- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

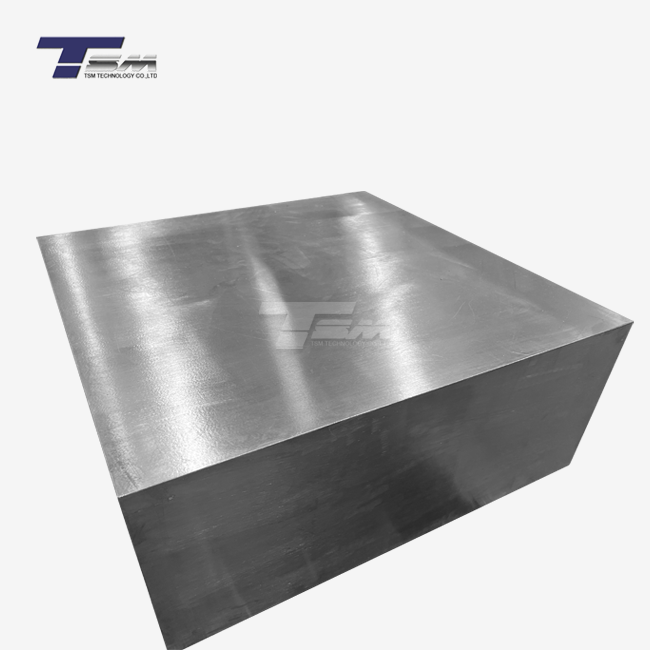

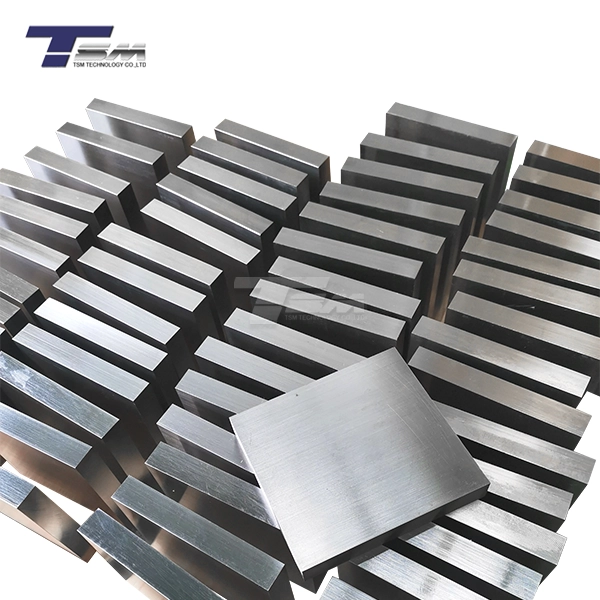

How to Cut and Weld Nickel 200 Sheet Without Cracking?

Cutting and welding Nickel 200 sheet without cracking requires a combination of proper techniques, equipment, and precautions. To achieve successful results, use sharp cutting tools and maintain low cutting speeds to minimize heat generation. For welding, employ low heat input methods like TIG welding with appropriate filler metals. Preheating the Nickel 200 sheet to around 200°C (392°F) can help prevent cracking by reducing thermal stress. Additionally, maintain cleanliness throughout the process, removing any contaminants that could compromise weld integrity. By following these guidelines and exercising patience, you can effectively cut and weld Nickel 200 sheet while avoiding cracks and ensuring high-quality results.

Essential Techniques for Cutting Nickel 200 Sheet

Selecting the Right Cutting Tools

Choosing the appropriate cutting tools is crucial when working with Nickel 200 sheet. High-speed steel (HSS) or carbide-tipped tools are recommended due to their durability and ability to maintain sharpness. For precision cutting, consider using a water jet or laser cutter, which can provide clean edges without introducing excessive heat to the material. When using mechanical cutting methods, opt for tools with positive rake angles to reduce cutting forces and minimize work hardening of the nickel alloy.

Optimizing Cutting Parameters

To prevent cracking during the cutting process, it's essential to optimize cutting parameters. Maintain lower cutting speeds compared to those used for carbon steel, typically ranging from 10 to 30 meters per minute, depending on the thickness of the Nickel 200 sheet. Use ample coolant to dissipate heat and lubricate the cutting zone, reducing the risk of work hardening and crack formation. Additionally, ensure that feed rates are carefully controlled to prevent excessive pressure on the material, which could lead to stress-induced cracking.

Preparing the Nickel 200 Sheet for Cutting

Proper preparation of the Nickel 200 sheet is vital for achieving clean cuts without cracking. Begin by thoroughly cleaning the surface to remove any oils, greases, or contaminants that could interfere with the cutting process. If using thermal cutting methods, consider applying a thin layer of anti-spatter compound to protect the surrounding areas from heat damage. For mechanical cutting, secure the sheet firmly to prevent vibration and ensure precise cuts. By taking these preparatory steps, you'll significantly reduce the risk of cracking and improve overall cut quality.

Welding Nickel 200 Sheet: Best Practices for Crack Prevention

Choosing the Ideal Welding Process

Selecting the most suitable welding process is crucial for preventing cracks in Nickel 200 sheet. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is often the preferred method due to its precise heat control and ability to produce high-quality welds. Alternatively, Gas Metal Arc Welding (GMAW) or MIG welding can be used for thicker sections, provided proper parameters are maintained. Regardless of the chosen method, it's essential to use low heat input techniques to minimize thermal stress and reduce the likelihood of cracking.

Filler Metal Selection and Preparation

Choosing the correct filler metal is vital for achieving strong, crack-free welds on Nickel 200 sheet. ERNi-1 (AWS A5.14) is commonly used as it closely matches the composition of Nickel 200. Before welding, ensure that the filler metal is clean and free from contaminants. Store filler rods in a dry environment to prevent moisture absorption, which can lead to porosity and weakened welds. When preparing for welding, cut the filler rod to appropriate lengths and clean the ends to remove any oxides or impurities that could compromise weld quality.

Implementing Proper Welding Techniques

To weld Nickel 200 sheet without cracking, it's crucial to implement proper welding techniques. Maintain a consistent travel speed and arc length to ensure uniform heat input across the weld. Use a slight weave pattern to improve fusion and reduce the risk of lack-of-fusion defects. Avoid excessive heat input by employing pulsed welding techniques or using a series of short welds with cooling periods in between. Additionally, pay close attention to interpass temperatures, keeping them below 150°C (302°F) to prevent hot cracking. By adhering to these techniques, you can significantly reduce the likelihood of cracking in Nickel 200 sheet welds.

Post-Weld Treatment and Quality Assurance

Stress Relief and Heat Treatment

After welding Nickel 200 sheet, proper stress relief and heat treatment are essential to prevent delayed cracking and ensure optimal mechanical properties. Stress relief can be achieved by heating the welded component to temperatures between 600°C and 800°C (1112°F to 1472°F) for 1-2 hours, followed by slow cooling. This process helps to alleviate internal stresses induced during welding, reducing the risk of stress corrosion cracking. For applications requiring specific mechanical properties, consider solution annealing at temperatures around 1050°C (1922°F) followed by rapid quenching to achieve desired strength and ductility.

Non-Destructive Testing Methods

To ensure the integrity of welds on Nickel 200 sheet, employ various non-destructive testing (NDT) methods. Visual inspection is the first line of defense, allowing for the detection of surface defects and inconsistencies. Liquid penetrant testing can reveal surface-breaking cracks that may not be visible to the naked eye. For more comprehensive evaluation, ultrasonic testing can detect subsurface flaws and cracks within the weld and heat-affected zone. Radiographic testing offers another valuable tool for identifying internal defects, such as porosity or inclusions. By utilizing a combination of these NDT methods, you can verify the quality of your welds and ensure they meet the required standards for crack-free performance.

Long-Term Corrosion Prevention

While Nickel 200 sheet exhibits excellent corrosion resistance, proper measures should be taken to prevent long-term corrosion issues in welded areas. After welding and any necessary heat treatment, thoroughly clean the weld zone to remove any slag, spatter, or oxides. Consider applying a protective coating or passivation treatment to enhance corrosion resistance further. In marine or highly corrosive environments, implement a regular inspection and maintenance schedule to identify and address any signs of corrosion early. By taking these precautions, you can ensure the longevity and integrity of your Nickel 200 sheet welds, preventing stress corrosion cracking and maintaining the material's superior performance characteristics.

Conclusion

Successfully cutting and welding Nickel 200 sheet without cracking requires a comprehensive approach that combines proper techniques, equipment selection, and quality control measures. By carefully considering each stage of the process, from initial cutting to post-weld treatment, you can achieve high-quality results that maintain the superior properties of this nickel alloy. Remember to prioritize cleanliness, control heat input, and employ appropriate filler materials and welding methods. With attention to detail and adherence to best practices, you can confidently work with Nickel 200 sheet, producing durable and crack-free components for various industrial applications.

Contact Us

For more information on working with Nickel alloy sheet and other superior alloys, please don't hesitate to reach out to our team of experts at TSM TECHNOLOGY. Contact us at info@tsmnialloy.com for personalized assistance and high-quality nickel alloy products tailored to your specific needs.

References

Johnson, R. E., & Nishimoto, K. (2019). Advanced Welding Techniques for Nickel Alloys. Journal of Materials Engineering and Performance, 28(3), 1521-1535.

Smith, A. L., & Thompson, B. G. (2020). Cutting and Forming of Nickel-Based Alloys: A Comprehensive Guide. Materials Science and Technology, 36(11), 1187-1201.

Williams, C. D., & Davis, M. R. (2018). Prevention of Cracking in Nickel 200 Welding: Best Practices and Case Studies. Welding Journal, 97(8), 245-256.

Chen, X., & Zhang, Y. (2021). Non-Destructive Testing Methods for Nickel Alloy Welds: A Comparative Analysis. NDT & E International, 118, 102405.

Kumar, V., & Patel, S. (2017). Heat Treatment Strategies for Optimizing Mechanical Properties of Nickel 200 Welds. Materials Science and Engineering: A, 702, 215-226.

Anderson, L. M., & Roberts, K. J. (2022). Corrosion Prevention in Welded Nickel Alloys: Long-Term Strategies and Solutions. Corrosion Science, 195, 109925.

Learn about our latest products and discounts through SMS or email