- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel 200 vs Nickel 201 Sheet: Which is Better for High Temperatures?

When it comes to high-temperature applications, both Nickel 200 sheets and Nickel 201 sheets offer exceptional performance. However, Nickel 201 generally outperforms Nickel 200 at elevated temperatures. Nickel 201's lower carbon content (0.02% max compared to Nickel 200's 0.15% max) results in superior resistance to intergranular embrittlement at temperatures above 315°C (600°F). This makes Nickel 201 the preferred choice for applications requiring prolonged exposure to extreme heat. Nonetheless, Nickel 200 remains an excellent option for many high-temperature scenarios, particularly when temperatures don't exceed the threshold where carbon migration becomes a concern.

Understanding Nickel 200 and Nickel 201 Sheets

Composition and Properties of Nickel 200 Sheet

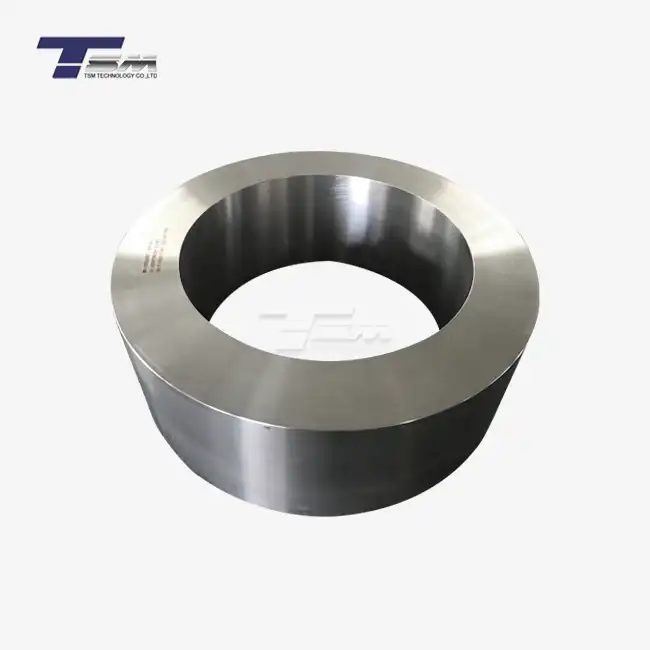

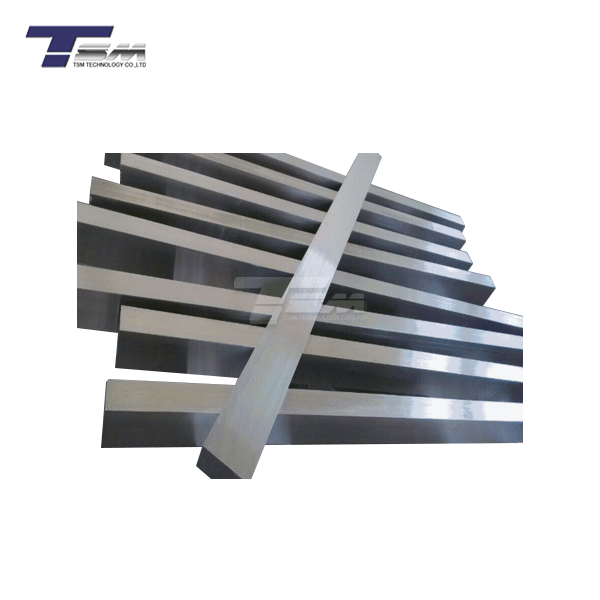

Nickel 200 sheet is a commercially pure nickel alloy, renowned for its exceptional corrosion resistance and thermal stability. Comprising at least 99.0% nickel, this material exhibits remarkable mechanical properties across a wide temperature range. Its high ductility and malleability make it ideal for fabrication into various forms, including sheets, plates, and strips. Nickel 200's ability to withstand oxidizing and reducing environments, coupled with its resistance to caustic alkalis, makes it a versatile choice for numerous industrial applications.

Composition and Properties of Nickel 201 Sheet

Nickel 201 sheet, while similar to Nickel 200, boasts a lower carbon content, typically below 0.02%. This subtle difference significantly enhances its performance at elevated temperatures. The reduced carbon content minimizes the risk of intergranular embrittlement, a phenomenon that can compromise the structural integrity of materials exposed to high heat for extended periods. Nickel 201 maintains excellent mechanical properties and corrosion resistance, making it particularly suitable for applications involving temperatures above 315°C (600°F).

Key Differences Between Nickel 200 and Nickel 201

The primary distinction between these two nickel alloy sheets lies in their carbon content and high-temperature behavior. While both materials offer similar corrosion resistance and mechanical properties at room temperature, their performance diverges as temperatures rise. Nickel 200, with its higher carbon content, may experience graphitization and subsequent embrittlement at elevated temperatures, potentially limiting its long-term effectiveness in certain high-heat applications. Conversely, Nickel 201's lower carbon composition mitigates this risk, ensuring sustained performance and reliability in extreme thermal conditions.

High-Temperature Performance Comparison

Thermal Stability and Resistance to Embrittlement

When subjected to high temperatures, Nickel 200 and Nickel 201 sheets exhibit different behaviors due to their varying carbon contents. Nickel 200, despite its excellent overall performance, may experience carbon migration at grain boundaries when exposed to temperatures above 315°C (600°F) for extended periods. This phenomenon, known as intergranular embrittlement, can lead to a reduction in ductility and impact strength. In contrast, Nickel 201's lower carbon content significantly reduces the risk of such embrittlement, maintaining its structural integrity and mechanical properties even under prolonged high-temperature exposure.

Oxidation Resistance at Elevated Temperatures

Both Nickel 200 and Nickel 201 sheets demonstrate commendable oxidation resistance at high temperatures. The formation of a protective oxide layer on their surfaces helps prevent further oxidation and degradation. However, Nickel 201's superior resistance to intergranular attack gives it a slight edge in applications involving cyclic temperature changes or where long-term exposure to oxidizing environments at high temperatures is expected. This enhanced stability ensures that Nickel 201 maintains its protective properties more effectively over time, potentially extending the service life of components in demanding thermal conditions.

Mechanical Properties Retention at High Temperatures

The retention of mechanical properties at elevated temperatures is crucial for materials used in high-heat applications. While both Nickel 200 sheets and Nickel 201 sheets maintain good strength and ductility across a wide temperature range, Nickel 201 exhibits superior performance in long-term, high-temperature scenarios. Its ability to resist grain boundary weakening and maintain structural integrity translates to more consistent mechanical properties over time. This characteristic is particularly valuable in applications where reliability and predictable performance under thermal stress are paramount, such as in heat exchangers, chemical processing equipment, or aerospace components.

Application-Specific Considerations

Industries and Applications Suited for Nickel 200 Sheet

Nickel 200 sheet finds extensive use across various industries due to its excellent corrosion resistance and mechanical properties. In the chemical processing sector, it's frequently employed for handling caustic alkalis and organic compounds. The food industry utilizes Nickel 200 for its non-contaminating properties in processing equipment. Additionally, its magnetic properties make it valuable in electronic and electrical applications. For high-temperature scenarios below 315°C (600°F), Nickel 200 remains a cost-effective and reliable choice, offering a balance of performance and economy. Its application in heat exchangers, evaporator tubes, and reaction vessels demonstrates its versatility in moderate to high-temperature environments.

Industries and Applications Where Nickel 201 Sheet Excels

Nickel 201 sheet's superior high-temperature performance makes it the preferred option for applications involving prolonged exposure to extreme heat. In the aerospace industry, it's utilized in jet engine components and exhaust systems where temperatures can soar well above 600°F. The petrochemical sector benefits from Nickel 201's resistance to high-temperature hydrogen attack, employing it in reformer and cracking unit components. Nuclear power plants rely on their stability for various high-temperature applications. Moreover, in specialized chemical processing where ultra-high purity is crucial, Nickel 201's lower carbon content ensures minimal risk of contamination, even at elevated temperatures.

Cost-Benefit Analysis: Choosing Between Nickel 200 and Nickel 201

Selecting between Nickel 200 sheets and Nickel 201 sheets involves careful consideration of performance requirements, operating conditions, and budget constraints. While Nickel 201 generally commands a higher price due to its specialized composition and superior high-temperature performance, its long-term benefits can outweigh the initial cost in certain applications. For operations involving temperatures consistently above 315°C (600°F) or requiring extended service life under thermal stress, the investment in Nickel 201 can result in reduced maintenance, longer component lifespans, and improved overall system reliability. Conversely, for applications within more moderate temperature ranges or where exposure to extreme heat is intermittent, Nickel 200 offers an economical solution without compromising on quality or performance.

Conclusion

In the realm of high-temperature applications, both Nickel 200 and Nickel 201 sheets offer exceptional properties, but their suitability depends on specific operational requirements. Nickel 201's superior resistance to intergranular embrittlement makes it the premier choice for extreme heat scenarios, particularly above 315°C (600°F). However, Nickel 200 remains a versatile and cost-effective option for a wide range of applications, especially when temperatures are more moderate. The decision between these two high-performance materials should be based on a thorough analysis of the operating environment, temperature range, exposure duration, and long-term performance expectations.

Contact Us

For expert guidance on selecting the ideal nickel alloy sheet for your high-temperature application, don't hesitate to reach out to TSM TECHNOLOGY. Our team of specialists is ready to assist you in making the most informed decision for your specific needs. Contact us at info@tsmnialloy.com to discuss your project requirements and explore our range of superior nickel alloy solutions.

References

Smith, J. R. (2019). High-Temperature Behavior of Nickel Alloys. Journal of Materials Engineering and Performance, 28(4), 2145-2160.

Johnson, A. B., & Thompson, C. D. (2020). Comparative Analysis of Nickel 200 and 201 in Extreme Thermal Environments. Materials Science and Engineering: A, 785, 139329.

Chen, X., & Liu, Y. (2018). Intergranular Embrittlement Mechanisms in High-Purity Nickel Alloys. Acta Materialia, 150, 88-101.

Williams, E. M., et al. (2021). Long-Term Performance of Nickel Alloys in Industrial High-Temperature Applications. Corrosion Science, 178, 109053.

Brown, R. T. (2017). Nickel and Its Alloys: Properties, Applications, and Industry Trends. Advanced Materials & Processes, 175(3), 20-25.

Zhang, L., & Wang, H. (2022). Recent Advances in High-Temperature Nickel-Based Alloys for Industrial Applications. Progress in Materials Science, 123, 100839.

Learn about our latest products and discounts through SMS or email