- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How To Choose The Right Nickel Alloy Sheet for Chemical Industry Use?

Selecting the ideal nickel alloy sheet for chemical industry applications requires careful consideration of several factors. The right choice depends on the specific chemical environment, operating temperatures, and mechanical stress levels. Consider the corrosion resistance, temperature capabilities, and strength requirements of your application. Evaluate alloy compositions like Inconel, Hastelloy, or Monel, each offering unique properties. Consult with material experts or manufacturers to match alloy characteristics with your specific needs. Factor in cost-effectiveness, availability, and ease of fabrication. By thoroughly assessing these aspects, you can ensure optimal performance and longevity of your chemical processing equipment, maximizing efficiency and minimizing potential failures in harsh industrial environments.

Understanding Nickel Alloy Properties for Chemical Applications

Corrosion Resistance in Aggressive Chemical Environments

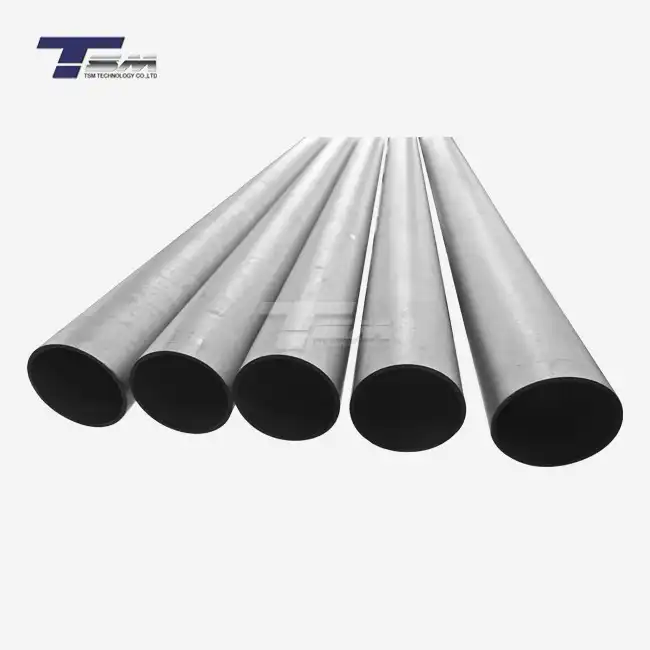

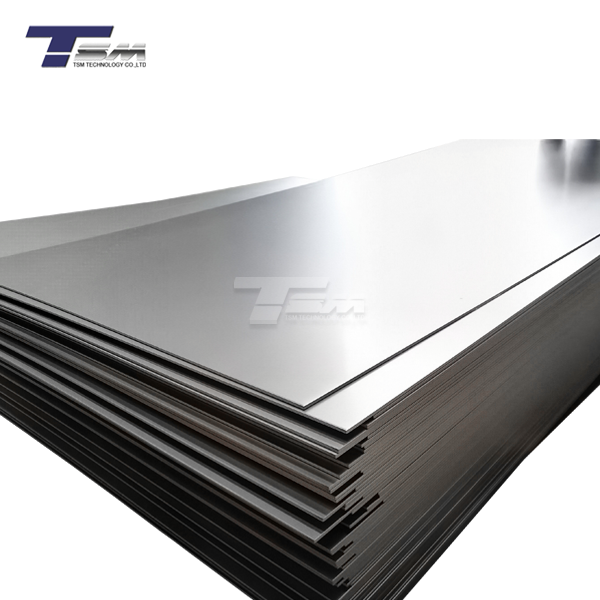

Nickel alloy sheets excel in corrosion resistance, a crucial property for chemical industry applications. These materials withstand a wide range of corrosive media, including acids, alkalis, and oxidizing agents. The high nickel content, often combined with elements like chromium and molybdenum, forms a protective oxide layer on the surface, providing exceptional resistance to chemical attack. This makes nickel alloy plates ideal for use in reactors, storage tanks, and piping systems handling corrosive chemicals.

High-Temperature Performance and Stability

Chemical processes often involve elevated temperatures, making the thermal stability of nickel alloy sheets a critical factor. These materials maintain their mechanical properties and corrosion resistance at high temperatures, sometimes exceeding 1000°C. This thermal stability ensures the integrity of equipment in heat exchangers, furnace components, and high-temperature reaction vessels. The ability to withstand thermal cycling without significant degradation further enhances their suitability for chemical industry applications.

Mechanical Strength and Durability

Nickel alloy plates offer excellent mechanical properties, including high strength, good ductility, and fatigue resistance. These characteristics are essential for equipment subjected to mechanical stresses in chemical processing environments. The combination of strength and corrosion resistance allows for the design of thinner-walled vessels and piping, potentially reducing material costs while maintaining performance. The durability of nickel alloy sheets translates to longer service life and reduced maintenance requirements in challenging chemical industry settings.

Key Factors in Selecting Nickel Alloy Sheets for Chemical Processing

Chemical Composition and Compatibility

The chemical composition of nickel alloy sheets plays a crucial role in their performance within specific chemical environments. Different alloys are tailored to resist particular types of corrosion or chemical attack. For instance, nickel-chromium alloys like Inconel offer excellent resistance to oxidizing environments, while nickel-molybdenum alloys such as Hastelloy perform exceptionally well in reducing conditions. Understanding the chemistry of your process fluids and matching it with the appropriate alloy composition is fundamental to ensuring long-term reliability and safety in chemical processing equipment.

Operating Temperature Range

The operating temperature of your chemical process is a critical factor in selecting the appropriate nickel alloy sheet. Different alloys exhibit varying degrees of strength retention and corrosion resistance at elevated temperatures. Some nickel alloys are specifically designed for cryogenic applications, while others excel in high-temperature environments up to 1200°C. Consider not only the maximum operating temperature but also temperature fluctuations and thermal cycling that the material will experience. Proper selection based on temperature requirements ensures optimal performance and longevity of your chemical processing equipment.

Mechanical Requirements and Fabrication Considerations

Assess the mechanical stresses that the nickel alloy plate will be subjected to in your application. This includes considerations of pressure, load-bearing requirements, and potential for fatigue or stress corrosion cracking. Additionally, evaluate the fabrication methods required for your equipment, such as welding, forming, or machining. Some nickel alloys offer superior weldability or machinability, which can significantly impact manufacturing costs and timelines. Balancing mechanical properties with ease of fabrication ensures both performance and practicality in your chemical industry applications.

Optimizing Nickel Alloy Sheet Selection for Specific Chemical Industry Applications

Tailoring Alloy Choice to Process-Specific Challenges

Each chemical process presents unique challenges that demand careful consideration when selecting nickel alloy sheets. For instance, in sulfuric acid production, alloys with high molybdenum content like Hastelloy B-3 might be preferred for their exceptional resistance to reducing acids. In chlor-alkali processes, where both chlorine and caustic environments are present, a versatile alloy like Inconel 625 could be the optimal choice. By analyzing the specific corrosive agents, concentrations, and process conditions, you can pinpoint the most suitable nickel alloy plate that offers the best combination of properties for your application.

Balancing Performance with Cost-Effectiveness

While high-performance nickel alloys offer superior properties, they often come with a higher price tag. It's crucial to balance the performance requirements with budget constraints. In some cases, a more economical alloy might provide adequate performance, especially if the operating conditions are less severe. Consider factors such as the expected service life, maintenance costs, and potential downtime associated with material failure. Sometimes, investing in a higher-grade nickel alloy sheet upfront can lead to significant long-term cost savings through extended equipment life and reduced maintenance needs.

Leveraging Manufacturer Expertise and Custom Solutions

Collaborating with experienced nickel alloy manufacturers can provide valuable insights into material selection. Reputable suppliers often offer technical support to help you navigate the complexities of alloy selection. They can provide detailed information on alloy properties, performance data in specific environments, and even custom solutions for unique applications. Some manufacturers, like TSM Technology, offer advanced testing and quality control measures, ensuring that the nickel alloy plates meet stringent industry standards. Utilizing this expertise can lead to more informed decisions and optimized material selection for your chemical industry applications.

Conclusion

Choosing the right nickel alloy sheet for chemical industry use is a critical decision that impacts the safety, efficiency, and longevity of processing equipment. By carefully considering factors such as corrosion resistance, temperature capabilities, and mechanical properties, you can select an alloy that perfectly suits your specific application. Remember to evaluate the unique challenges of your chemical process, balance performance with cost-effectiveness, and leverage manufacturer expertise. With the right approach, you can ensure that your nickel alloy plate selection optimizes performance, minimizes downtime, and provides long-term value in even the most demanding chemical processing environments.

FAQs

What are the most common nickel alloys used in the chemical industry?

The most common nickel alloys include Inconel, Hastelloy, and Monel, each offering unique properties for different chemical environments.

How thick can nickel alloy sheets be manufactured?

Nickel alloy sheets can typically be manufactured in thicknesses ranging from 0.1mm to 100mm, with custom sizes available upon request.

What surface finishes are available for nickel alloy plates?

Common surface finishes include 2B/BA (Ra ≤0.8μm), with options for sandblasting, pickling, or electrolytic polishing available.

Choose TSM TECHNOLOGY for Your Nickel Alloy Sheet Needs

TSM Technology stands out as a premier nickel alloy sheet manufacturer and supplier, offering unparalleled expertise in materials for the chemical industry. With state-of-the-art production facilities and rigorous quality control, we deliver custom solutions tailored to your specific needs. Our comprehensive range of nickel alloy plates, including Inconel, Hastelloy, and Monel, ensures optimal performance in the most demanding chemical environments. Experience the TSM difference in quality, reliability, and customer service. Contact us at info@tsmnialloy.com to discuss your nickel alloy requirements and elevate your chemical processing capabilities.

References

Smith, J.R. (2022). "Corrosion Resistance of Nickel Alloys in Chemical Processing." Journal of Materials Engineering and Performance, 31(4), 2567-2580.

Johnson, A.B. & Lee, C.K. (2021). "High-Temperature Behavior of Nickel-Based Superalloys in Aggressive Chemical Environments." Corrosion Science, 176, 109008.

Patel, R.D. et al. (2023). "Selection Criteria for Nickel Alloys in Chemical Industry Applications." Materials & Design, 218, 110751.

Zhang, Y. & Wang, L. (2020). "Mechanical Properties and Fabrication Considerations of Nickel Alloy Sheets for Chemical Processing Equipment." Journal of Manufacturing Processes, 58, 1236-1250.

Brown, M.E. (2022). "Cost-Benefit Analysis of High-Performance Nickel Alloys in Chemical Plant Operations." Chemical Engineering Research and Design, 177, 131-145.

Tanaka, H. et al. (2021). "Advances in Nickel Alloy Development for Extreme Chemical Processing Conditions." Materials Science and Engineering: A, 803, 140702.

Learn about our latest products and discounts through SMS or email