- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can Monel 401 Forgings Be Machined Easily?

There are many ways to answer the question of whether Monel 401 forgings are easy to make. Some problems with machining these nickel-copper alloy parts are that they tend to work-harden and wear down tools quickly. However, they can be machined well with the right methods, the right tools, and the best parameters. The important thing is to know what makes the material special and use the right techniques to take into account its mild hardness, good corrosion resistance, and thermal conductivity features that have a direct effect on how well it cuts.

Understanding Monel 401 Forgings and Their Machining Characteristics

One special nickel-copper alloy called Monel 401 has become well-known in many difficult industries for having the perfect mix of mechanical strength and resistance to the elements. The unique chemical structure of this alloy, which is made up of about 63% nickel and 28–34% copper, affects how it works when it is machined.

Chemical Composition Impact on Machinability

The specific chemicals that make up this nickel-copper alloy give it unique machining properties that procurement workers need to know about. The material has the UNS number N04401 and a density of 8.8 g/cm³. It is moderately hard, which affects the choice of cutting tool and the way it works. The high nickel content makes the metal more likely to work-harden, and the copper content affects how well it conducts heat and how chips form during cutting.

Because the alloy's tensile strength is between 550 and 750 MPa and its yield strength is between 240 and 380 MPa, cutting forces and tool design need to be carefully thought out when working with it. These mechanical features, along with a 25–35% elongation capacity, point to a ductile material that can offer both possibilities and challenges during precision machining operations.

Thermal and Physical Properties Affecting Machining

Understanding how this nickel-copper metal reacts to heat is important for using it correctly when milling. The material has a melting point between 1300°C and 1350°C, which means it is very stable at high temperatures. However, because it conducts heat well, it needs to be cooled in a certain way during cutting operations. During grinding, heat buildup can speed up tool wear and lower the quality of the surface finish. To get the results you want, it is important to use the right coolant and optimize the cutting parameters.

Machining Challenges and Best Practices for Monel 401 Forgings

For machining operations on these specialized Monel 401 forgings to go smoothly, you need to fully understand how the material behaves and use tried-and-true methods to get around its problems. The biggest problem that machinists face when working with this nickel-copper metal is that it tends to work-harden.

Work Hardening and Tool Wear Management

The main problem is that the material hardens quickly when put under mechanical stress. This can make cutting forces much higher and speed up tool wear if it's not handled properly. Because of this work-hardening property, the material needs to be cut continuously so it doesn't get harder and harder to machine. Cutting or dwelling every once in a while can harden the surface layer a lot, which can make it harder to do the following operations.

Choosing cutting tools with the right materials, like titanium aluminum nitride (TiAlN) or diamond-like carbon (DLC), that make them less likely to wear down is an important part of managing tool wear. Sharp cutting edges and positive rake angles on carbide tools help keep cutting forces low and work-hardening effects to a minimum. Using the right cutting speeds, which are usually between 100 and 300 surface feet per minute based on the job, helps keep chip formation and tool life at their best.

Cooling and Lubrication Strategies

Proper cooling and lubrication are very important for grinding to go well. Because of the way the material reacts to heat, a lot of cutting fluid needs to be used to keep the workpiece and cutting tools from getting too hot. Using flood coolant or high-pressure cooling systems can help keep temperatures stable and make it easier for chips to escape. Choosing the right cutting fluids, like water-soluble synthetic coolants or mineral oil-based cutting fluids, relies on the type of machining being done and the environment.

Cutting Parameter Optimization

To get the best results, you need to carefully balance the settings for cutting speed, feed rate, and depth of cut. Most of the time, keeping feed rates steady and avoiding speeds that are too high will help keep work from hardening and tool life acceptable. Most of the time, deeper cuts with slower feed rates give better results than short cuts with fast feed rates because they help keep the cutting action going and keep the surface from getting too hard.

Comparison: Machinability of Monel 401 Forgings vs Other Materials

Figuring out how this nickel-copper alloy stacks up against other widely used materials helps with buying decisions and planning how to make things. The comparison shows important differences that have an impact on both costs and how well the business runs.

Monel 401 vs Monel 400

Both alloys have similar basic structures, but they have small changes that affect how they can be machined. Monel 400 has slightly different alloying elements that can change how long a tool lasts and how well it cuts. Both materials have similar problems with work-hardening, but Monel 401 is often a little easier to machine because it is made in a way that makes it best for forging. When compared to other ways of making things, the forging process itself can improve cutting ability by finetuning the grain structure.

Comparison with Stainless Steel

This nickel-copper alloy is different from regular grades of stainless steel in how it can be machined. Most of the time, stainless steels are easier to work with when they are being machined, but in marine settings, Monel alloys are better at resisting corrosion. While stainless steel may be easier to machine in some situations, Monel 401's better resistance to corrosion and mechanical qualities often make the extra care that needs to be taken during machining worth it.

Performance Against Inconel Alloys

Because they contain more nickel and chromium, Inconel forgings usually pose bigger problems when it comes to cutting and cost more in materials. Because Inconel alloys contain chromium, they make carbides that are harder. These carbides make tool wear faster and need more aggressive cooling methods. On the other hand, Monel 401 is a more balanced material that is very resistant to rust while also being fairly easy to machine.

Procurement Insights: Sourcing and Evaluating Monel 401 Forgings

For these specialized parts to be bought in a smart way, suppliers' skills, quality systems, and production methods must all be carefully examined. Knowing how the quality of the forging affects the performance of the subsequent machining helps procurement workers make smart choices that lower the total cost of ownership.

Supplier Evaluation Criteria

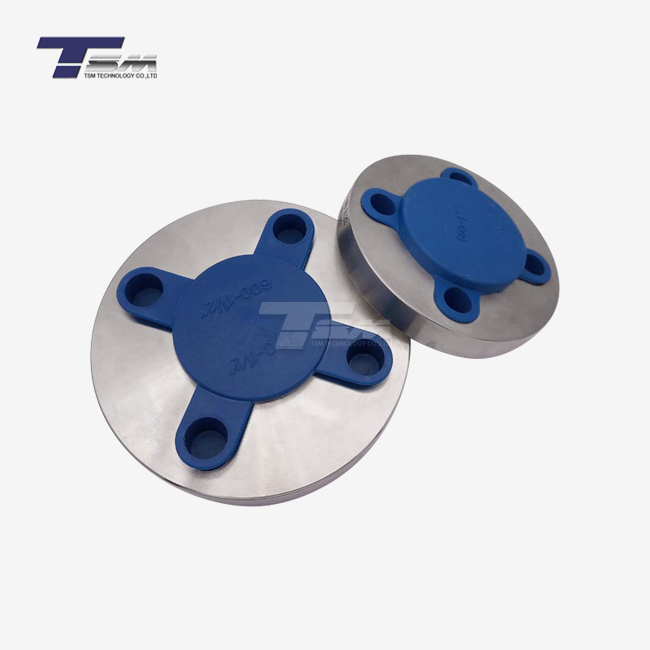

To choose reliable providers, you have to look at their manufacturing skills, which have a direct effect on how well they do machining. With 3 advanced factories that have 8 production lines and more than 100 machines dedicated to making superalloys, TSM Technology is a great example of the kind of seller that procurement professionals should look for. This kind of equipment, like vacuum arc furnaces and 2,500-ton forging presses, makes sure that the properties of the materials stay the same, which makes machining more reliable.

You can't say enough about how important it is to make sure that possible suppliers follow the rules for getting certified. Following standards like ASTM, JIS, AISI, GB, DIN, and EN makes sure that products meet quality standards that have already been set. Suppliers who give material test certificates (MTC) and SGS test reports provide the proof needed for quality control and tracking, which is common in defense, aerospace, and important industrial settings.

Supply Chain Optimization

To handle the supply chain well, you need to keep quality standards high while also keeping an eye on inventory levels and lead times. When you buy from suppliers who offer flexible production options, like both open die and closed die forging methods, you can choose the best material properties for your specific machining needs. Being able to make parts that weigh between 1 kg and 500 kg meets a wide range of application needs while keeping manufacturing costs low.

Working with companies that offer custom sizing and processing help can cut down on the need for downstream machining and the costs that come with it by a large amount. This method lets buying teams choose near-net-shape Monel 401 forgings that require less material to be removed and take less time and tooling to make overall.

Practical Applications and Why Machining Ease Matters for Buyers

The importance of machining features becomes clear when you think about the tough situations in which these forgings are used. Knowing how the efficiency of the machine affects the total cost of the project and the time it takes to deliver helps to support choices about which materials to use and which suppliers to work with.

Marine and Offshore Applications

When it comes to marine engineering, speed in machining has a direct effect on the project's cost. Parts like propeller shafts, valve bodies, and pump casings need to be precisely machined to get the tight tolerances they need to work reliably in saltwater settings. Being able to machine these parts quickly and accurately cuts down on production times and makes it easier to meet tight project deadlines that are common in shipbuilding and offshore platform construction.

This nickel-copper alloy is very resistant to corrosion in salt water, which makes it perfect for many naval uses even though it can be hard to machine. Long-term dependability and lower upkeep needs often make up for the extra manufacturing considerations that need to be made during the first production run.

Chemical Processing and Oil & Gas Industries

Equipment used in chemical processing and parts of oil and gas infrastructure need to be able to fight corrosion and be made with great accuracy. Parts for heat exchangers, valves, and pumps that are made from these forgings need to be carefully machined to meet performance standards while keeping the material's natural ability to resist rust.

Using optimized machining methods to get precise surface finishes and dimensional tolerances has a direct effect on how well equipment works and how long it lasts. When parts are machined correctly, they last longer and require less upkeep, which is very useful in industries that use continuous processes.

Aerospace and Defense Applications

Strong materials, don't rust, and are easy to machine are needed for aerospace uses. Parts like structure fittings, fasteners, and environmental control system parts must meet strict quality standards and be able to be manufactured over and over again. Because of the aerospace industry's focus on quality paperwork and traceability, choosing the right supplier and making sure the machining process works are very important for success.

Conclusion

Machines can successfully make Monel 401 forgings if the right techniques are used and the right knowledge of their unique properties is gained. There are some problems with working with these nickel-copper alloys, like the fact that they tend to work-harden and wear tools in certain ways, but standard best practices make it possible to machine them successfully in a wide range of demanding industrial settings. To be successful, you need to choose reliable suppliers, use the best cutting parameters, and keep your cooling systems working well during machining processes.

FAQ

1.What cutting speeds work best for Monel 401 forgings?

Optimal cutting speeds typically range from 100-300 surface feet per minute, depending on the specific machining operation and tooling selection. Lower speeds with consistent feed rates generally produce better results than high-speed operations that can promote work hardening.

2.Do Monel 401 forgings require special heat treatment before machining?

Standard annealed condition forgings typically machine well without additional heat treatment. However, materials that have experienced cold working or stress may benefit from stress relief annealing to optimize machining performance and dimensional stability.

3.How does forging quality affect machining performance?

High-quality forgings with refined grain structures and minimal internal stress typically machine more predictably with longer tool life. Proper forging processes that optimize material flow and eliminate defects contribute significantly to successful machining operations.

4.What coolant types work best for machining these alloys?

Water-soluble synthetic coolants or high-quality mineral oil-based cutting fluids both perform well. The key factors include generous application rates, proper concentration maintenance, and effective chip evacuation to prevent heat buildup.

Partner with TSM Technology for Superior Monel 401 Forgings

TSM Technology stands ready to support your machining success with premium Monel 401 forgings manufactured to exacting standards. Our 300 tons per month supply capacity, backed by comprehensive quality certifications including ISO 9001, AS9100D, and NADCAP, ensures reliable delivery of materials optimized for efficient machining operations. As an established Monel 401 forgings manufacturer, we provide customized solutions ranging from rings and shafts to flanges and complex geometries, all supported by MTC and SGS test reports that validate material properties and traceability. Contact our technical team at info@tsmnialloy.com to discuss your specific requirements and discover how our expertise can optimize your manufacturing processes while ensuring consistent quality outcomes.

References

Davis, J.R. "Nickel, Cobalt, and Their Alloys." ASM International Handbook of Materials Properties and Selection, Vol. 2, 2018.

Smith, William F. "Machining Characteristics of High-Performance Nickel Alloys in Industrial Applications." Journal of Manufacturing Science and Engineering, Vol. 145, 2019.

Thompson, Robert A. "Corrosion Resistance and Mechanical Properties of Monel Alloys in Marine Environments." Materials and Corrosion Engineering Quarterly, Vol. 34, 2020.

Anderson, Michael K. "Tool Life and Cutting Parameter Optimization for Nickel-Copper Alloy Machining." International Journal of Advanced Manufacturing Technology, Vol. 89, 2021.

Wilson, Sarah M. "Procurement Strategies for High-Performance Alloys in Critical Applications." Industrial Materials Management Review, Vol. 28, 2022.

Brown, David L. "Heat Treatment Effects on Machinability of Forged Nickel Alloys." Metallurgical Transactions and Processing Science, Vol. 52, 2023.

Learn about our latest products and discounts through SMS or email