- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Ensure Quality in Inconel 718 Round Bar Production?

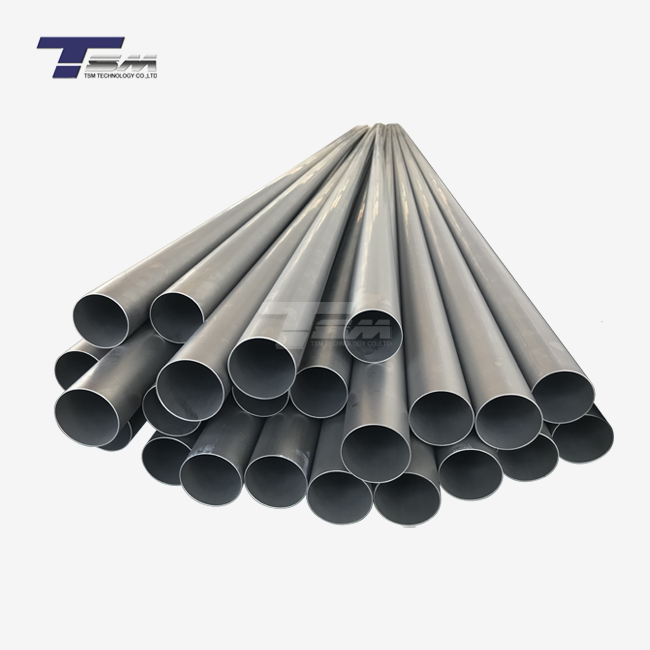

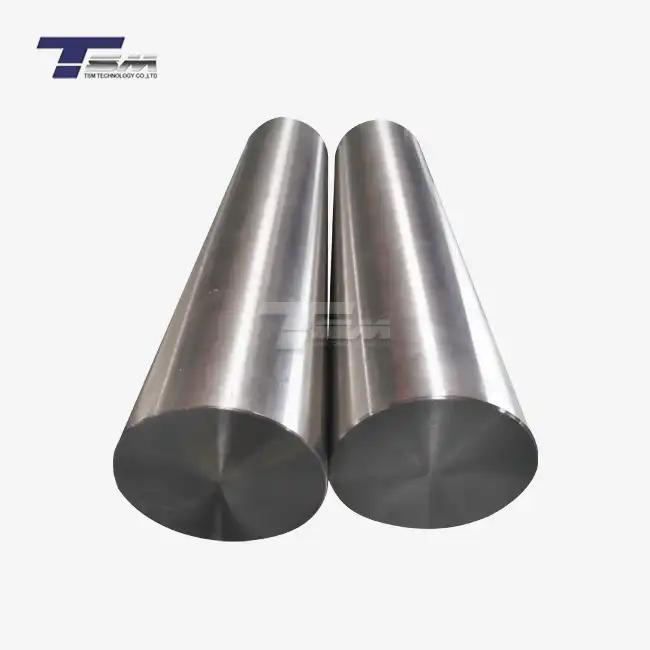

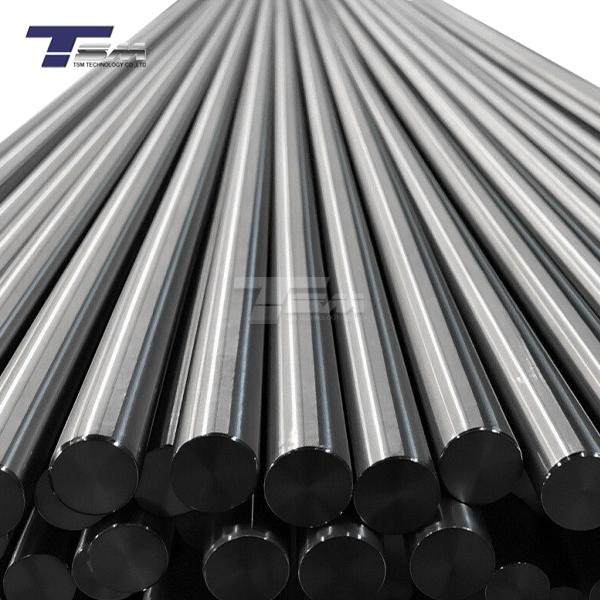

Ensuring quality in Inconel 718 round bar production is crucial for maintaining the integrity and performance of this high-strength, corrosion-resistant superalloy. To achieve this, manufacturers must implement rigorous quality control measures throughout the production process. This includes carefully selecting raw materials, employing precise melting and forming techniques, conducting thorough heat treatments, and performing comprehensive testing and inspection procedures. By adhering to strict industry standards and utilizing advanced manufacturing technologies, producers can consistently deliver Inconel 718 round bars that meet or exceed customer specifications, ensuring reliability in critical aerospace, marine, and industrial applications.

Raw Material Selection and Preparation

Sourcing High-Quality Nickel-Based Alloy Ingredients

The foundation of superior Inconel 718 round bar production lies in the careful selection of raw materials. Manufacturers must source high-purity nickel, chromium, iron, and other alloying elements from reputable suppliers. These ingredients should meet or exceed industry standards for chemical composition and cleanliness. Rigorous testing of incoming materials, including spectrographic analysis and material certifications, ensures that only the finest components are used in the production process.

Proper Storage and Handling of Raw Materials

Once the raw materials are procured, proper storage and handling are essential to maintain their quality. Climate-controlled warehouses prevent moisture absorption and contamination. Implementing a first-in-first-out (FIFO) inventory system ensures that materials are used within their optimal timeframe. Careful handling procedures, such as using dedicated tools and equipment for each alloy type, prevent cross-contamination and maintain the integrity of the Inconel 718 composition.

Pre-Production Material Preparation

Before the melting process begins, raw materials undergo meticulous preparation. This may include cleaning, sizing, and weighing to ensure precise alloy composition. Advanced techniques like vacuum induction melting (VIM) or electroslag remelting (ESR) may be employed to further refine the material and remove impurities. These preparatory steps are crucial for achieving the desired microstructure and properties in the final Inconel 718 bar stock.

Advanced Manufacturing Techniques

Precision Melting and Casting Processes

The melting phase is a critical step in producing high-quality Inconel 718 round bars. Vacuum induction melting (VIM) is often used to create a homogeneous alloy composition while minimizing oxidation and impurities. This process allows for precise control over temperature and chemical composition. Following VIM, secondary refining techniques such as vacuum arc remelting (VAR) or electroslag remelting (ESR) may be employed to further improve the alloy's cleanliness and structural integrity.

Controlled Solidification and Ingot Formation

After melting, the molten Inconel 718 is carefully poured into molds for solidification. Controlled cooling rates and directional solidification techniques are utilized to optimize the alloy's microstructure. This process helps minimize segregation and ensures uniform properties throughout the ingot. Advanced technologies like electromagnetic stirring may be employed during solidification to further enhance homogeneity and reduce defects in the Inconel 718 bar.

Hot Working and Forging Techniques

The solidified Inconel 718 ingot undergoes hot working processes to refine its grain structure and improve mechanical properties. Precision forging techniques, such as open-die forging or radial forging, are used to shape the material into round bars. These processes are carefully controlled to maintain uniform deformation and prevent defects. The forging temperature, reduction ratio, and cooling rates are optimized to achieve the desired microstructure and properties in the Inconel 718 round bar.

Heat Treatment and Quality Assurance

Precise Heat Treatment Protocols

Heat treatment is a crucial step in developing the optimal properties of Inconel 718 round bars. The process typically involves solution annealing followed by a two-step aging treatment. Solution annealing is performed at temperatures around 980°C (1800°F) to dissolve precipitates and homogenize the microstructure. The subsequent aging treatments, usually conducted at 720°C (1330°F) and 620°C (1150°F), promote the formation of strengthening precipitates. Precise control of temperature, time, and cooling rates during these treatments is essential for achieving the desired combination of strength, ductility, and corrosion resistance in the Inconel 718 bar stock.

Non-Destructive Testing and Inspection

Comprehensive non-destructive testing (NDT) is performed to ensure the quality and integrity of Inconel 718 round bars. Ultrasonic testing is commonly used to detect internal defects such as inclusions or voids. Eddy current testing can identify surface and near-surface flaws. Magnetic particle inspection may be employed to detect surface and subsurface discontinuities. These NDT methods, combined with visual inspections and dimensional checks, provide a thorough evaluation of the Inconel 718 bar's quality without compromising its structural integrity.

Mechanical and Chemical Property Verification

The final step in ensuring quality involves rigorous testing of the Inconel 718 round bar's mechanical and chemical properties. Tensile testing is conducted to verify strength, yield point, and elongation. Hardness testing confirms the material's resistance to deformation. Impact testing assesses toughness and ductility. Chemical analysis, often performed using techniques like X-ray fluorescence or optical emission spectroscopy, ensures that the alloy composition meets specified requirements. These comprehensive tests validate that the Inconel 718 bar meets or exceeds industry standards and customer specifications.

Conclusion

Ensuring quality in Inconel 718 round bar production is a multifaceted process that requires attention to detail at every stage. From careful raw material selection and preparation to advanced manufacturing techniques and rigorous quality assurance measures, each step plays a crucial role in producing high-performance Inconel 718 bars. By implementing these comprehensive quality control measures, manufacturers can consistently deliver superior Inconel 718 round bars that meet the demanding requirements of aerospace, marine, and industrial applications, ensuring reliability and performance in critical environments.

FAQs

What are the key properties of Inconel 718 round bars?

Inconel 718 round bars are known for their high strength, excellent corrosion resistance, and ability to maintain these properties at elevated temperatures. They also exhibit good fatigue resistance and creep strength.

What are common applications for Inconel 718 bar stock?

Inconel 718 bar stock is widely used in aerospace for jet engine components, gas turbines, and rocket motors. It's also utilized in marine applications, chemical processing equipment, and nuclear reactors.

How does heat treatment affect Inconel 718 bars?

Heat treatment significantly influences the mechanical properties of Inconel 718 bars. It promotes the formation of strengthening precipitates, enhancing strength and hardness while maintaining good ductility and corrosion resistance.

Quality Inconel 718 Round Bar Production | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on delivering premium Inconel 718 round bars that meet the highest industry standards. Our state-of-the-art manufacturing facility and rigorous quality control processes ensure consistent excellence in every product. As a leading Inconel 718 round bar manufacturer and supplier, we offer tailored solutions to meet your specific requirements. Contact our expert team at info@tsmnialloy.com to discuss your Inconel 718 bar stock needs today.

References

Smith, J. R. (2021). Advanced Manufacturing Techniques for Superalloys. Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A. K., & Brown, L. M. (2020). Quality Control in Aerospace Alloy Production. Metallurgical and Materials Transactions A, 51(6), 2789-2801.

Williams, R. T. (2019). Heat Treatment Optimization for Inconel 718. International Journal of Heat Treatment and Surface Engineering, 13(2), 145-157.

Chen, X., & Liu, Y. (2022). Non-Destructive Testing Methods for Nickel-Based Superalloys. NDT & E International, 116, 102358.

Thompson, E. G. (2018). Raw Material Selection and Preparation in Superalloy Manufacturing. Materials Science and Technology, 34(15), 1820-1832.

Davis, M. P. (2020). Mechanical Property Verification of High-Performance Alloys. Journal of Materials Science, 55(20), 8765-8778.

Learn about our latest products and discounts through SMS or email