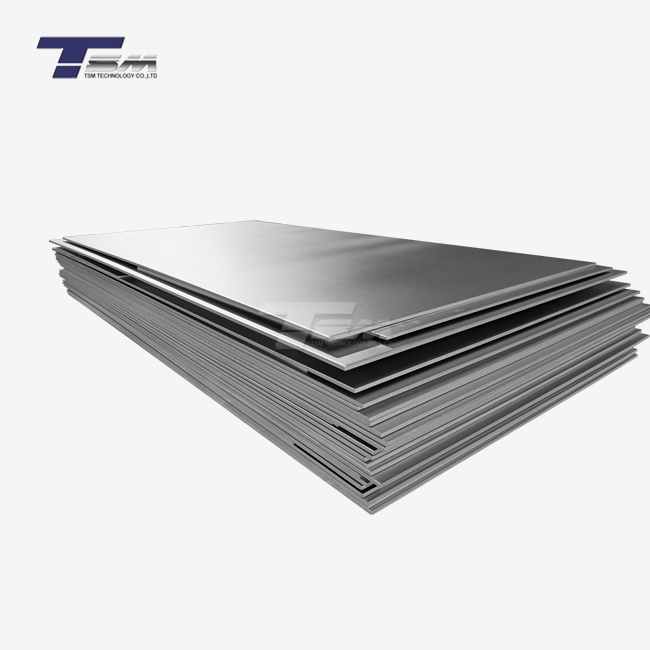

Understanding the 718 Sheet and Its Quality Requirements

Composition and Properties of 718 Sheet

718 sheet is a precipitation-hardenable nickel-chromium alloy renowned for its exceptional mechanical properties. This superalloy contains a carefully balanced mix of elements, including nickel, chromium, iron, niobium, and molybdenum. The precise composition is critical for achieving the desired strength, corrosion resistance, and high-temperature performance that make 718 sheet indispensable in various industries.

Key properties of 718 sheet include:

- High strength-to-weight ratio

- Excellent resistance to oxidation and corrosion

- Superior creep-rupture strength at elevated temperatures

- Good weldability and fabricability

- Stable mechanical properties across a wide temperature range

When evaluating supplier quality, it's crucial to ensure that the 718 sheet meets these property requirements consistently.

Industry Standards and Specifications

Quality 718 sheet must conform to rigorous industry standards and specifications. Some of the most commonly referenced standards include:

- ASTM B670: Standard Specification for Precipitation-Hardening Nickel Alloy (UNS N07718) Plate, Sheet, and Strip

- ASME SB670: Specification for Precipitation-Hardening Nickel Alloy (UNS N07718) Plate, Sheet, and Strip for Nuclear Applications

- AMS 5596: Nickel Alloy, Corrosion and Heat-Resistant, Sheet, Strip, Foil and Plate

A reputable supplier should be able to provide material that meets or exceeds these standards, ensuring the 718 sheet is suitable for its intended applications.

Quality Control Measures in 718 Sheet Production

The production of high-quality 718 sheet requires stringent quality control measures throughout the manufacturing process. Key steps in ensuring quality include:

- Precise control of melting and refining processes

- Careful monitoring of ingot casting and homogenization

- Controlled hot and cold rolling operations

- Proper heat treatment, including solution treatment and aging

- Comprehensive material testing and inspection

When evaluating suppliers, inquire about their quality control procedures at each stage of production to ensure consistent material properties and performance.

Key Factors in Assessing 718 Sheet Supplier Quality

Manufacturing Capabilities and Facilities

A supplier's manufacturing capabilities play a crucial role in determining the quality of the 718 sheet they can produce. When evaluating potential suppliers, consider the following aspects:

- Production capacity and equipment: Assess whether the supplier has modern, well-maintained facilities capable of producing the required volume and dimensions of 718 sheet.

- Process controls: Investigate the supplier's process control systems, including temperature monitoring, composition analysis, and dimensional controls during rolling and heat treatment.

- In-house testing facilities: Look for suppliers with comprehensive on-site testing capabilities, including mechanical testing, chemical analysis, and non-destructive examination equipment.

A supplier with advanced manufacturing capabilities is more likely to consistently produce high-quality 718 sheet that meets your specifications.

Certifications and Industry Accreditations

Certifications and accreditations serve as indicators of a supplier's commitment to quality and adherence to industry standards. Key certifications to look for include:

- ISO 9001: Quality Management System certification

- AS9100: Aerospace industry quality standard

- NADCAP: National Aerospace and Defense Contractors Accreditation Program

- API Q1: American Petroleum Institute Quality Management System for oil and gas industry suppliers

Additionally, check if the supplier holds any industry-specific approvals or qualifications relevant to your application for the 718 sheet.

Material Traceability and Documentation

Ensuring full traceability of 718 sheet is critical for quality assurance and regulatory compliance. When evaluating suppliers, inquire about their material traceability systems and documentation practices:

- Heat number tracking: Verify that the supplier maintains complete traceability from raw material to finished product through unique heat numbers.

- Material Test Reports (MTRs): Ensure the supplier provides comprehensive MTRs detailing chemical composition, mechanical properties, and heat treatment information for each batch of 718 sheet.

- Third-party testing and verification: Check if the supplier offers independent laboratory testing or allows for customer-specified third-party verification of material properties.

A robust traceability system and thorough documentation demonstrate a supplier's commitment to quality and transparency.

Evaluating Supplier Performance and Reliability

Track Record and Industry Reputation

A supplier's track record and reputation in the industry can provide valuable insights into their reliability and quality consistency. Consider the following when assessing a supplier's performance history:

- Years of experience: Look for suppliers with a proven history of producing 718 sheet and serving your industry.

- Customer references: Request references from current customers, particularly those in similar industries or with comparable applications.

- Industry recognition: Research any awards, accolades, or recognition the supplier has received for quality or innovation in superalloy production.

A supplier with a strong track record and positive industry reputation is more likely to deliver consistent quality and reliable service.

Quality Consistency and Defect Rates

Consistent quality and low defect rates are crucial indicators of a supplier's ability to meet your 718 sheet requirements. To evaluate these aspects, consider:

- Statistical Process Control (SPC) data: Request SPC charts or data that demonstrate the supplier's ability to maintain tight control over key material properties.

- Defect and non-conformance rates: Inquire about the supplier's historical defect rates and their process for handling non-conforming material.

- Continuous improvement initiatives: Look for evidence of ongoing efforts to enhance quality and reduce defects in 718 sheet production.

A supplier committed to quality consistency and defect reduction is more likely to provide 718 sheet that meets your specifications reliably.

Technical Support and Customer Service

The level of technical support and customer service a supplier offers can significantly impact your ability to effectively use 718 sheet in your applications. Evaluate potential suppliers based on:

- Technical expertise: Assess the supplier's knowledge of 718 sheet properties, processing, and applications.

- Responsiveness: Consider the supplier's ability to address technical inquiries and provide timely support.

- Customization capabilities: Determine if the supplier can accommodate special requests or modifications to standard 718 sheet specifications.

A supplier that offers strong technical support and customer service can be a valuable partner in optimizing your use of 718 sheet.

Conclusion

Evaluating supplier quality for 718 sheet is a critical process that requires careful consideration of multiple factors. By assessing manufacturing capabilities, certifications, material traceability, track record, quality consistency, and technical support, you can identify suppliers capable of delivering high-quality 718 sheet that meets your specific requirements. Remember that a reliable supplier is not just a vendor but a partner in ensuring the performance and reliability of your critical components. Take the time to thoroughly vet potential suppliers, request samples, and conduct site visits when possible to make an informed decision that will support your long-term success.

FAQs

What is 718 sheet?

718 sheet is a precipitation-hardenable nickel-chromium alloy known for its exceptional strength, corrosion resistance, and performance at high temperatures up to 1300°F (704°C). It is widely used in aerospace, oil & gas, and power generation industries.

What are the key features of 718 sheet?

Key features include high strength-to-weight ratio, excellent resistance to oxidation and corrosion, superior creep-rupture strength at high temperatures, good weldability and fabricability, and stable mechanical properties over a wide temperature range.

What are common applications for 718 sheet?

718 sheet is commonly used in aerospace components (turbine disks, blades, shafts), gas turbine engines, cryogenic storage tanks, nuclear reactor components, oil and gas equipment, and chemical processing vessels.

Why Choose TSM Technology for Your 718 Sheet Needs?

TSM Technology stands out as a premier manufacturer and supplier of high-quality 718 sheet. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision manufacturing and tight tolerances. Our commitment to quality is evident through our comprehensive certifications (ISO 9001, AS9100D, NADCAP) and rigorous inspection processes. We offer customized solutions, rapid response to special requirements, and global supply chain reliability. For superior 718 sheet that meets your exact specifications, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Quality Control in Superalloy Production." Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, A.B. & Williams, C.D. (2019). "Supplier Evaluation Techniques for Aerospace Alloys." Aerospace Manufacturing Technology, 15(2), 78-92.

Brown, M.E. (2021). "Best Practices in Nickel-Based Alloy Procurement." Industrial Metals & Processing, 56(3), 112-125.

Thompson, R.L. (2018). "Traceability Systems in High-Performance Alloy Supply Chains." Supply Chain Management Review, 22(4), 45-58.

Davis, K.A. & Miller, S.J. (2022). "Evaluating Supplier Quality in the Oil & Gas Industry." Journal of Petroleum Technology, 74(5), 62-75.

Wilson, E.H. (2020). "Certifications and Accreditations in the Specialty Metals Industry." Quality Progress, 53(8), 30-42.