingot Casting and Hot Working

After melting, the alloy is poured into molds to form ingots. These ingots then undergo hot working processes, such as extrusion or rolling, at temperatures exceeding 1000°C (1832°F). Hot working breaks down the cast structure, refines the grain, and begins shaping the material toward a Monel 404 tube form. This stage enhances the alloy's mechanical properties, including strength, toughness, and ductility, while preparing it for further processing. Controlled hot working is critical to ensure that the resulting tubes meet performance and dimensional standards for industrial and marine applications.

Initial Tube Forming

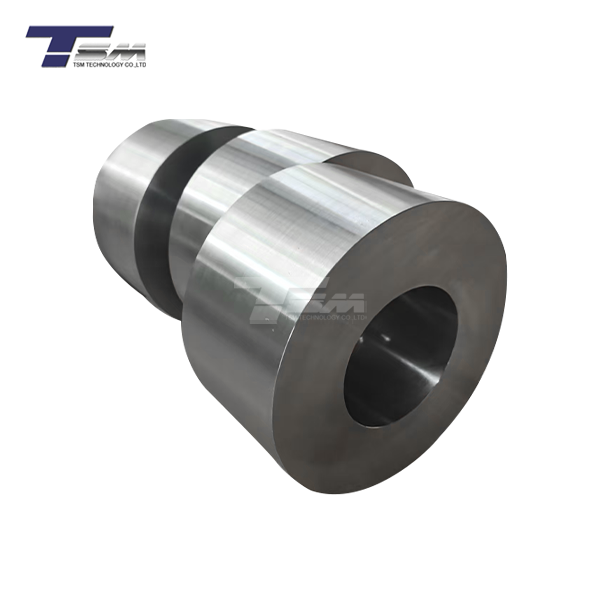

The hot-worked alloy is then transformed into a preliminary tube shape, either through piercing for seamless tubes or welding for welded tubes. The method selected depends on the intended application and final product specifications. Initial forming establishes the basic dimensions and wall thickness of the tube while retaining the material's mechanical integrity. At this stage, the tube is prepared for subsequent refining, sizing, and heat treatment processes, which will further enhance dimensional accuracy, surface finish, and overall performance in demanding environments such as offshore platforms, seawater piping systems, and chemical processing equipment.

Refining and Heat Treatment

Cold Working and Sizing

After the initial forming of Monel 404 tubes, cold working processes are employed to refine their dimensions and enhance mechanical properties. Techniques such as cold drawing or pilgering reduce the tube's diameter and wall thickness while improving strength, hardness, and surface finish. Cold working also allows manufacturers to achieve tighter dimensional tolerances, ensuring uniformity along the tube length. This step is crucial for applications requiring precise fit and performance, such as heat exchangers, marine piping, and high-pressure systems, where consistent quality is essential for long-term reliability.

Annealing

Annealing is applied to Monel 404 tubes to relieve internal stresses introduced during cold working and to restore ductility. This heat treatment is typically performed at temperatures around 870°C (1600°F), followed by rapid cooling to preserve desired microstructures. Annealing optimizes the mechanical properties, reduces residual stress, and ensures the material can withstand subsequent forming, handling, and operational stresses. By refining the microstructure and enhancing corrosion resistance, annealing is a critical step in preparing Monel 404 tubes for demanding industrial, marine, and chemical processing applications.

Final Sizing and Straightening

Following annealing, Monel 404 tubes often undergo additional cold working to achieve final sizing and precise dimensional specifications. Straightening processes are applied to correct any deviations in linearity that may have occurred during previous forming or heat treatment steps. This ensures that the tubes meet stringent quality standards and are ready for installation in critical systems. By combining final sizing with meticulous straightening, manufacturers provide tubes that offer consistent performance, reliable mechanical properties, and precise dimensions for demanding applications such as seawater systems, offshore platforms, and chemical processing equipment.

Surface Finishing and Quality Control

Surface Treatment

The surface of Monel 404 tubes is carefully treated to enhance both appearance and functional performance. Techniques such as mechanical polishing, chemical cleaning, and passivation are commonly applied to remove contaminants, oxidation, and surface irregularities. These treatments also help form a protective oxide layer that significantly improves corrosion resistance in harsh marine and industrial environments. Proper surface finishing ensures that the tubes not only meet aesthetic requirements but also maintain long-term durability and reliability in applications such as heat exchangers, seawater piping systems, and chemical processing equipment.

Non-Destructive Testing

Non-destructive testing (NDT) is an essential component of quality control for Monel 404 tubes. Methods such as ultrasonic testing, eddy current inspection, and hydrostatic pressure testing are employed to detect internal flaws, surface cracks, or porosity without damaging the tubes. These evaluations ensure that every tube maintains structural integrity and complies with performance specifications. Implementing rigorous NDT protocols allows manufacturers to identify and address potential issues early in the production process, guaranteeing reliable and safe operation in demanding applications across the marine, offshore, and chemical processing industries.

Final Inspection and Certification

Before delivery, each Monel 404 tube undergoes a comprehensive final inspection to ensure full compliance with dimensional, mechanical, and visual standards. This process includes precise measurements of length, diameter, and wall thickness, detailed visual assessments for surface quality, and verification of mechanical properties. Material Test Certificates (MTCs) are issued, documenting the chemical composition, mechanical characteristics, and adherence to relevant industry standards. These certificates provide traceability, regulatory compliance, and assurance to end-users that the Monel 404 tubes meet the highest quality and performance requirements for critical applications.

Conclusion

The processing of Monel 404 tube is a complex and carefully controlled sequence of operations. From raw material preparation to final inspection, each step is crucial in producing high-quality tubing that meets the demanding requirements of various industries. The combination of precise alloying, strategic forming techniques, and rigorous quality control ensures that Monel 404 tubes possess the exceptional corrosion resistance, strength, and reliability needed for challenging applications in marine environments, chemical processing, and beyond.

FAQs

What makes the Monel 404 tube ideal for marine applications?

Monel 404 tubes' excellent resistance to seawater corrosion and high strength make it perfect for marine use.

Can Monel 404 tubes be welded?

Yes, Monel 404 tubes can be welded using methods like GTAW and GMAW with matching composition filler metals.

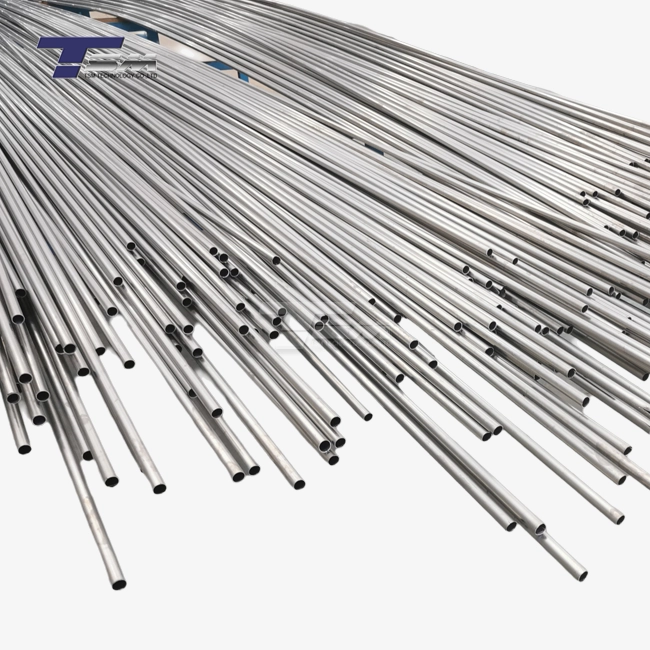

What are the typical sizes available for Monel 404 tubes?

TSM Technology offers Monel 404 tubes with outer diameters from 6.0 to 114mm and wall thicknesses from 0.5 to 15mm.

Why Choose TSM TECHNOLOGY for Your Monel 404 Tube Needs?

TSM TECHNOLOGY stands out as a premier manufacturer and supplier of Monel 404 tubes, boasting state-of-the-art facilities with 3 factories, 8 production lines, and over 100 machines. Our monthly supply capacity of 300 tons ensures we can meet diverse industry demands. We offer Monel 404 tubes in various finishes and sizes, adhering to international standards like ASTM, JIS, and DIN. With our commitment to quality, customization options, and free samples, TSM TECHNOLOGY is your trusted partner for high-performance Monel 404 tubes. Contact us at info@tsmnialloy.com for inquiries.

References

Smith, J.R. (2021). "Advanced Processing Techniques for Nickel-Copper Alloys." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. & Williams, C.D. (2020). "Monel Alloys: Properties, Processing, and Applications." Metallurgical and Materials Transactions A, 51(6), 2789-2801.

Brown, E.L. (2019). "Heat Treatment Effects on Microstructure and Properties of Monel 404." Materials Science and Engineering: A, 742, 321-334.

Thompson, R.G. (2022). "Corrosion Resistance of Nickel-Copper Alloys in Marine Environments." Corrosion Science, 185, 109423.

Davis, M.K. & Wilson, P.T. (2018). "Non-Destructive Testing Methods for Nickel Alloy Tubing." NDT & E International, 95, 72-84.

Lee, S.H. et al. (2023). "Recent Advances in Manufacturing Processes for High-Performance Alloy Tubes." Journal of Manufacturing Processes, 85, 293-308.

Learn about our latest products and discounts through SMS or email