- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Inspect the Quality of Monel 401 Forgings?

To check the quality of Monel 401 forgings, you need to look at their chemical makeup, their mechanical features, and how accurate their measurements are. To make these high-performance nickel-copper alloys, they need to be put through a lot of tests, such as spectrometric analysis, tensile strength proof, ultrasonic testing, and corrosion resistance assessment. If you check something the right way, you can be sure that it meets ASTM standards and will work at its best in marine, chemical processing, and industrial settings where material integrity is important for safety and longevity.

Understanding the Importance of Quality Inspection for Monel 401 Forgings

Monel 401 forgings are an important part of modern industrial engineering because they are very strong and don't rust. This makes them essential for use in chemical, naval, and industrial settings. These high-performance nickel-copper alloys are made up of about 63% nickel and 30% copper. Iron and manganese are added in small amounts to improve their structural qualities. In tough working conditions, it's important to know what chemicals are in them and how they behave mechanically to make sure the products stay intact.

You can't say enough good things about quality checking in business-to-business buying, especially when it comes to important parts that have to work in harsh conditions. Low-quality materials come with a lot of risks, such as catastrophic operating failures, unplanned downtime that can cost thousands of dollars an hour, and damage to relationships with suppliers that can't be fixed. People in charge of buying things and original equipment manufacturers (OEMs) expect nickel-copper alloy forgings to last for decades in harsh marine settings or chemical processing plants that are prone to corrosion.

Quality inspection is the most important part of lowering risks in industry procurement. Before being installed, each made part must pass strict performance standards through a series of thorough tests. This proactive method stops expensive failures in the field and makes sure that expensive equipment works as it should. Both manufacturers and end users count on the reliability of the materials they use, so thorough inspection procedures are an important part of professional purchasing.

Key Quality Parameters to Inspect in Monel 401 Forgings

When judging the quality of nickel-copper alloy forgings, a few key factors that affect their long-term performance and dependability are used. Verification of the chemical composition is the first checkpoint. Spectrophotometric analysis shows that the percentages of elements meet the requirements. Nickel content is usually between 63 and 70%, copper content is between 28 and 34%, and iron and manganese levels are kept at a maximum of 2.5% and 2.0%, respectively, to ensure the best metallurgical qualities.

Chemical Composition Analysis

Spectrometric testing gives an exact analysis of the elements of Monel 401 forgings that proves the authenticity of a material and its grade compliance. Advanced optical emission spectroscopy and X-ray fluorescence methods find small amounts of elements that might hurt performance. To keep corrosion resistance, the carbon content must stay below 0.15%. To keep embrittlement resistance, the sulfur and phosphorus amounts must be strictly controlled. These methods of analysis make sure that the results are the same from batch to batch and that they meet international standards like ASTM B564 and ASME SB564.

Mechanical Property Verification

Forged parts are strong and flexible enough for their intended uses, as shown by mechanical tests. Tensile strength testing confirms that the minimum standards are met (550–750 MPa), and yield strength testing makes sure that materials can handle operational stresses without permanently deforming. Measurements of elongation show ductility traits important for shock loading situations common in naval and industrial settings.

Corrosion Resistance Assessment

Through sped-up lab procedures, corrosion testing mimics how things are exposed in the real world. ASTM B117 salt spray tests check for resistance to seawater, and chemical immersion tests check for performance in reducing acids and alkaline solutions. These tests give numbers that show how long something is supposed to last in different types of environments, which helps people choose the right materials.

Step-by-Step Process to Inspect the Quality of Monel 401 Forgings

Using systematic inspection procedures makes sure that all aspects of quality control are looked at, while also keeping things running smoothly. First, the documentation and eye examination are looked over. Then, testing methods that are more complex are used. Each step builds on the ones that came before it to make a full quality profile that helps people make sure decisions about what to buy.

Initial Documentation and Visual Inspection

The material certification review makes sure that the paperwork that was sent for Monel 401 forgings fits the specifications that were ordered. This paperwork should include the necessary mill test certificates (MTC) and third-party inspection reports. Visual inspection finds surface irregularities, differences in dimensions, and clear flaws that could mean there were problems during production. Using standard visual inspection criteria, trained testers look for cracks, inclusions, a good surface finish, and the right identification markings.

Chemical and Mechanical Testing Protocols

For tests in the lab, strict sampling rules are used to make sure that the results are the same for all batches. To make sure that the composition is uniform, chemical analysis needs several samples from different parts of big forgings. According to ASTM standards, specimens for mechanical testing are machined, and certified technicians use calibrated tools to do the testing. Controls over temperature and surroundings make sure that tests are accurate, and thorough records keep track of all the results.

Non-Destructive Testing Methods

Techniques for non-destructive testing (NDT) find flaws inside a component without damaging it. Ultrasonic testing finds flaws below the surface, like holes, inclusions, and laminations, that could cause the material to fail early. Liquid penetrant screening finds cracks in the surface that can't be seen with the naked eye. When it's possible, magnetic particle tests can find discontinuities close to the surface of ferromagnetic materials. These methods give you faith in the internal soundness of the system while keeping the value of the parts.

Heat Treatment Validation and Microstructural Analysis

Through hardness tests and microstructural examinations, heat treatment proof makes sure that the metal is in the right metallurgical state. Rockwell hardness tests prove that the right levels of strength have been reached, while metallographic analysis shows the structure of the grains, how the phases are distributed, and any possible heat treatment flaws. These tests show that thermal processing got the qualities that were wanted without damaging the microstructural features.

Comparing Monel 401 Forgings with Alternative Alloys for Informed Decision-Making

Procurement professionals can make cost-effective choices that meet performance standards when they know about the different options for materials. Monel 401 is better than regular stainless steels and other nickel alloys in many ways. It is especially useful in naval and chemical processing settings where resistance to corrosion is very important. Comparative analysis looks at performance traits, cost factors, and the unique needs of the application to help choose the best material.

Monel 401 versus Monel 400 Performance

When compared to regular Monel 400, Monel 401 has better mechanical properties. It is stronger and hardens more quickly, which is good for high-stress uses. Adding aluminum to Monel 401 forgings in a controlled way causes precipitation hardening, which gives the metal higher tensile strength and wear resistance. Both of these alloys are very good at resisting corrosion, but Monel 401 is better for important parts that are subject to high mechanical loads because it has better mechanical qualities.

Stainless Steel Alternatives and Limitations

Austenitic stainless steels, such as 316L, are less expensive and good at resisting rust, but they don't work as well in seawater as nickel-copper alloys. Chloride-induced stress corrosion cracking is still a big problem for marine uses that use stainless steels. On the other hand, Monel alloys are very good at not breaking down in this way. Even though duplex stainless steels are stronger, they can't compete with Monel materials when it comes to performance in harsh marine settings.

Ensuring Reliable Procurement: Supplier Evaluation and Order Management

To get high-quality nickel-copper alloy forgings, you need to be careful when choosing suppliers and handle your orders well. Qualified suppliers show consistent quality performance through thorough certification programs and production skills that have been proven. With three state-of-the-art factories that have eight production lines and more than 100 machines, TSM Technology sets the bar for the industry. The company can supply 300 tons of goods every month and has full vertical integration, which includes vacuum arc furnaces and 2,500-ton forging presses.

Supplier Certification and Quality Systems

Manufacturers with a good reputation keep a number of certificates, such as ISO 9001 quality management systems, AS9100D aerospace standards, and NADCAP special process approvals. These certifications show that you are dedicated to quality control and improvement methods that are always getting better. Supplier audits check that quality processes work well while also looking at the company's ability to make things, the accuracy of its testing equipment, and the qualifications of its employees.

Supply Chain Management and Lead Time Optimization

Through strategic planning and partnerships with suppliers, good supply chain management finds a balance between the cost of inventory and the dependability of delivery. Knowing how long it usually takes to make forged parts helps you plan your projects better and spot possible problems before they cause delays. TSM Technology's strategic raw material reserves and global supply chain security keep the company stable when market conditions change.

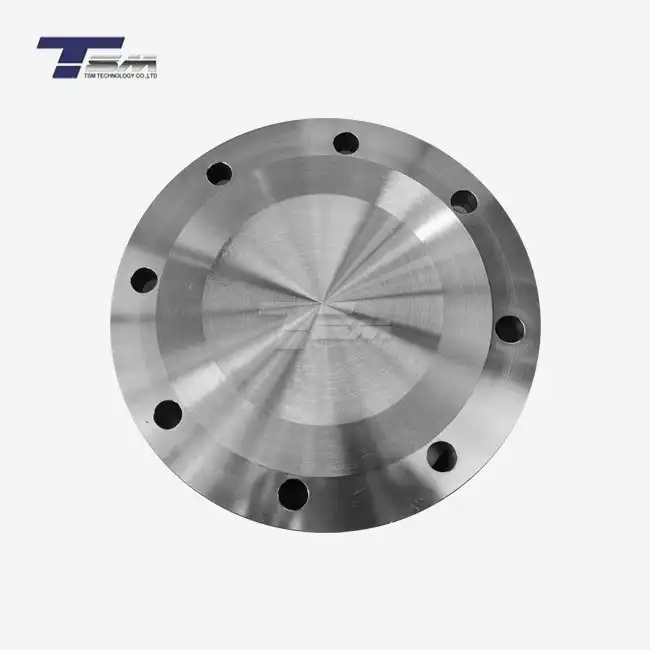

Smart warehousing and transportation systems at the company make sure that orders are processed quickly and that everything can be tracked from the raw materials to the final delivery. Customization options support OEM requirements for weights between 1 kg and 500 kg in a range of shapes, such as rings, shafts, flanges, and custom geometries. Both open die and closed die forging can be used to meet different production needs while still keeping the same level of quality.

Conclusion

To make sure that Monel 401 forgings work well in tough situations, they need to be checked for quality by looking at their chemical makeup, mechanical properties, and size and shape. Comprehensive testing procedures, such as spectrometric analysis, mechanical testing, and non-destructive examination, help buyers feel confident in the quality of the materials they are buying and make smart decisions about what to buy. By understanding the relative benefits of different alloys, you can choose the best material for your specific needs. Partnering with qualified suppliers who show consistent quality performance through certified manufacturing methods and full testing capabilities is key to successful procurement.

FAQs

1.What international standards must Monel 401 forgings meet?

Monel 401 forgings must comply with ASTM B564, ASME SB564, and DIN 17743 standards, which specify chemical composition, mechanical properties, and testing requirements. Additional standards like JIS, AISI, GB, and EN may apply depending on regional requirements and specific applications.

2.How often should quality inspections be performed during production?

Quality inspections should occur at multiple stages including raw material receipt, after forging operations, following heat treatment, and before final shipment. Critical applications may require 100% inspection, while statistical sampling plans can be appropriate for less critical components based on supplier quality history.

3.Are Monel 401 forgings suitable for harsh marine environments?

Yes, Monel 401 forgings excel in marine applications due to exceptional seawater corrosion resistance and immunity to chloride-induced stress corrosion cracking. Their proven performance in offshore platforms, marine propulsion systems, and seawater handling equipment makes them ideal for harsh marine environments.

4.What testing methods verify the internal soundness of forgings?

Ultrasonic testing provides comprehensive evaluation of internal soundness by detecting voids, inclusions, and laminations within forged components. Radiographic examination may supplement ultrasonic testing for critical applications, while liquid penetrant inspection reveals surface-breaking defects.

5.How long do quality certifications remain valid?

Material test certificates typically remain valid indefinitely when components are properly stored and handled. However, re-certification may be required if materials are exposed to contamination, undergo additional processing, or when traceability documentation is questioned.

Partner with TSM Technology for Premium Monel 401 Forgings

TSM Technology stands ready to support your procurement requirements with industry-leading Monel 401 forgings manufactured to the highest quality standards. Our comprehensive quality assurance system, backed by ISO 9001, AS9100D, and NADCAP certifications, ensures every component meets your exact specifications. As a trusted Monel 401 forgings supplier with over a decade of experience, we provide complete material certification including MTC and SGS test reports, customized sizing, and free samples to support your evaluation process. Contact our technical experts at info@tsmnialloy.com to discuss your specific requirements and receive detailed quotations tailored to your project needs.

References

Davis, J.R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." ASM International Materials Handbook, 2000.

Friend, W.Z. "Corrosion of Nickel and Nickel-Base Alloys in Marine Environments." NACE International Publication, 1995.

Peckner, D. and Bernstein, I.M. "Handbook of Stainless Steels: Chapter 15 - Nickel-Copper Alloys." McGraw-Hill Engineering Reference, 1977.

ASTM International. "Standard Specification for Nickel-Copper Alloy Forgings." ASTM B564-19, Annual Book of ASTM Standards, 2019.

Rebak, R.B. "Environmental Degradation of Materials in Nuclear Power Systems." TMS Conference Proceedings on Corrosion in Nuclear Applications, 2018.

Tuthill, A.H. "Guidelines for the Use of Copper Alloys in Seawater Applications." Copper Development Association Technical Report, 2017.

Learn about our latest products and discounts through SMS or email