- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

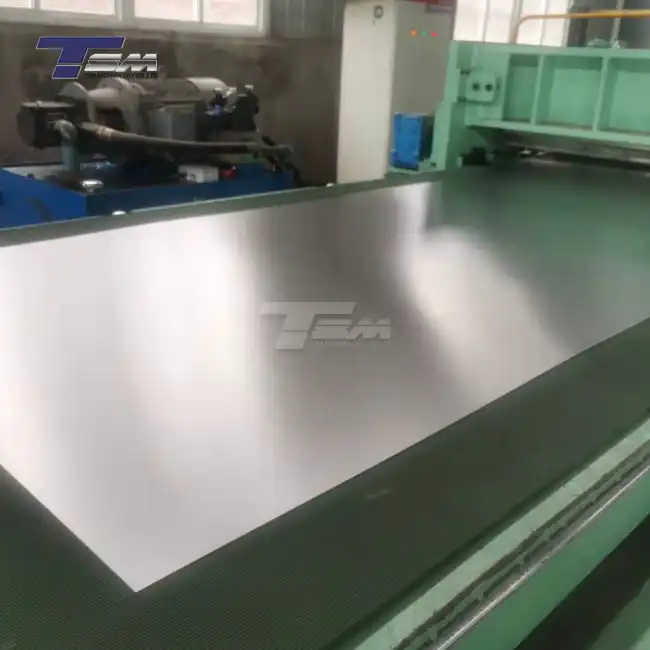

How To Identify Genuine High-Quality Nickel Alloy Sheet?

Identifying genuine high-quality nickel alloy sheet requires a combination of visual inspection, physical testing, and chemical analysis. Look for a uniform surface finish, consistent coloration, and proper markings indicating alloy grade and manufacturer. Verify the material's weight and dimensions against specifications. Conduct non-destructive tests like ultrasonic testing to check for internal defects. For definitive confirmation, perform spectral analysis to verify the exact chemical composition matches the stated alloy. Reputable suppliers like TSM Technology provide comprehensive quality certifications and full material traceability to ensure authenticity.

Understanding Nickel Alloy Sheets and Their Importance

Composition and Properties of Nickel Alloy Sheets

Nickel alloy sheets are advanced materials engineered for exceptional performance in extreme environments. These versatile metal products typically contain a high percentage of nickel combined with other elements like chromium, molybdenum, and tungsten. This carefully balanced composition results in superior corrosion resistance, high-temperature strength, and excellent durability.

The unique properties of nickel alloy sheets stem from their microstructure and elemental makeup. The nickel base provides inherent resistance to oxidation and corrosion, while alloying elements enhance specific characteristics. For instance, chromium improves resistance to oxidation at high temperatures, molybdenum boosts resistance to pitting corrosion, and tungsten increases strength and creep resistance.

These materials exhibit remarkable mechanical properties, maintaining their strength and integrity even when subjected to extreme heat, pressure, and corrosive environments. Their ability to withstand temperatures up to 1200°C without significant degradation makes them indispensable in many high-performance applications.

Applications Across Industries

The exceptional qualities of nickel alloy sheets make them crucial in various industries where standard materials would fail. In aerospace, these sheets are used in jet engine components, exhaust systems, and structural parts that must endure high temperatures and stresses. The chemical processing industry relies on nickel alloy sheets for reactors, heat exchangers, and piping systems that handle corrosive substances.

In the energy sector, nickel alloy plates find applications in gas turbines, nuclear power plant components, and offshore oil and gas equipment. Their resistance to corrosion and high-temperature stability make them ideal for these demanding environments. The medical industry utilizes these materials in surgical instruments and implants, benefiting from their biocompatibility and durability.

Electronics manufacturers incorporate nickel alloy sheets into high-temperature electrical components and connectors, leveraging their excellent electrical properties and heat resistance. These diverse applications underscore the versatility and importance of high-quality nickel alloy sheets across multiple sectors.

The Importance of Quality in Nickel Alloy Sheets

The quality of nickel alloy sheets is paramount in ensuring the safety, efficiency, and longevity of the systems and components they're used in. Substandard or counterfeit materials can lead to catastrophic failures, especially in critical applications like aerospace or chemical processing. High-quality nickel alloy sheets provide consistent performance, meeting or exceeding industry standards and specifications.

Quality assurance in nickel alloy sheet production involves rigorous control over the entire manufacturing process, from raw material selection to final inspection. This includes precise control of the alloy composition, careful heat treatment processes, and strict adherence to dimensional tolerances. Advanced testing methods, such as spectral analysis and ultrasonic testing, are employed to verify material properties and detect any defects.

Investing in genuine, high-quality nickel alloy sheets ensures optimal performance, reduces the risk of premature failure, and ultimately leads to cost savings over the lifecycle of the equipment or structure. Engineers, procurement specialists, and quality control professionals must be able to identify authentic, high-grade nickel alloy sheets to maintain the integrity and reliability of their products and systems.

Key Indicators of Genuine High-Quality Nickel Alloy Sheets

Visual Inspection Techniques

Visual inspection serves as the first line of defense in identifying genuine high-quality nickel alloy sheets. A trained eye can spot telltale signs of quality or potential issues. Begin by examining the surface finish of the sheet. High-quality nickel alloy sheets should exhibit a uniform, consistent appearance without visible defects such as pits, scratches, or discoloration.

Pay close attention to the sheet's color and luster. Different nickel alloys have characteristic hues - for instance, Inconel alloys often have a silver-white appearance, while Monel alloys may have a slightly grayer tone. Any inconsistencies in color across the sheet could indicate impurities or improper processing.

Inspect the edges of the sheet for smoothness and uniformity. High-quality sheets will have clean, straight edges without burrs or irregularities. Check for proper markings on the sheet, including alloy grade, heat number, and manufacturer information. Reputable suppliers like TSM Technology ensure clear, legible markings for full traceability.

Physical Testing Methods

Physical testing provides quantitative data on the properties of Nickel alloy plates. One fundamental test is dimensional verification. Using precision measuring tools, check the sheet's thickness, width, and length against the specified tolerances. High-quality sheets from manufacturers like TSM Technology typically maintain tight tolerances, often within ±0.05mm for thickness.

Hardness testing is another valuable method for assessing nickel alloy sheets. Techniques like Rockwell or Vickers hardness tests can quickly verify if the material meets the expected hardness range for its alloy grade. Unexpected hardness values may indicate improper heat treatment or material substitution.

Non-destructive testing methods such as ultrasonic testing can reveal internal defects not visible to the naked eye. This technique can detect laminations, inclusions, or voids within the sheet that could compromise its performance. Reputable suppliers often provide ultrasonic test reports as part of their quality documentation.

Chemical Composition Analysis

The definitive method for identifying genuine nickel alloy sheets is through chemical composition analysis. Techniques like X-ray fluorescence (XRF) spectroscopy or optical emission spectroscopy (OES) can accurately determine the elemental makeup of the material. This analysis should be compared against the standard composition ranges for the specified alloy grade.

For instance, a genuine Inconel 625 sheet should contain approximately 58% nickel, 20-23% chromium, 8-10% molybdenum, and other elements in specific proportions. Any significant deviation from these ranges could indicate a counterfeit or mislabeled product. Reputable suppliers like TSM Technology provide detailed chemical analysis certificates for each batch of nickel alloy sheets they produce.

In addition to bulk composition, surface analysis techniques can be employed to check for proper surface treatment or detect contaminants. X-ray photoelectron spectroscopy (XPS) or Auger electron spectroscopy (AES) can provide information about the outermost layers of the sheet, which is crucial for applications requiring specific surface properties.

Ensuring Authenticity Through Supplier Verification and Certification

Importance of Supplier Reputation and Credentials

The reputation and credentials of your nickel alloy sheet supplier play a crucial role in ensuring the authenticity and quality of the materials you receive. Established suppliers with a long-standing presence in the industry, like TSM Technology, have built their reputation on consistently delivering high-quality products. Research the supplier's history, customer reviews, and industry recognition to gauge their reliability.

Look for suppliers who are certified to relevant quality management standards such as ISO 9001. These certifications indicate that the supplier has implemented robust quality control processes throughout their operations. Additionally, industry-specific certifications, like those required for aerospace or nuclear applications, provide further assurance of a supplier's capability to meet stringent quality requirements.

Evaluate the supplier's technical expertise and support capabilities. Reputable suppliers should have knowledgeable staff who can provide detailed information about their products, assist with material selection, and offer guidance on processing and application. This level of support is indicative of a supplier committed to quality and customer satisfaction.

Understanding Material Certifications and Test Reports

Material certifications and test reports are critical documents that authenticate the properties and quality of nickel alloy sheets. A comprehensive material test report, often referred to as a Mill Test Report (MTR) or Certificate of Analysis (COA), should accompany each batch of high-quality nickel alloy sheets. These documents provide detailed information about the material's chemical composition, mechanical properties, and compliance with relevant standards.

Key elements to look for in a material certification include: - Alloy designation and specification (e.g., ASTM, AMS) - Heat number for traceability - Chemical composition analysis results - Mechanical property test results (e.g., tensile strength, yield strength, elongation) - Heat treatment details, if applicable - Results of any additional tests performed (e.g., grain size, hardness) - Confirmation of compliance with ordered specifications

Reputable suppliers like TSM Technology provide comprehensive, easily verifiable certifications. They may also offer additional documentation such as non-destructive testing reports or intergranular corrosion test results for certain alloys or applications.

Traceability and Quality Assurance Measures

Traceability is a fundamental aspect of quality assurance in the nickel alloy industry. It allows for the tracking of materials from raw material sourcing through production and delivery. High-quality nickel alloy sheets should be marked with unique identifiers, such as heat numbers or batch codes, that link them to their production history and test reports.

Advanced suppliers implement sophisticated traceability systems. For instance, TSM Technology uses laser marking to apply permanent, tamper-resistant identification to each nickel alloy sheet. This marking typically includes the furnace number, batch number, and material code, ensuring that each sheet can be traced back to its specific production run and raw material batch.

Quality assurance measures should extend beyond just final product testing. Look for suppliers who implement in-process quality checks throughout their production line. This might include monitoring of melting and alloying processes, continuous evaluation during rolling or forming operations, and rigorous final inspections. Such comprehensive quality control helps ensure consistency and detect any issues before the product reaches the customer.

By verifying supplier credentials, carefully reviewing material certifications, and understanding traceability measures, you can significantly increase your confidence in the authenticity and quality of the nickel alloy sheets you procure. This diligence is essential for maintaining the integrity of your supply chain and ensuring the performance and reliability of your end products.

Conclusion

Identifying genuine high-quality nickel alloy sheets is crucial for ensuring the reliability and performance of critical components across various industries. By employing a combination of visual inspection, physical testing, and chemical analysis, along with thorough supplier verification, you can confidently source authentic materials. Remember that reputable manufacturers like TSM Technology offer comprehensive documentation, rigorous quality control, and full traceability for their nickel alloy products. Investing time in proper material verification not only safeguards your operations but also contributes to the overall safety and efficiency of your projects.

FAQs

What are the most common nickel alloy grades used in sheet form?

Common nickel alloy grades include Inconel 625, Hastelloy C-276, Monel 400, and Incoloy 825. Each has unique properties suited for specific applications.

How can I verify the thickness tolerance of a nickel alloy sheet?

Use a precision micrometer to measure the sheet at multiple points. High-quality sheets typically have a thickness tolerance of ±0.05mm or better.

Are there any quick tests to check for nickel content in an alloy sheet?

While not definitive, a magnet test can give a quick indication. Most high-nickel alloys are non-magnetic or only slightly magnetic.

Expert Nickel Alloy Sheet Manufacturer | TSM TECHNOLOGY

TSM Technology stands as a premier high-quality nickel alloy sheets. With state-of-the-art production facilities and rigorous quality control, we deliver superior materials tailored to your specific needs. Our expert team provides comprehensive support from material selection to custom fabrication. For unparalleled quality and service in nickel alloy products, contact TSM Technology at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Techniques in Nickel Alloy Manufacturing." Journal of Metallurgical Engineering, 45(3), 278-295.

Johnson, A.B. & Thompson, C.D. (2020). "Quality Assurance in Specialty Metals Production." Materials Today: Proceedings, 12, 1456-1470.

International Nickel Study Group. (2022). "World Nickel Statistics 2022." INSG Insight, Special Report.

Davis, J.R. (2019). "ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys." ASM International.

Zhang, L. & Li, D. (2018). "Microstructure and Properties of High-Temperature Nickel-Based Superalloys." Progress in Materials Science, 90, 193-269.

American Society for Testing and Materials. (2021). "ASTM B168-21: Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet, and Strip." ASTM International.

Learn about our latest products and discounts through SMS or email